The rise of sodium-ion batteries in a new era of power batteries

Ushering in the age of sodium-battery electric cars

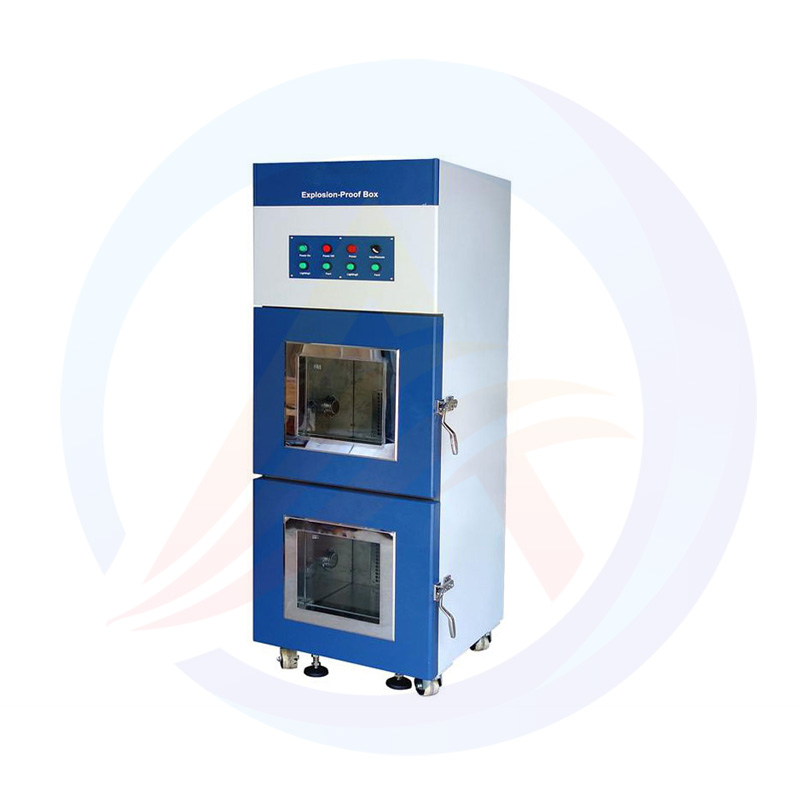

In early 2024, the world's first sodium-ion battery electric vehicle was officially delivered to users. The new car has a range of up to 252 kilometers and is equipped with 32,140 sodium ion cylindrical batteries. The cell adopts the technical route of "copper base like oxide + hard carbon", the monomer capacity is 12Ah, the energy density is more than 140Wh/kg, and it has the advantages of high safety, high energy density and good low temperature performance. In recent years, including Ningde Times, sodium Energy and other domestic enterprises have also accelerated the layout of sodium ion battery industry, has now achieved small batch production and performance evaluation, is expected to open the first year of the development of sodium battery tram in 24 years.

