Working Principle And Application Of Lithium Battery Stacking Machine

Battery Stacking Machine, an essential piece of equipment in the battery manufacturing process, specializes in the efficient stacking of battery cells or components into battery packs or modules. This automation solution significantly enhances production efficiency and ensures product consistency, catering to the growing demands of the battery industry, particularly in the fields of electric vehicles, energy storage systems, and consumer electronics.

1. Key Features and Functionality

1.1 Automation and Precision

The Battery Stacking Machine employs advanced automation technologies, including robotic arms, precision sensors, and servo motors, to accurately pick, position, and stack battery cells with minimal human intervention. This ensures high precision and repeatability in the stacking process.

1.2 Versatility

Capable of handling various types of batteries, such as lithium-ion, nickel-metal hydride, and lead-acid, the machine can be customized to meet specific production requirements. It supports different battery sizes, shapes, and electrode configurations.

1.3 Efficiency Boost

By automating the stacking process, the machine significantly reduces production time and labor costs. It enables high-volume production with consistent quality, enhancing overall efficiency and profitability.

1.4 Quality Control

Integrated quality control mechanisms, including vision systems and sensors, ensure that each battery pack is assembled correctly and meets predetermined quality standards. Defective cells or improperly stacked packs are detected and removed from the production line.

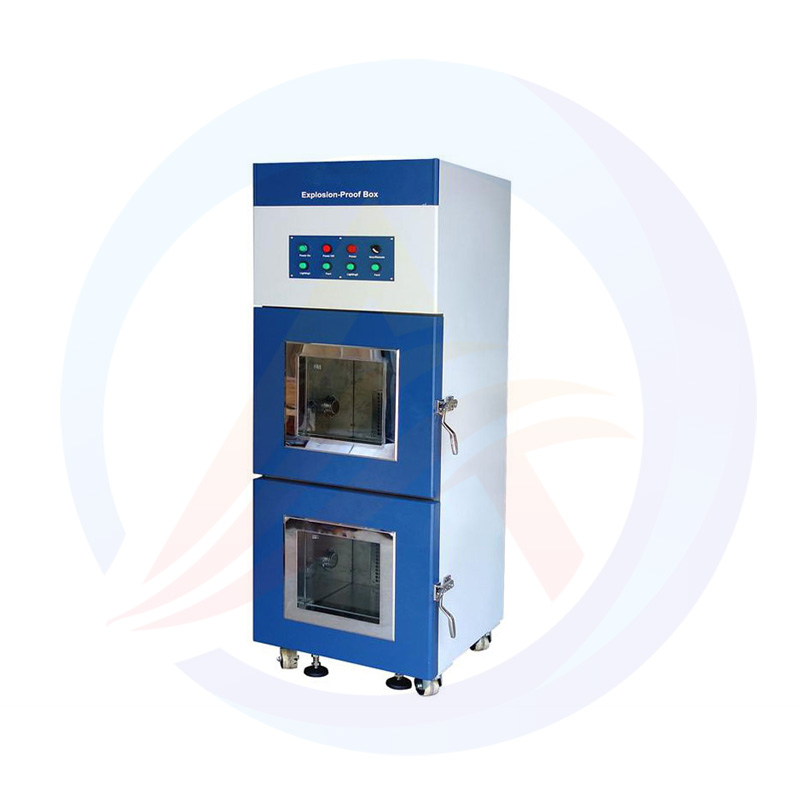

1.5 Safety Measures

The Battery Stacking Machine is designed with safety features that minimize the risk of accidents during operation. These include emergency stop buttons, protective guards, and safety interlocks to prevent unauthorized access to hazardous areas.

1.6 Customization and Integration

Manufacturers often offer customization options to tailor the machine to specific production lines and processes. It can be integrated seamlessly into existing battery manufacturing systems, facilitating a smooth and efficient workflow.

2. Working Principle

The Battery Stacking Machine operates on a series of automated steps that involve the following key processes:

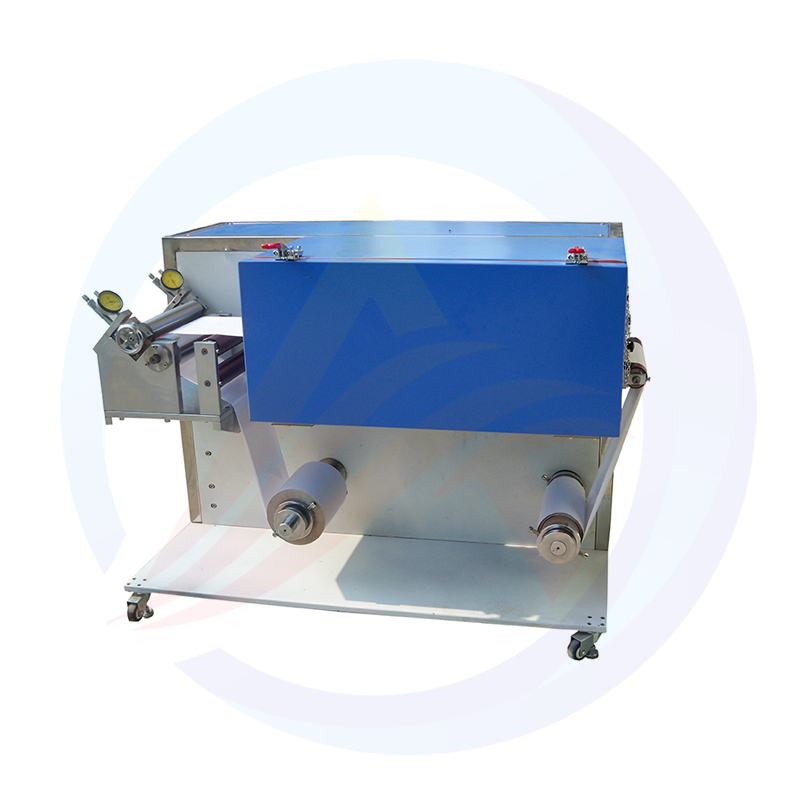

2.1 Feeding and Alignment

Battery cells are fed into the machine through a dedicated inlet system. Precision alignment mechanisms ensure that each cell is oriented correctly for stacking.

