Preparation and assembly of button batteries

1. Lithium-ion button battery components:

1.1 coin cell cases

The following is the CR2032 coin cell battery shell, the positive shell is larger, the negative shell has a network structure on the surface and is small, so the general assembly process starts from the negative shell.

1.2 Pole Plate

The preparation process of electrode sheet has an important influence on whether the electrochemical properties can be fully utilized.

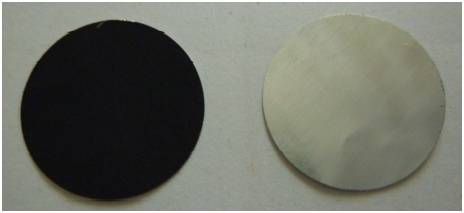

The following figure shows the electrode plate prepared by the positive electrode material.

The preparation process of the positive and negative electrode sheets is the same, the difference is that the positive electrode is coated on the aluminum foil, and the negative electrode is coated on the copper foil, which is why?

First of all, the electrical conductivity of both is relatively good, the texture is relatively soft, and the price is relatively low.

Secondly, aluminum itself is relatively active, at low potential, aluminum will appear lithium, lithium aluminum alloy, not as a negative collector. If aluminum foil is used as a negative collector, aluminum will form an alloy with lithium, and then powder, seriously affecting the life and performance of the battery.

Finally, copper is easy to oxidize at high potential and is not suitable as a positive collector. The oxide layer on the surface of copper is a semiconductor, and the electron is conductive. When the oxide layer is too thick, the impedance will increase. At the same time, lithium will not form lithium alloy with the same site.

What kind of pole film is good pole film?

These aspects should be satisfied:

1) The slurry coating is uniform, no obvious thickness is not uniform, especially thin places can even observe bright aluminum foil;

2) The pole piece remains intact and round without damage, and there are no burrs around it as far as possible;

3) There is no particulate matter in the coating area and no obvious powder-dropping phenomenon.

1.3 Separator

The separator used in the laboratory is generally Celgard2400 or other products of the Celgard series, which is stamped into a small round sheet and used after the diameter is slightly larger than the positive and negative electrode sheet.

What is the function of the separator?

Simply put, if there is no separator, the positive and negative poles are in direct contact, that is, a short circuit will occur, which is why some batteries should inhibit the generation of lithium dendrites, that is, to prevent it from punctures the separator, causing a local short circuit, and resulting in safety accidents.

1.4 Lithium metal chips

The diameter of the negative plate is slightly smaller than the diameter of the negative shell. The diameter of the lithium metal chip of CR2032 is 15.8mm, and the corresponding positive plate is also 15.8mm.

It is worth noting that the lithium chip is relatively soft and easy to deform, so the deformed lithium chip can be pressed flat with a positive shell (because it is relatively large) before installing the battery. Moreover, lithium metal is very easy to oxidize and deteriorate in the air, and it is easy to explode in the case of water, so the purchased lithium metal chip needs to be opened in the glove box, and pay attention to not damaging the glove when opening.

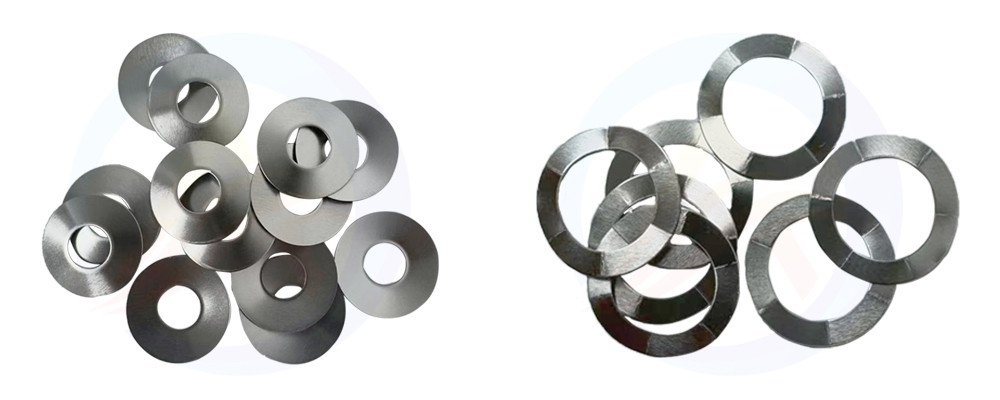

1.5 Spacer

The spacer is a circular aluminum sheet, the diameter is the same as the size of the lithium chips, and in the experiment, different specifications and thicknesses can be purchased according to demand.

