1, what is lithium battery coating machine

2, the importance of lithium battery coating machine

3, the role of lithium battery coating machine

4, lithium battery coating machine operation process

5, the development of lithium battery coating machine

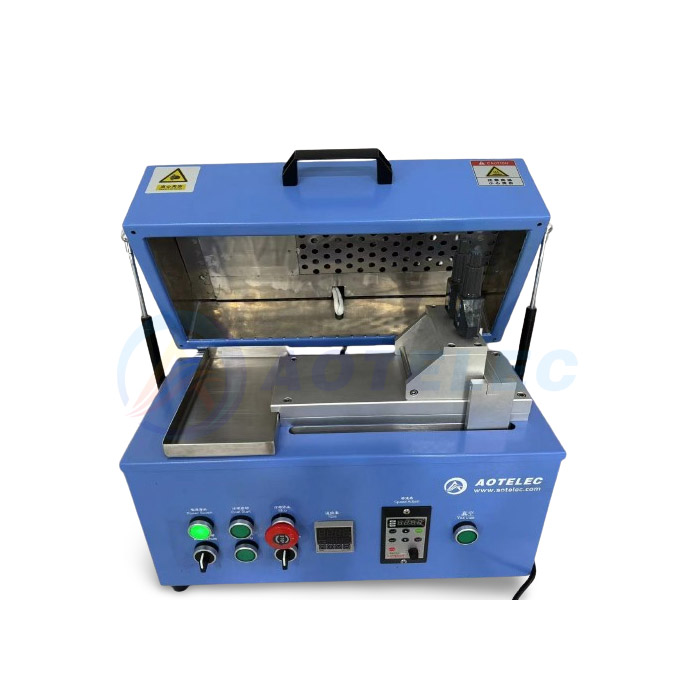

1, what is lithium battery coating machine

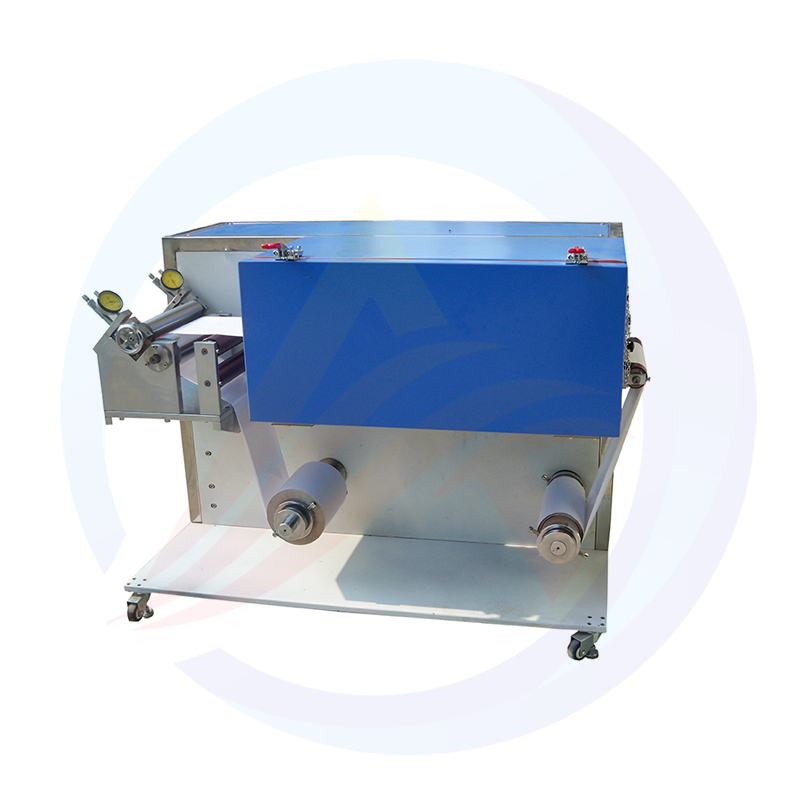

Lithium battery coating machine is a key equipment specially used to evenly coat the positive and negative slurry of lithium battery on metal foil or film. The core component is the coating head, which ensures the uniform distribution of the slurry by precisely controlling the coating gap. The unit is also equipped with an advanced drying system that effectively vaporizes the solvent in the slurry, leaving behind a solid component. Lithium battery coating machine has the characteristics of high precision, high speed and high efficiency, which can meet the needs of large-scale production, and is widely used in the battery manufacturing field of mobile phones, computers, electric vehicles and so on. At the same time, its structure is simple and easy to operate, and it is also suitable for other industries that need coating technology, such as plastic coating, paper coating and so on.

