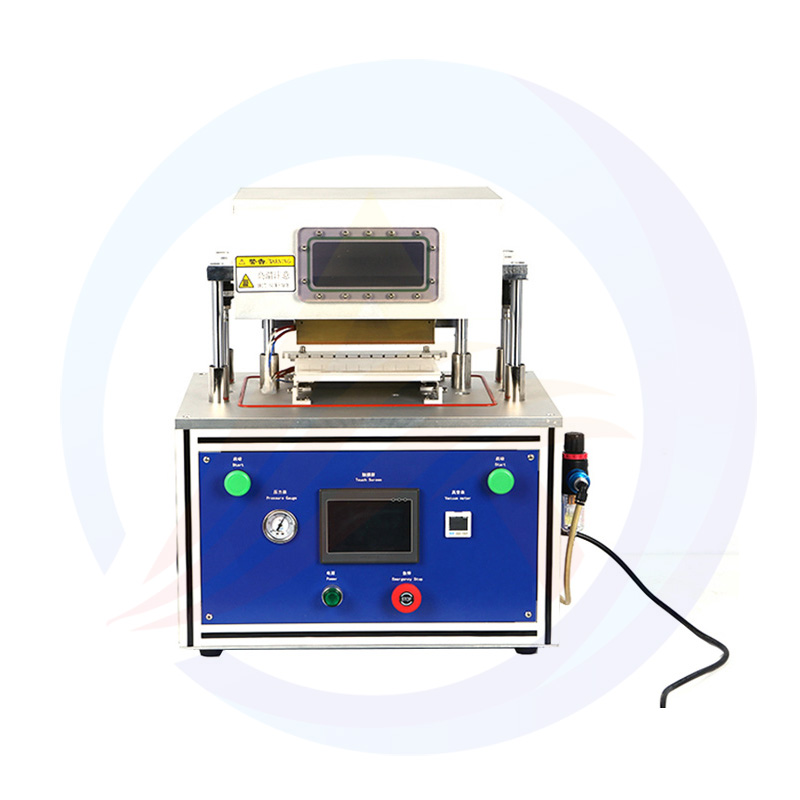

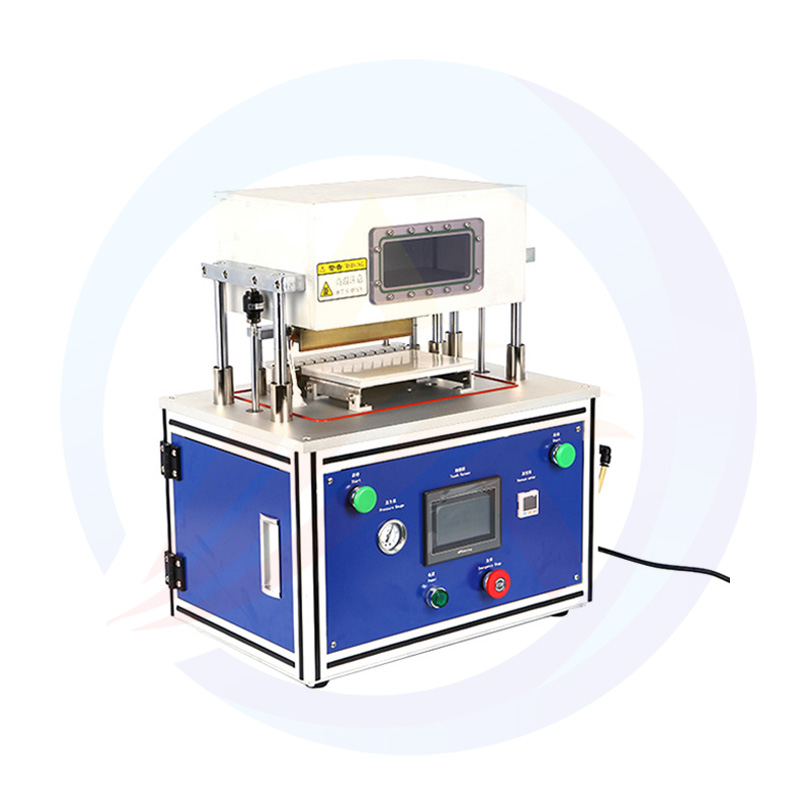

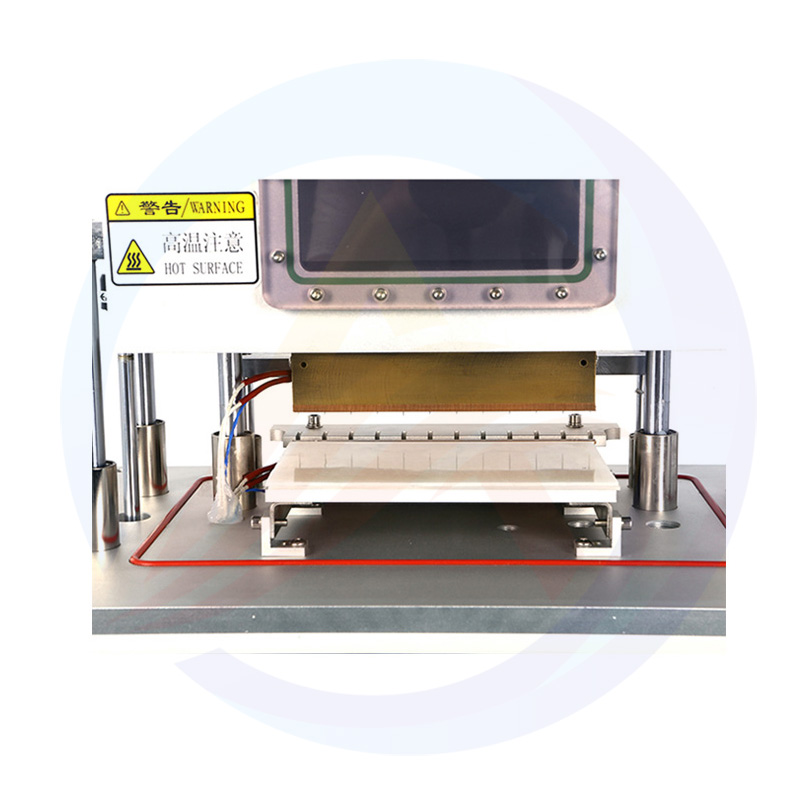

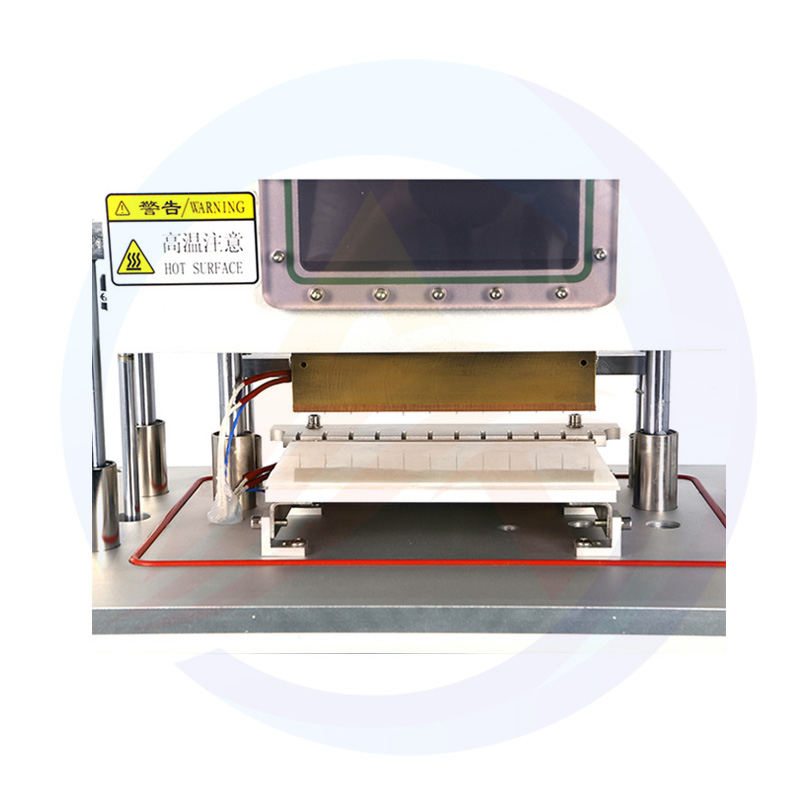

Consistent and reliable sealing:

The vacuum sealer machine applies uniform pressure and heat to ensure consistent and reliable sealing results for each pouch cell, minimizing defects and ensuring optimal performance.

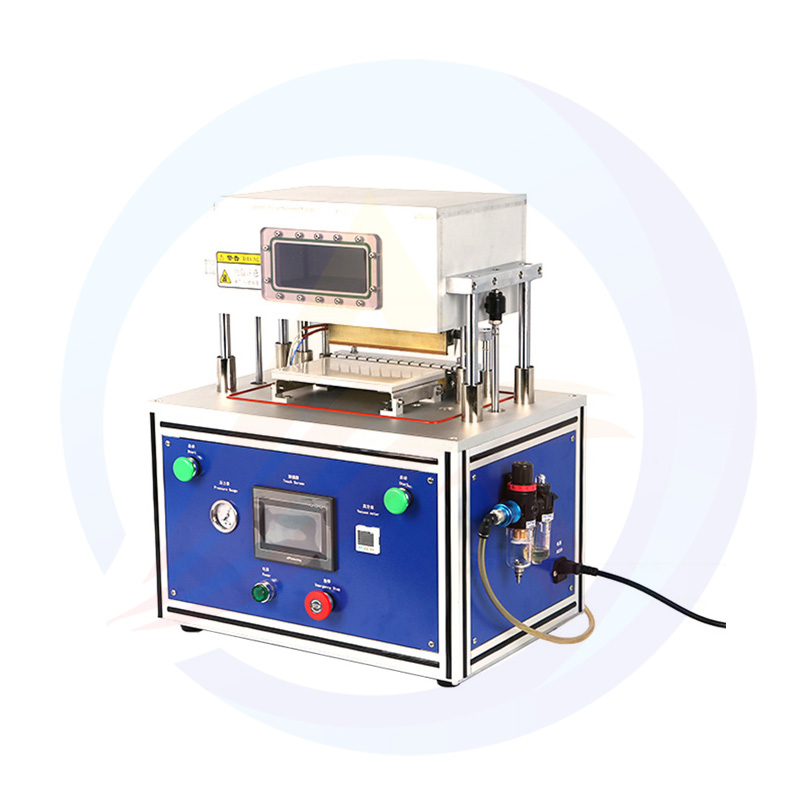

Customizable sealing parameters:

The vacuum sealer machine allows for adjustable sealing parameters such as temperature, pressure, and sealing time, enabling users to optimize the sealing process for different pouch cell materials and requirements.

User-friendly operation:

The vacuum sealer machine is designed with user-friendly interfaces and controls, making it easy to operate, monitor, and maintain.