Sodium ion versus lithium-ion battery

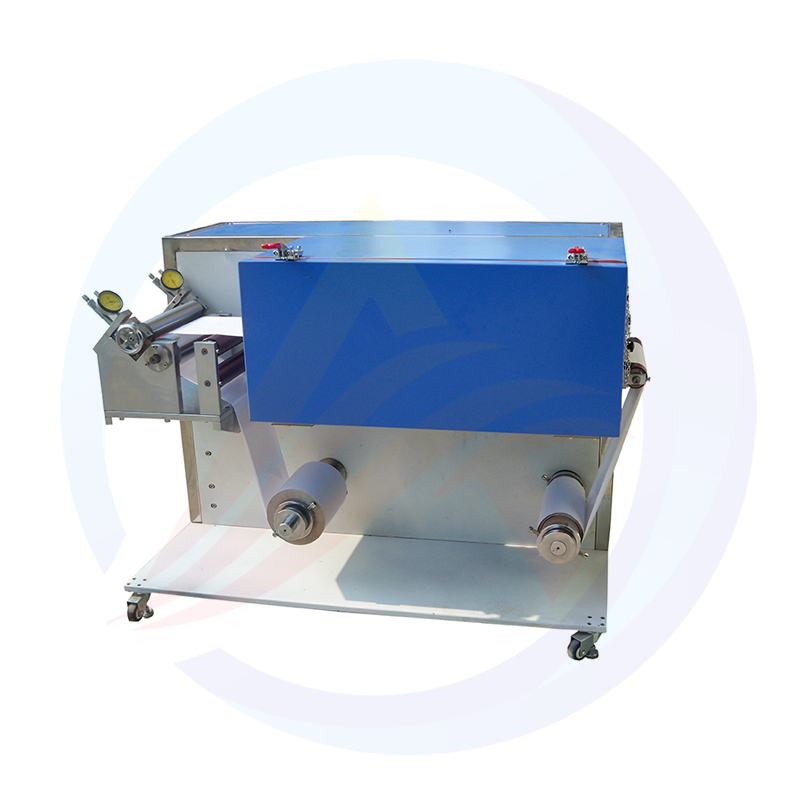

Sodium-ion batteries are expected to become another secondary battery technology for large-scale commercial applications because of their unique advantages. Compared with lithium-ion batteries, sodium ions have a stronger solvation interaction capacity and a smaller stokes radius, which enables low concentration sodium ion electrolyte solutions to achieve higher ionic conductivity. Since sodium and lithium belong to the same main group of adjacent elements, the two have a high similarity in chemical properties, so the working principle of sodium-ion batteries is similar to that of lithium-ion batteries, which follow the "rocking chair" mechanism. The sodium ion battery is composed of positive electrode, negative electrode, diaphragm, electrolyte and fluid collector. The charge and discharge process is realized by reversible embedding and deembedding of sodium ion between the positive and negative electrode materials. In the process of charging, sodium ions are removed from the positive electrode and embedded into the negative electrode to form a NA-poor positive electrode and a Na-rich negative electrode. In the discharge process, sodium ions are reversely embedded into the positive electrode from the negative electrode to achieve charge and discharge balance. Electrons are transferred in the external circuit, maintaining charge balance with the migration of sodium ions. Due to the characteristics of sodium-ion batteries, they are compatible with lithium-ion battery manufacturing equipment, which is less difficult to industrialization and has broad market prospects in the future.

In terms of energy density, the cell of a sodium-ion battery is usually in the range of 105-150wh/kg. The energy density of lithium-ion battery cells generally exceeds 190wh/kg, and some ternary systems with high Ni content even exceed 230wh/kg. Although the current sodium-ion battery can not yet be compared with the ternary lithium battery, but compared with the lithium iron phosphate battery 120-200wh/kg and the lead acid battery 35-45wh/kg, sodium-ion battery has a certain competitiveness. In terms of operating temperature range and safety, sodium-ion batteries have obvious advantages. Its operating temperature range is -40℃-80℃, while the operating range of ternary lithium-ion batteries is usually -20℃ ~ 60℃. In an environment below 0 ° C, the performance of lithium batteries will be affected. In contrast, sodium-ion batteries can still achieve more than 80% SOC retention at -20 ° C. In addition, due to the large internal resistance of sodium-ion batteries, they are not easy to heat, so they show higher safety in terms of thermal runaway. In terms of charging speed, sodium-ion batteries can be fully charged in just 10 minutes, compared to at least 40 minutes for ternary lithium batteries and 45 minutes for lithium iron phosphate. Overall, although the energy density cannot compete with lithium-ion batteries, sodium-ion batteries can well solve the two major pain points of current new energy vehicles in terms of low temperature stability and charging speed, and are still one of the choices considered by major car companies.

