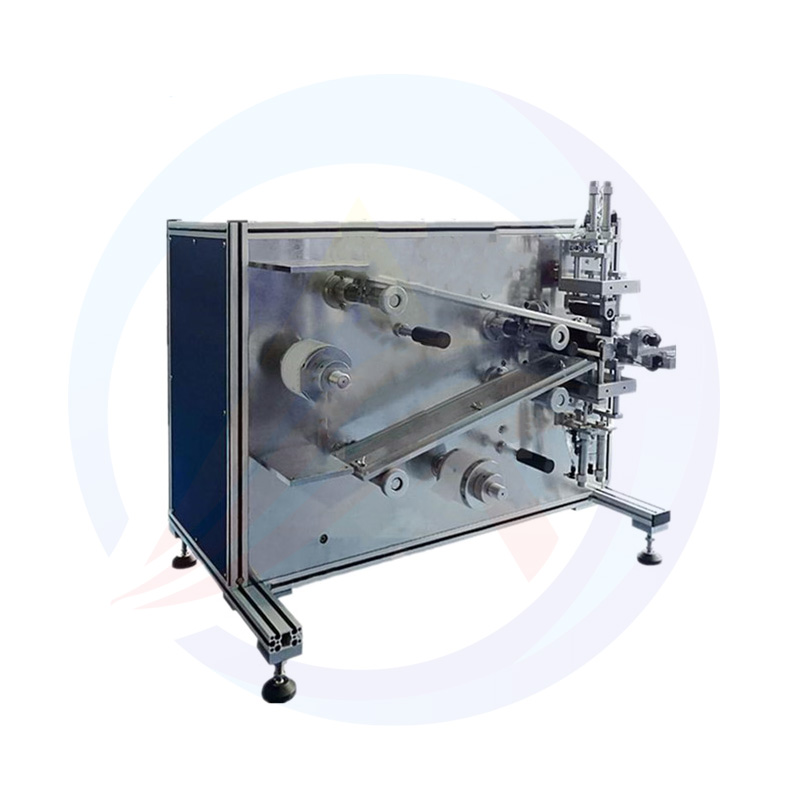

| Voltage | AC220V,1.5KVA,50HZ |

| Compressed air | 0.4-0.6MPa |

| Productive capacity | 8PCS/min |

| Weight | About 500kg |

| Size | 1660mm*1300mm*1570mm (Does not include the outstretched length of the electrode.) |

| Winding needle specification | ø1.5mm-ø9mm(With one set for free, customized) |

| The applicable outer diameter of the cell | ø12mm-ø32mm |

| Equipment capacity: | 6~15 pcs/ min (according to the length/width of the electrode) |

| Winding precision | when the electrode is guaranteed to meet the following conditions:

The width error is less than ±0.2mm

The bending error of "S" is less than ±1mm/500mm;

The tower shape error of the separator is less than ±0.2mm; |

| The winding precision can be satisfied | The alignment error of the separator is less than ±0.5mm;

The alignment error of the electrode is less than ±0.5mm;

It can be realized the negative electrode wraps the cathode electrode, the separator wraps the negative electrode, and the alignment of the finished product section is ±0.5mm |

| Qualified rate | ≥98% (excluding equipment factors) |

| Warranty | One Year limited warranty with lifetime support |