-

Home

-

Products

- Ball Mill

- Lab Furnace

- Battery Mixer Machine

- Battery Coating Machine

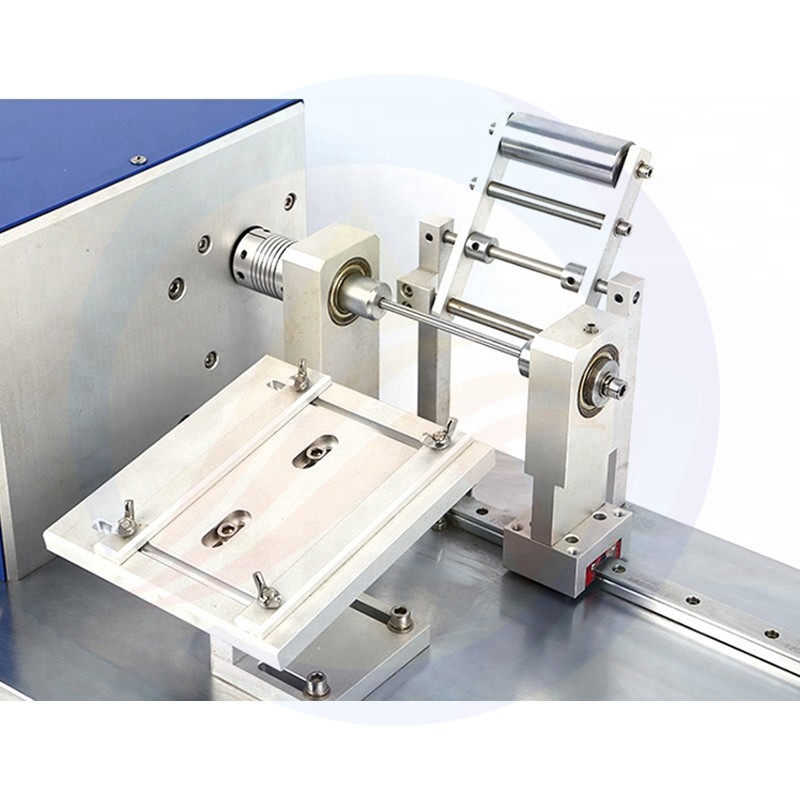

- Roller Press

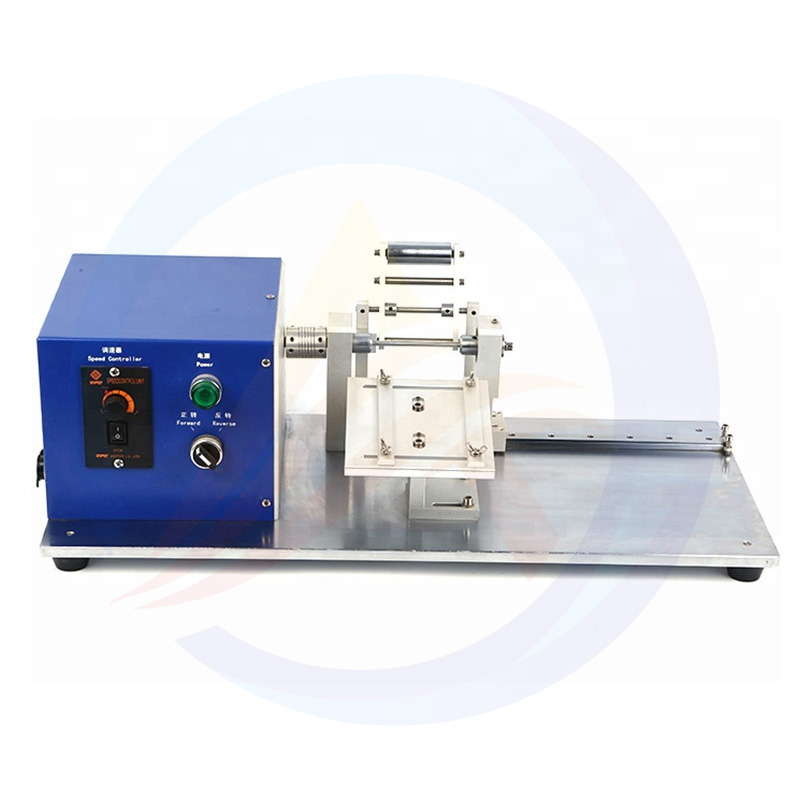

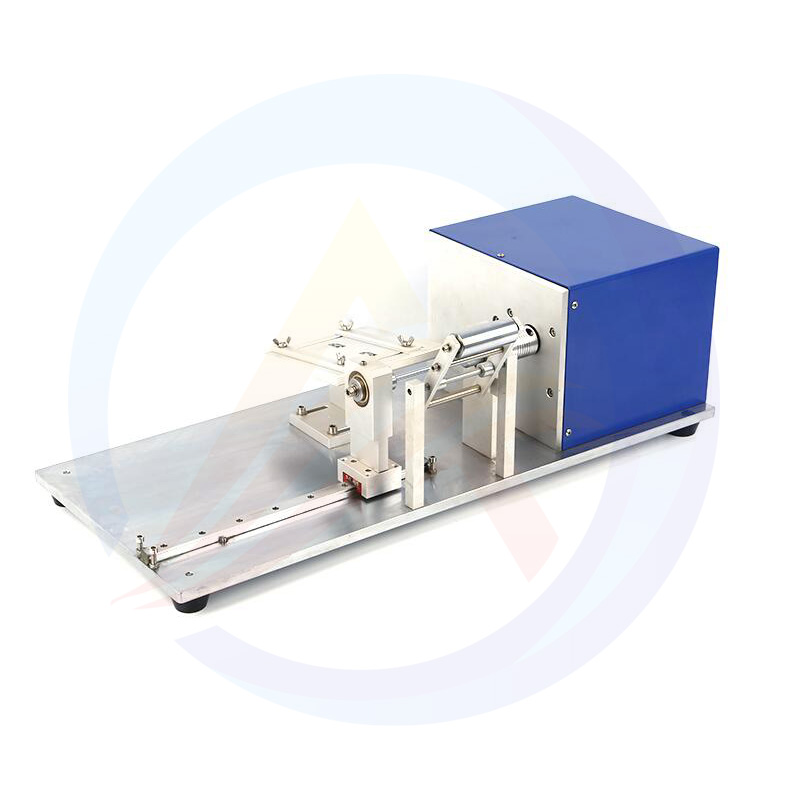

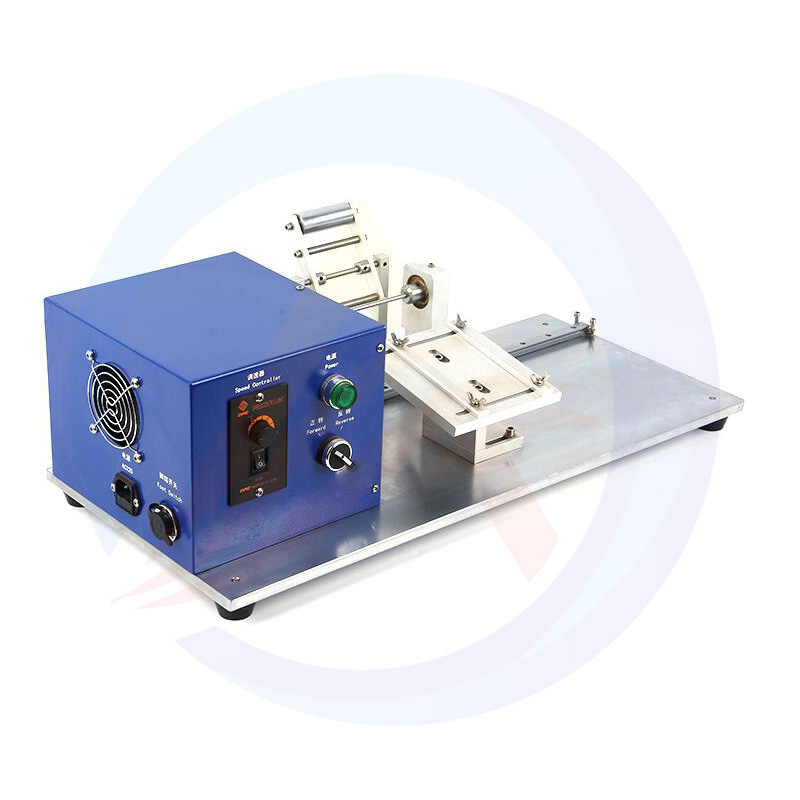

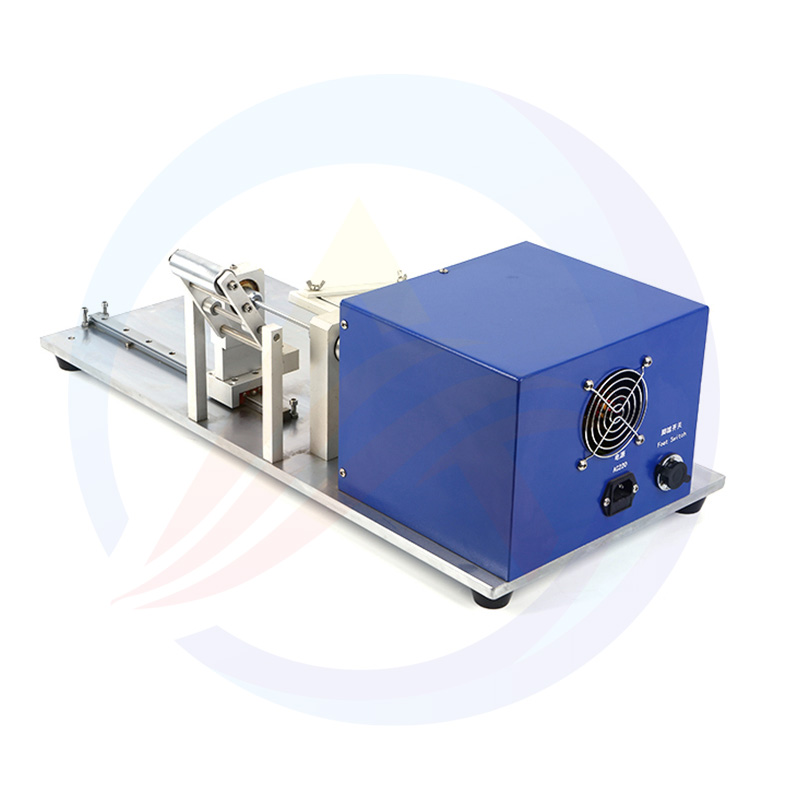

- Electrode Slitting Machine

- Electrode Die Cutting Machine

- Battery Stacking Machine

- Battery Winding Machine

- Battery Sealing Machine

- Battery Spot Welding Machine

- Vacuum Glove Box

- Battery Tester

- Cylindrical Battery Pack Assembly Machine

-

Drying Oven

-

News

- Case

- Factory Show

-

Contact Us

- About Us

-

Videos