A brief analysis of the technical route of layered oxide for sodium ion batteries

Cathode material - layered transition metal oxide

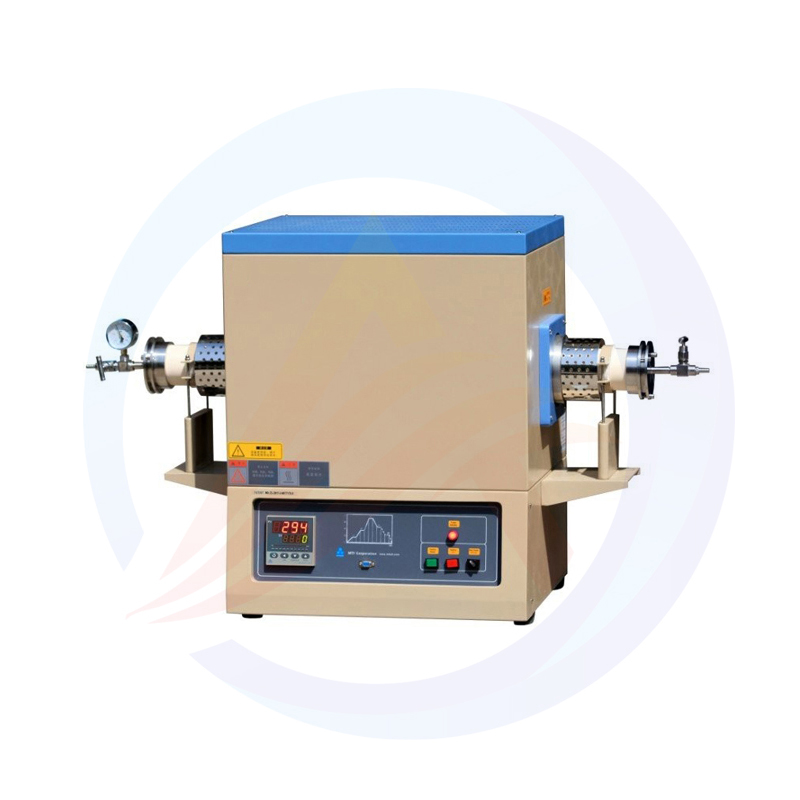

Sodium-ion layered transition metal oxides are usually expressed as NaxMO2, where M is a transition metal element such as Mn, Ni, Cu, Fe, Co, etc. The study shows that the arrangement of NaxMO2 can be divided into O-type and P-type, and its structure diagram is as follows. The layered structure of this transition metal oxide not only provides channels for sodium ion embedding and deembedding, but also enhances the stability of the overall structure by utilizing the MO6 octahedral structure. Therefore, the material has excellent electrochemical performance and is currently the mainstream positive electrode material for sodium ion batteries. At the same time, the material has a high correlation with the electrolyte technology.

The cupric oxide cathode material CuFeo2 is suitable for sodium-ion batteries at room temperature. Based on copper, the material exhibits a reversible capacity of 220 mAh/g, and its electrochemical reaction mechanism mainly involves the REDOX reaction of Cu2+/Cu+. The working voltage of CuFeo2 can reach 2.4V, and has good cycle stability. This material has the characteristics of low cost, excellent performance and environmental friendliness, and has shown a certain prospect.

Negative electrode material - carbon-based material

There are many kinds of anode materials for sodium ion batteries, including carbon-based materials, titanium-based materials, alloy materials and organic materials. Among them, carbon-based materials are regarded as the most promising candidate materials due to their availability and low cost. Carbon-based materials are mainly divided into two categories: crystalline carbon and amorphous carbon, crystalline carbon mainly natural graphite and artificial graphite, which are the main negative electrode materials for lithium-ion batteries. However, when graphite is used as the negative electrode of the sodium ion battery, the embedding of sodium ions cannot be achieved, resulting in too low specific capacity to meet the needs of practical applications. Amorphous carbon materials mainly include hard carbon and soft carbon. Hard carbon shows high initial discharge capacity, good rate performance and structural stability, and has good electrochemical performance advantages, and is currently the first choice of negative electrode materials. Although soft carbon has low cost, high electrochemical activity, and can provide a high reversible capacity, its specific capacity is low, and the volume expansion problem needs to be solved. Due to the comprehensive advantages of abundant resources, low cost, structural diversity and excellent electrochemical performance, amorphous carbon materials are generally considered as one of the most promising anode materials for sodium ion batteries in the industry.