Note: spacer, positive and negative coin cell cases and other components should be repeatedly cleaned with alcohol ultrasonically before use, and then dried in an air drying oven.

1.6 Spring

Spring mainly plays the role of supporting the battery, if there is no spring, the battery will be pressed very flat in the step of pressing the battery, and the internal components may be crushed. Spring is only added on the negative side, but if both the positive and negative terminals are added with spring, the buckle can not be closed during the voltage battery step, resulting in the electrolyte contacting with the air, and the experiment fails.

1.7 Electrolyte

Different materials generally correspond to different electrolytes.

2. Assembly of coin cell battery

2.1 Preparation of positive electrode plate

The preparation of pole sheet is mainly divided into two steps:

1) preparation of slurry;

2) Coating, drying, pressing and other steps.

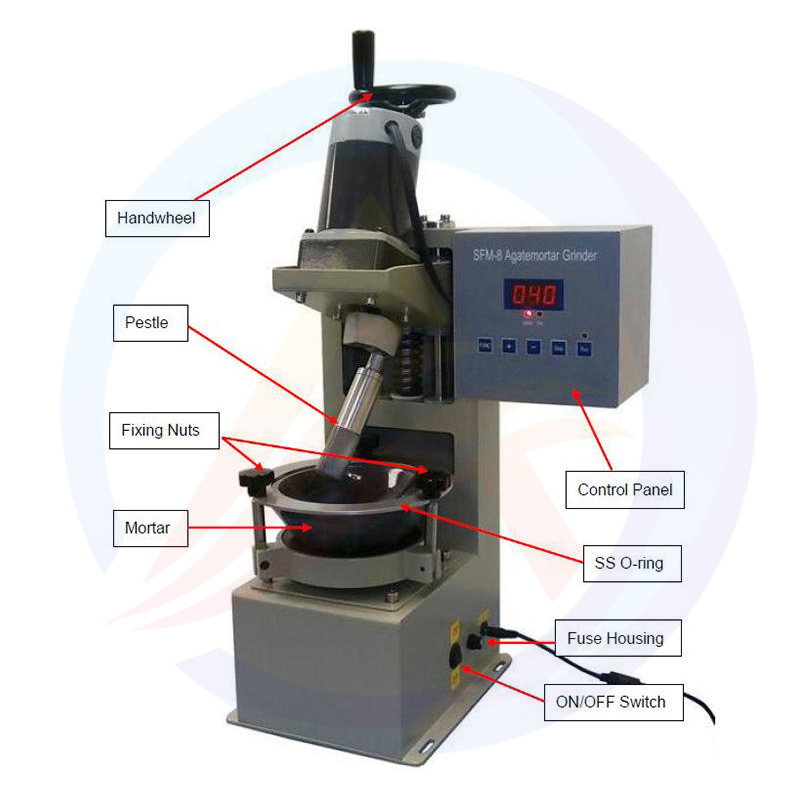

2.1.1 Preparation of slurry

The slurry is composed of solvent, cathode material, conductive agent and binder.

The mass ratio of positive electrode material: conductive agent: binder is 80:10:10.

