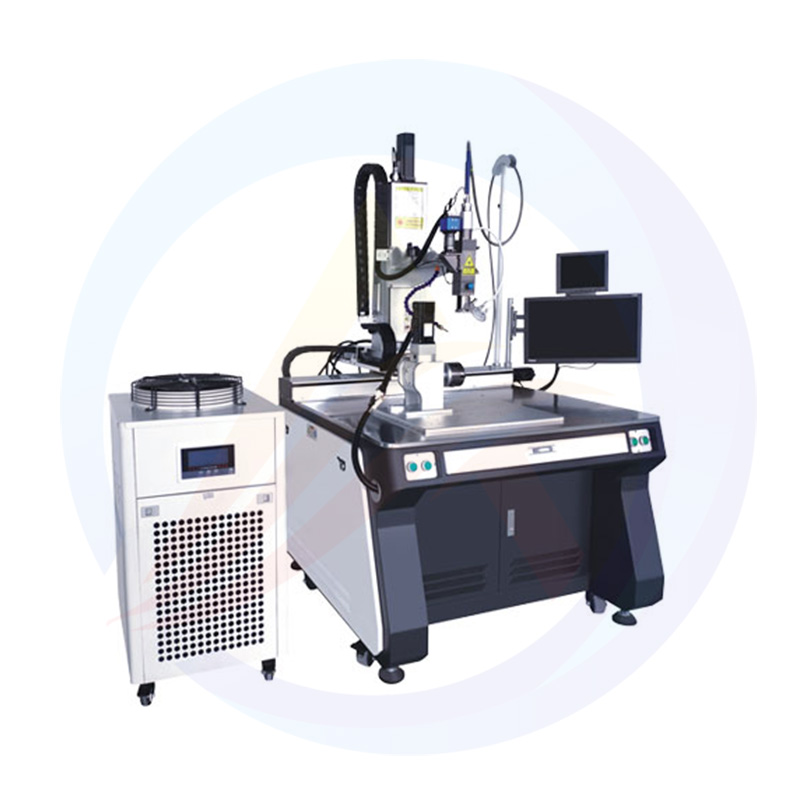

Lithium Battery Laser Spot Welder Welding Machine For 18650

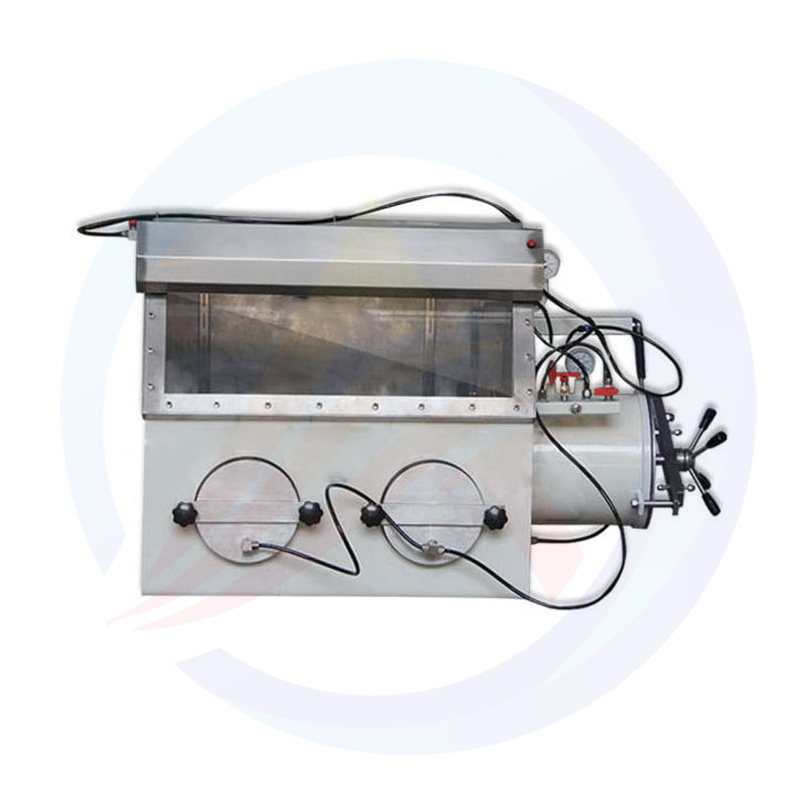

Laser spot welding machine

● The mini laser spot welding machine beam quality is excellent, the welding speed is fast, and the weld seam is firm and beautiful.

● Controlled by an industrial PC, the workpiece of this lithium battery spot welding machine can make plane trajectory movement, and it can weld points, straight lines, circles, squares, or any plane graphics composed of straight lines and arcs;

● Our battery spot welder welding machine for 18650, featuring high electro-optical conversion rate, low energy consumption, and long-term use can save users a lot of processing costs;

● The spot welding machine for the 18650 battery has high reliability and can be processed continuously and stably for 24 hours, meeting the needs of industrial mass production and processing;

laser spot welding machinemini laser spot welding machinelithium battery spot welding machinebattery spot welder welding machine for 18650spot welding machine for 18650 battery

Email

More