2.2 Picking and Placement

A robotic arm or similar mechanism is used to pick up individual battery cells from the feeding system. The arm then precisely places the cells onto a conveyor belt or stacking platform, following a predetermined pattern or sequence.

2.3 Stacking and Compression

As the battery cells are stacked, compression mechanisms may be applied to ensure tight packing and reduce the risk of cell movement during subsequent operations.

2.4 Electrode Connection (Optional)

For battery packs that require electrode connections, the machine may include a welding or crimping station to connect the electrodes of adjacent cells.

2.5 Quality Inspection

Completed battery packs undergo a thorough quality inspection process, including visual checks and possibly electronic testing, to ensure that they meet the required specifications.

2.6 Output and Packaging

Finally, the battery packs are conveyed to an output station for further processing or packaging. Depending on the production line, they may be automatically packaged or prepared for manual packaging.

Battery Stacking Machine finds extensive applications across various industries where battery production and assembly are critical. Its versatility and automation capabilities make it an indispensable tool in enhancing production efficiency and quality. Here are some key application scenarios for the Battery Stacking Machine:

1) Electric Vehicle (EV) Industry:

In the EV sector, the Battery Stacking Machine is used to assemble battery packs for electric cars, buses, and other vehicles. These battery packs, consisting of multiple battery cells, require precise stacking and connection to ensure optimal performance and safety.

2) Energy Storage Systems (ESS):

For large-scale energy storage solutions, such as utility-scale batteries and home energy storage systems, the Battery Stacking Machine automates the process of stacking battery cells into modules and packs. This helps in achieving high energy density and reliability for long-term storage applications.

3) Consumer Electronics:

Portable devices like smartphones, tablets, and laptops often require custom battery packs with specific shapes and sizes. The Battery Stacking Machine can be customized to stack battery cells into the desired configurations, meeting the unique demands of the consumer electronics industry.

4) Industrial Equipment:

In industries that rely on battery-powered equipment, such as forklifts, drones, and robotic systems, the Battery Stacking Machine is used to produce high-capacity and high-performance battery packs. These packs need to be reliable and durable to support continuous operation in various industrial environments.

5) Renewable Energy:

For renewable energy projects, such as solar and wind power systems, energy storage is crucial for balancing supply and demand. The Battery Stacking Machine plays a vital role in assembling large-scale battery banks that store excess energy generated by these renewable sources.

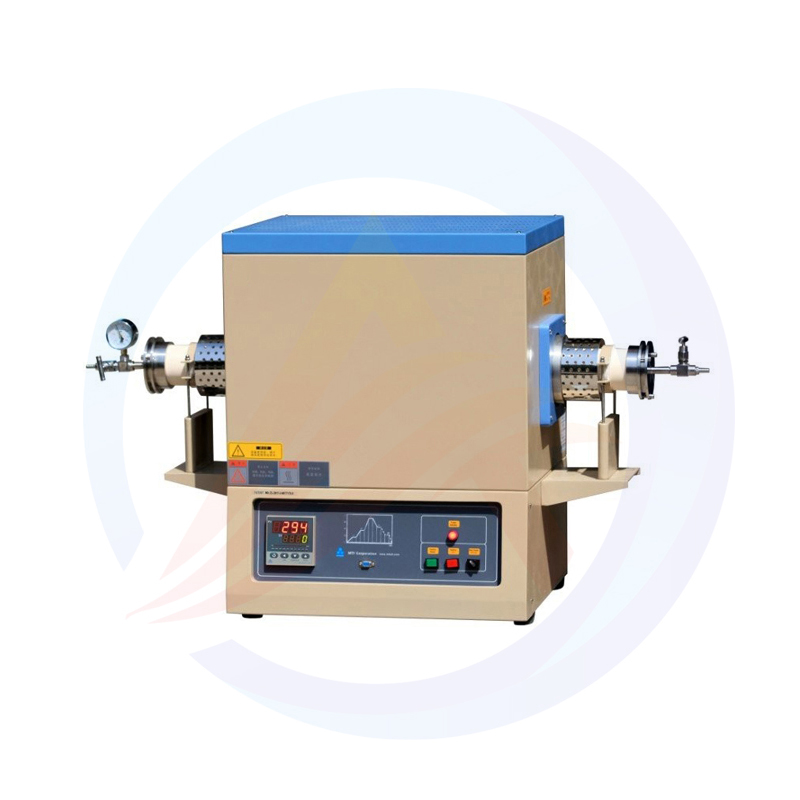

6) Research and Development (R&D):

In the R&D phase of battery technology, the Battery Stacking Machine enables researchers and engineers to quickly prototype and test new battery designs. Its flexibility and precision allow for the experimentation of various cell configurations and stacking patterns.

7) Battery Recycling and Repurposing:

Although not its primary application, the Battery Stacking Machine can also be adapted for use in battery recycling and repurposing processes. It can assist in disassembling used battery packs and stacking the recovered cells or materials for further processing or reuse.

In each of these scenarios, the Battery Stacking Machine contributes to increased production throughput, improved product quality, and reduced labor costs. Its automation and precision capabilities make it a valuable addition to any battery manufacturing or assembly line.