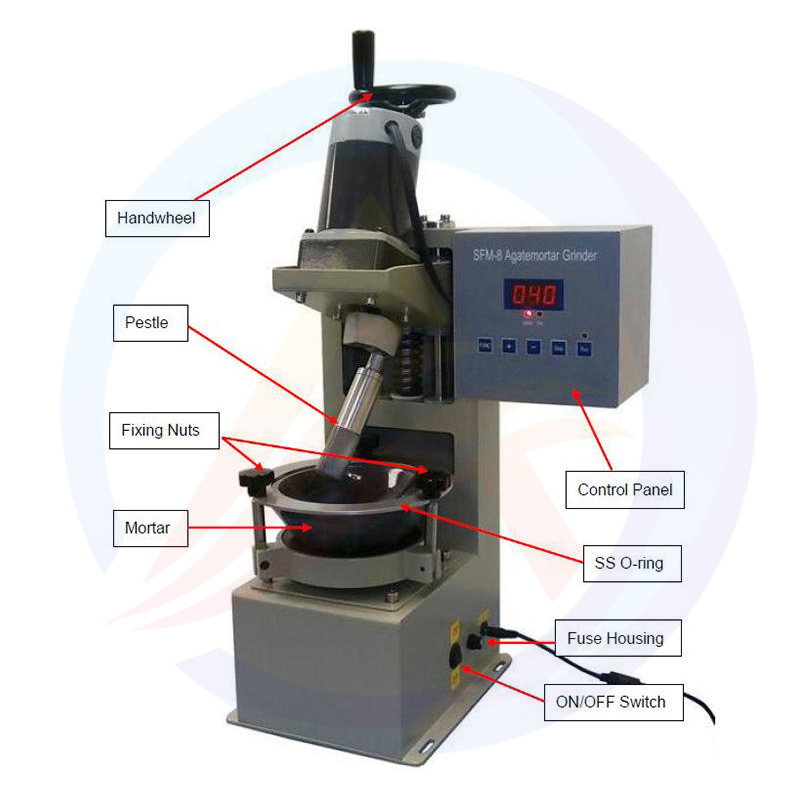

Hard carbon can be prepared by a variety of precursor systems, and the difference of precursor will affect the microscopic morphology and defect degree of the final hard carbon, and then affect its electrochemical performance.

Electrolyte

In addition to positive and negative electrode materials, electrolyte is also an indispensable reaction medium. The sodium ion battery electrolyte mainly consists of three parts: sodium salt, solvent and additive. Sodium salt plays a key role in the electrolyte, which directly affects the charge-discharge performance and life of the battery. In order to maintain the stable operation of the battery, the sodium salt must have good electrochemical stability and cannot have side reactions with the electrode material. Ideally, sodium salts should be able to dissolve completely in the selected solvent system and generate electrochemically active sodium ions, so that they can migrate freely in the electrolyte and quickly reach the electrode surface for reversible reactions. In addition, high-quality sodium salt should also minimize side reactions with other battery components to improve the safety of the battery.

Future development prospect

Although in terms of cost, sodium-ion batteries have advantages compared to lithium-ion batteries, there are obvious deficiencies in energy density, and they are currently mainly carried on small mini-vehicles with low battery life requirements and high cost sensitivity. With the explosive development of new energy vehicles in recent years, lithium-ion resources are increasingly scarce, and it can be predicted that sodium-ion battery technology will usher in a golden development period. With the continuous breakthrough in materials, electrochemical performance, safety and other aspects, the industrialization of sodium-ion batteries is also accelerating, in addition to the current small and micro electric vehicles, the future is also expected to be carried in plug-in hybrid vehicles, the vehicle price will be further pulled down.