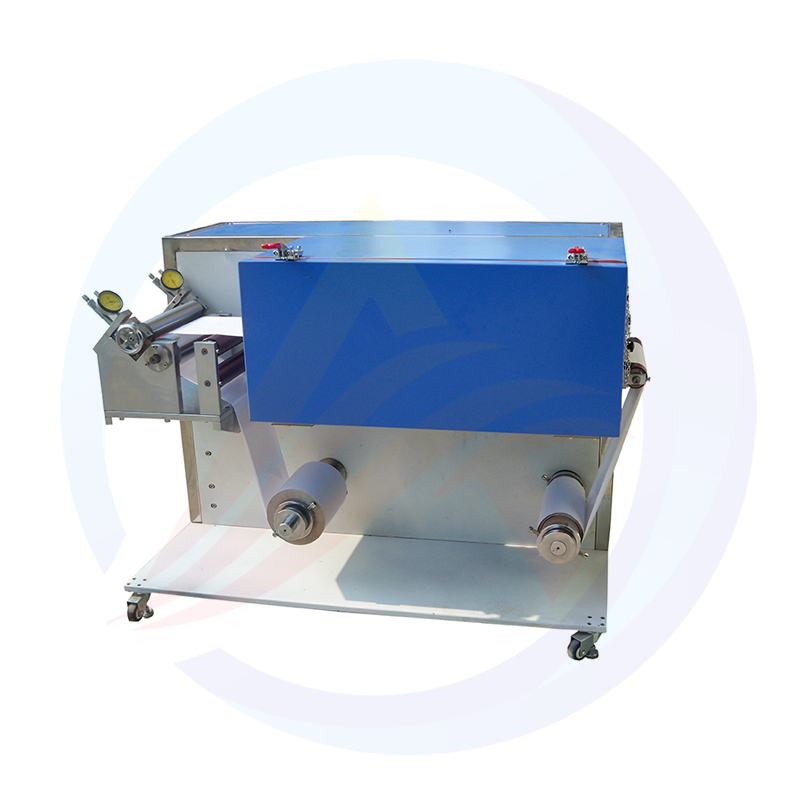

2.1.2 Coating of plate

Generally, a scraper and a casting coating machine are used for coating, and the positive electrode material is coated on the aluminum foil and the negative electrode is coated on the copper foil. Students who do not have a coating machine can use a glass plate and a scraper for coating. The coating process is relatively simple, but the following points need to be noted

1) The aluminum foil needs to be flat and the folds should be reduced as much as possible;

2) Before coating, carefully clean aluminum foil and coating machine platform with alcohol and absorbent cotton;

3) The absorbent cotton should be carefully cleaned with toilet paper after cleaning, one to remove the cotton wool that may exist and two to do not scratch the aluminum foil.

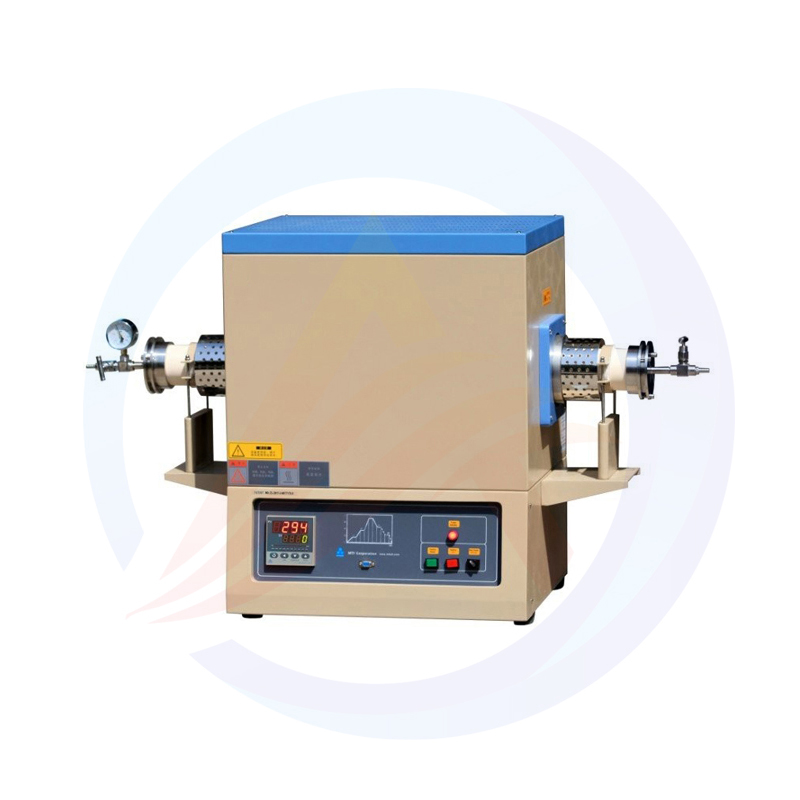

2.1.3 Drying and pressing of pole sheet

The purpose of drying is to remove a large amount of solvent and water in the slurry, so it must go through two steps of blast drying and vacuum drying. The specific temperature and time of each step are reported differently in different jobs.

2.1.4 Tablet pressing

After coating, the dry composite coating is relatively loose. If used directly, it is easy to fall off and damage after being soaked by electrolyte. Rolling machines or tablet presses can be used for tablet processing. Generally, roller machines can press the positive electrode coating to 15-60 μ m. The tablet press can be pressed at a pressure of about 80-120kg/cm2. The stability, firmness and electrochemical properties of the electrode after pressing were improved, and the test performance was better than that of the sample without pressing.

There are two main purposes for tablet pressing:

First, in order to eliminate burrs, so that the surface is smooth and flat, to prevent the battery when the burrs Pierce the diaphragm caused by short circuit;

The second is to enhance the strength of the pole plate and reduce the ohmic impedance. Too much pressure will cause the pole to curl, which is not conducive to battery assembly, and too little pressure can not play the role of pressing.