2, the importance of lithium battery coating machine

Lithium battery coater occupies a pivotal position in the new energy industry, and is one of the core equipment in the lithium battery manufacturing process. With the rapid development of electric vehicles, portable electronic devices and energy storage systems, the demand for high-performance and high-safety lithium batteries is growing, and the coating process directly determines the energy density, cycle life and safety performance of the battery.

Lithium battery coating machine through precision control, the positive and negative electrode materials are uniformly and continuously coated on the collector fluid to form a uniform coating. This process not only requires extremely high accuracy and stability, but also ensures the uniformity of material distribution and the firmness of interlayer bonding to optimize the electrochemical performance of the battery. Therefore, advanced coating technology is crucial to improve the overall performance of lithium batteries.

3, the role of lithium battery coating machine

First of all, the lithium battery coating machine is a key device to ensure battery performance. It is responsible for uniformly and accurately coating positive and negative active substances on the collector fluid, which directly determines the core performance indicators such as energy density, power output and cycle life of the battery. By precisely controlling coating thickness, speed and material uniformity, the coater can significantly improve the overall performance of the battery and meet the high requirements of different application scenarios.

Secondly, lithium battery coating machine plays an important role in improving production efficiency. Modern coater usually has a high degree of automation and intelligence, which can achieve a continuous and stable production process and reduce manual intervention, thereby greatly improving production efficiency. At the same time, through real-time monitoring and feedback adjustment, the coating machine can also respond to abnormal conditions in the production process in time to ensure the stable operation of the production line.

In addition, the lithium battery coating machine also has a positive significance for reducing production costs. Efficient and precise coating processes reduce material waste and defective products, thereby reducing production costs. In addition, with the continuous progress of technology, the energy consumption of the coater is also gradually reduced, further reducing the production cost.

Finally, the lithium battery coating machine has also promoted the rapid development of the new energy industry. As one of the key links of lithium battery production, the performance and technical level of the coating machine directly affect the development of the entire new energy industry chain. With the growing demand for high-performance lithium batteries in fields such as new energy vehicles and energy storage systems, the coating machine industry is also constantly innovating and developing, injecting a strong impetus to the prosperity of the new energy industry.

4, lithium battery coating machine operation process

Equipment preparation: First, prepare the lithium battery coater to ensure that the equipment is intact and in normal condition. Check whether the nozzle and conveyor belt are clean and perform necessary cleaning. At the same time, ensure that the environment around the coating machine is dry to avoid dust and debris interfering with the operation.

Material preparation: Prepare the copper/aluminum foil substrate and suspension slurry of positive and negative active material according to coating requirements. Follow the paint brand and recipe instructions to add paint, make sure not to add too much or not enough, and stir paint to ensure an even mix.

Parameter setting: Turn on the power of the coater controller and enter the machine system interface. According to the coating model number, coating quality and coating requirements, set the appropriate flow, speed, spray rate, spray pressure and other parameters.

Coating operation: Start the conveyor belt and coating machine and feed the copper/aluminum foil substrate into the coating machine. After the base material passes through the tension control and automatic correction device, it enters the coating device for coating. During the coating process, according to the coating properties and coating requirements, the process parameters are adjusted to ensure the coating uniformity and coating quality.

Drying and winding: the coated wet pole sheet is sent to the drying channel for drying, and the drying temperature is set according to the coating speed and thickness. After drying, the dry electrode sheet is formed and rewound by tension control and automatic correction device.

Monitoring and maintenance: During the entire coating process, it is necessary to monitor the operating status of the equipment and the coating effect, and adjust the parameters in time to maintain a stable production process. At the same time, pay attention to the maintenance and maintenance of the equipment to ensure the normal operation of the equipment and extend the service life.

5, the development of lithium battery coating machine

The future prospect of lithium battery coater is very broad. With the rapid development of new energy vehicles, energy storage systems and consumer electronics products, lithium batteries as its core components, its production demand will continue to grow, thereby driving the continuous expansion of the lithium battery coater market.

Technological innovation will be a key factor in promoting the future development of lithium battery coater. In the future, the coating machine will develop in the direction of higher precision, higher efficiency and lower energy consumption to meet the increasing needs of lithium battery manufacturers for production processes and battery quality. At the same time, intelligence, automation and digitalization will also become an important trend in the development of coater, through the integration of advanced sensors, control systems and data analysis technology, to achieve intelligent monitoring and optimization of the coating process, improve production efficiency and product quality.

In addition, with the adjustment of the global energy structure and the enhancement of environmental awareness, the lithium battery coating machine industry will also face more opportunities and challenges. Enterprises need to pay close attention to market changes and policy and regulatory dynamics, and constantly innovate and optimize products to meet market demand and environmental protection requirements. At the same time, strengthening international cooperation and exchanges to promote the common development of the global lithium battery coating machine industry will also be an important direction of future development.