2、the importance of lithium battery planetary ball mill

3、the role of the planetary ball mill in the field of lithium batteries

4、lithium battery star ball mill operation points

1、what is the star ball mill?

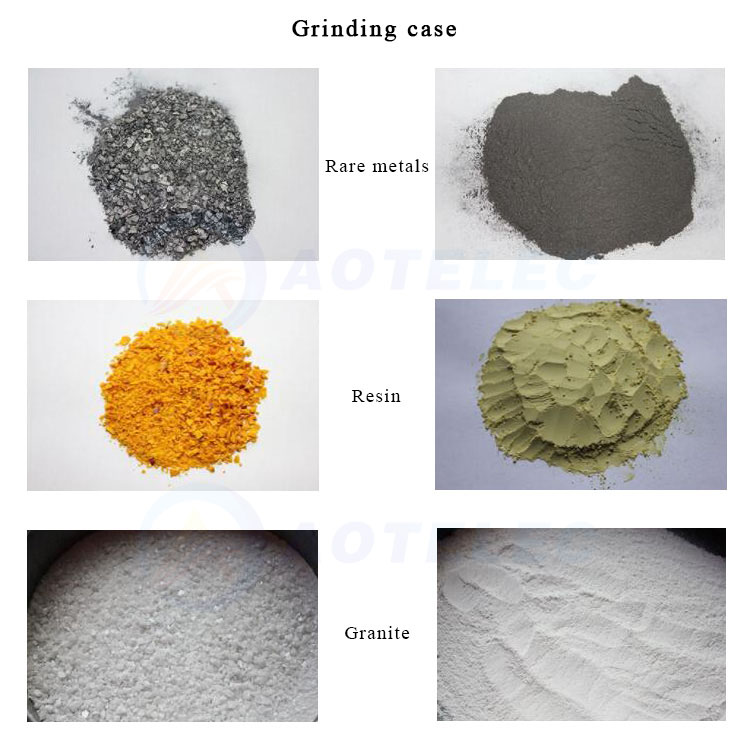

Planetary ball mill is a necessary device for mixing, fine grinding, sample preparation, nanomaterial dispersion, new product development and small batch production of high-tech materials. The product has small size, full function and high efficiency. It is the ideal equipment for scientific research units, colleges and universities, and enterprise laboratories to obtain microparticle research samples (four samples can be obtained at the same time in each experiment). The vacuum ball mill can be used to grind samples in vacuum state. Widely used in geology, minerals, metallurgy, electronics, building materials, ceramics, chemical industry, light industry, environmental protection and other departments, such as: Electronic ceramics, structural ceramics, magnetic materials, lithium cobaltate, lithium manganate, catalyst, phosphor, long persistence luminescent powder, rare earth polishing powder, electronic glass powder, fuel cell, ceramic capacitor, oxygen Zinc varistors, piezoelectric ceramics, nanomaterials, wafer ceramic capacitors, MLCC, Thermistor (PTC, NTC), ZnO varistors, arrester valves, strontium titanate ring varistors, ceramic filters, dielectric ceramics, piezoelectric energy transducers, piezoelectric transformers, chip resistors, thick film circuits, pyropotentiometers, Alumina ceramics, zirconia ceramics, Phosphor, zinc oxide powder, cobalt oxide powder, Ni-Zn ferrite, Mn-Zn ferrite and other products in the production field and other industries.

