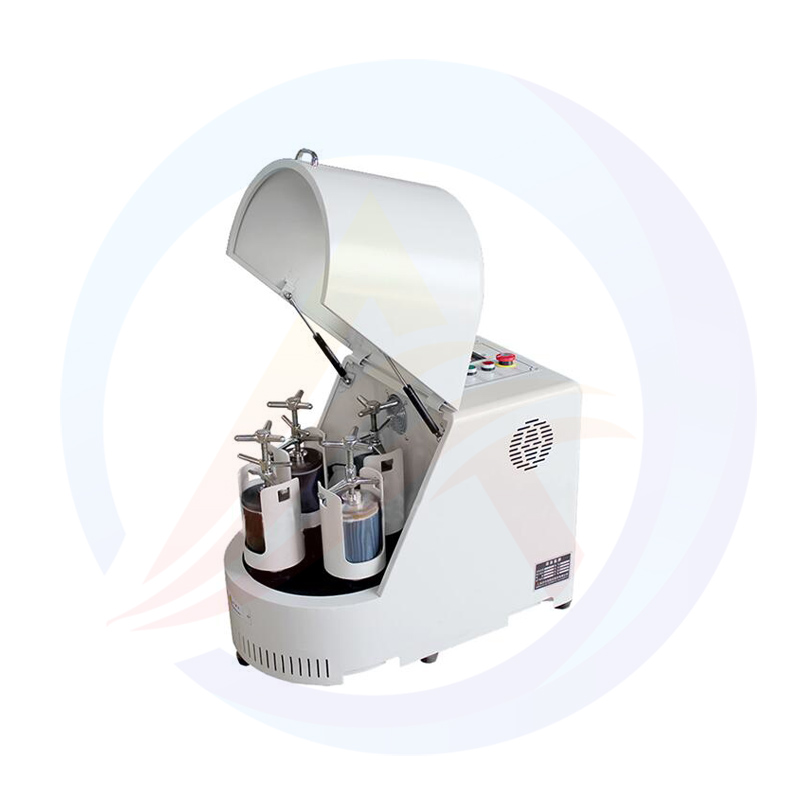

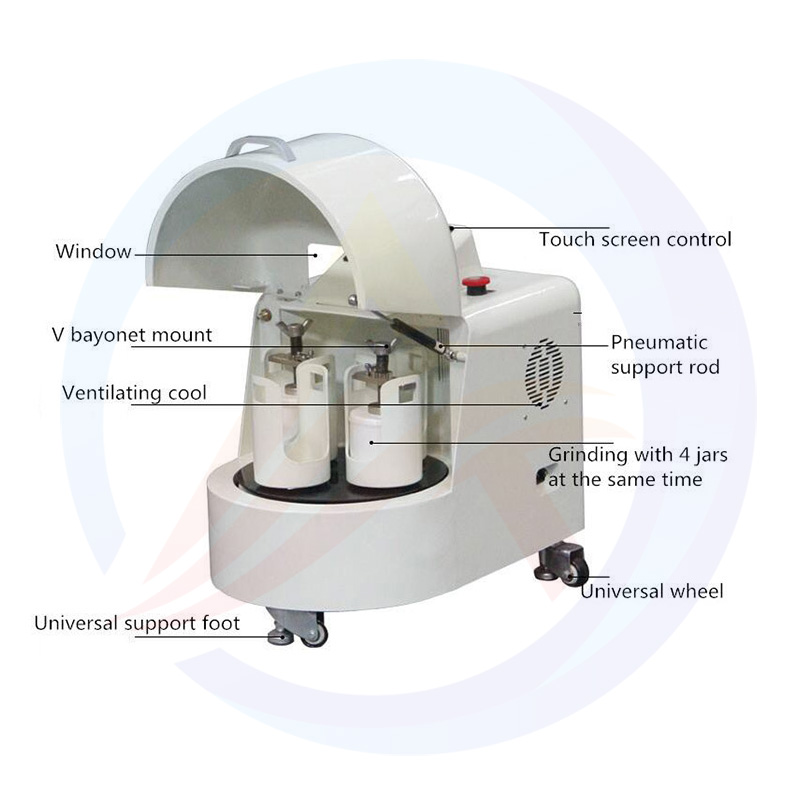

Planetary Ball Mill Milling Machine For Laboratory

Advantages of planetary ball mill:

1. A planetary ball mill is necessary for mixing, fine grinding, sample preparation, nano-materials dispersing, new product development, and preparing small-volume high-tech material production.

2. The planetary ball mill is small, full-featured, high efficiency, and low noise which is the ideal equipment for scientific research units, institutions of higher learning, and corporate laboratories to obtain microparticle research samples. (Four samples for each experiment).

3. Planetary ball mill can be equipped with a vacuum ball mill; the sample can be ground under a vacuum. It is widely used in geology, mining, metallurgy, electronics, building materials, ceramics, chemicals, light industry, medicine, beauty, environmental protection, and other departments.

4. It can set the speed, forward and reverse rotation time, and the total grinding time according to process requirements.

5. The small volume can be worked in the glove box.

planetary ball millplanetary ball mill for laboratoryplanetary ball mill machineplanetary ball milling machine

Email

More