2.1 Assembly of coin cell battery

2.1.1 Necessary Items:

Glove box: tablet press (preferably with digital display), 2 tweezers (at least one is plastic tweezers), 1 medicine spoon, electrolyte, lithium tablets, grinding glass bottles (with plastic head dropper), syringes, dry paper towels and other cleaning supplies;

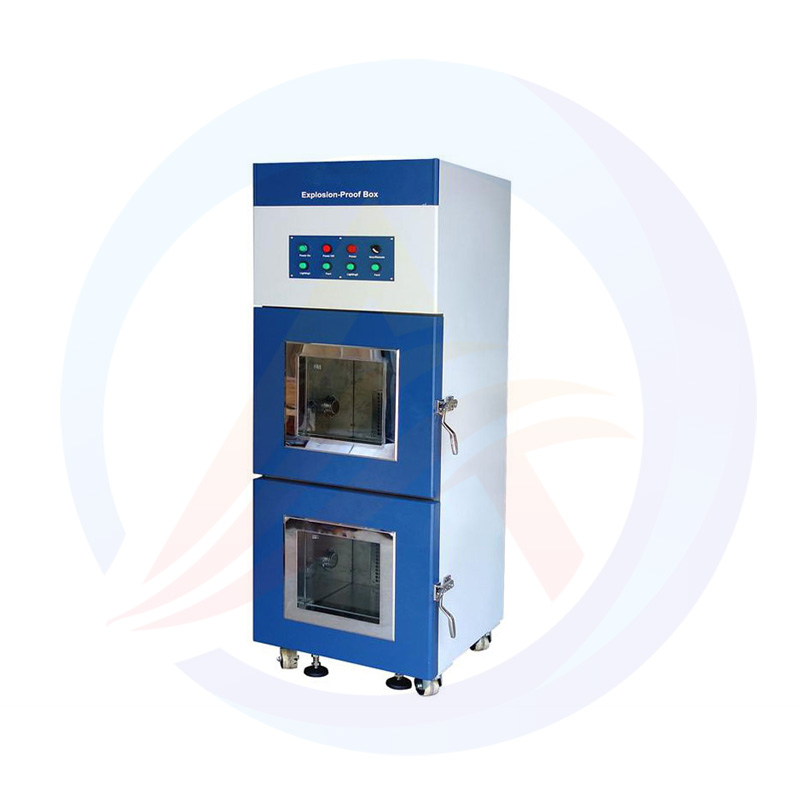

Outside the glove box: coin cell cases, collector, spring plate (or nickel foam ), positive plate, separator plate;

Note: The battery assembly parts should be vacuum-dried for about 4 hours before being placed in the glove box, and the temperature should not be too high, which can be set at 60-80 ° C. Larger capacity glove boxes can store these battery parts in advance and are cleaner. After the raw material enters the door of the inlet box, exhaust-intake operation shall be carried out in strict accordance with the operating procedures, at least three times. It is recommended to place a small operating table in the glove box to prevent reagents from corroding the glove box. The electrolyte corrodes the gloves and the inner wall of the glove box, and should be avoided as much as possible.

2.1.2 Determine the oxygen content of water

The general glove box has a digital display detector for water oxygen content, and the water oxygen content of Brian's glove box can be controlled at less than 0.05PPM, but the standards of different glove boxes are not the same. The battery assembly process is carried out in a glove box that has been strictly exhaust-intake operation, strictly isolated from any possible oxidation, moisture and other interference. If the water oxygen content of the glove box is consistently high, the glove should be checked for damage or the glove box should be regenerated.

2.1.3 Assembly process

There are two main assembly sequence of coin cell batteries, the laboratory is generally used to start from the negative coin cell case, but it can also start from the positive coin cell case.

1) The opening of the positive coin cell case faces upward and is placed flat on the glass plate

2) Place the spacer and the positive plate into the positive coin cell case with tweezers, and the positive plate is located in the center

3) Absorb the electrolyte with a plastic head dropper or syringe and infiltrate the surface of the positive electrode plate

4) Clamp the separator and cover the positive plate

5) Use the eyedropper/syringe again to absorb the electrolyte and wet the surface of the separator.

6) Take the lithium chip and place it in the middle of the separator

7) Clamp the spacer and place it on the lithium chip, strictly aligned

8) Grab the spring and place it on the spacer, strictly aligned

9) Tweezers clamp the negative coin cell case cover