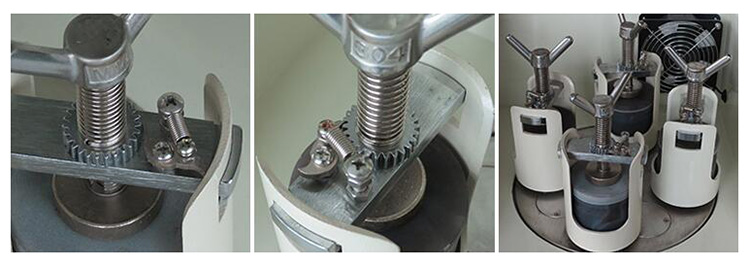

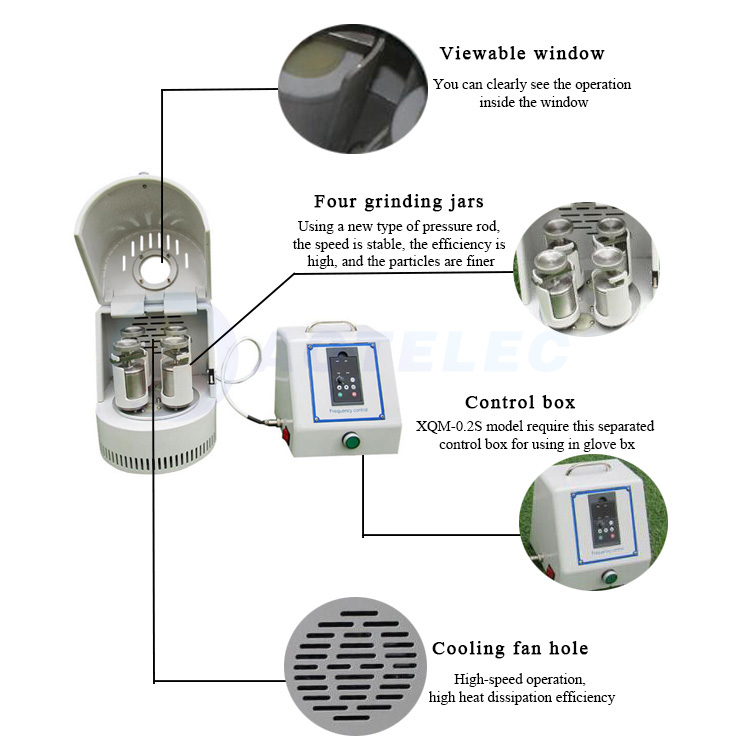

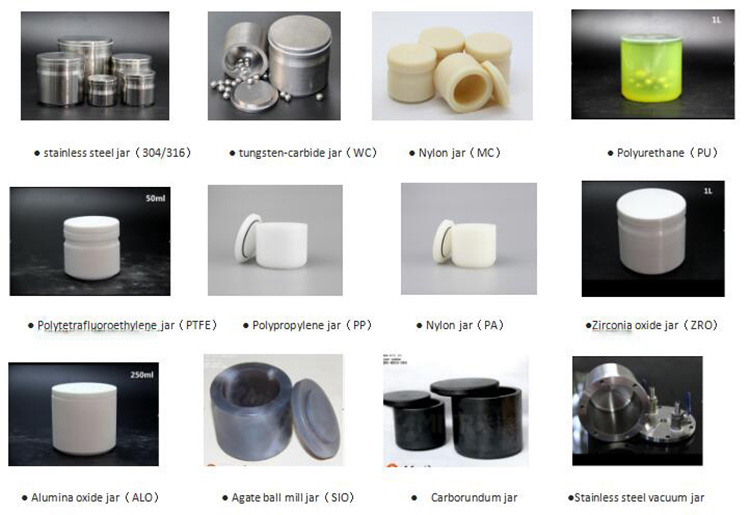

Planetaryball mill machine is designed for crushing, grinding, dispersing metal, non-metal, organic, Chinese herbal powder, especially suitable for laboratory research use, its working principle is to use abrasive and test material in the grinding tank rolling at high speed, strong shear, impact, rolling to achieve the purpose of crushing, grinding, dispersing, emulsifying materials. Planetary ball mill is equipped with four ball mill tanks on the same turntable, when the turntable rotates, the ball mill tank rotates around the axis of the turntable while rotating around its own axis, making planetary movement. The grinding balls in the tank collide with each other in high-speed motion, grinding and mixing samples. The product can be ground and mixed by dry and wet methods with different particle sizes and materials, and the minimum particle size of the grinding product can reach 0.1 micron. It can well achieve various process parameter requirements, and because of its advantages of small batch, low power consumption and low price, it is the preferred equipment for schools, research units and companies to conduct research on crushing technology, new materials and coatings.

2、the importance of lithium battery planetary ball mill

(1) Efficient grinding and mixing

Grinding efficiency: The planetary ball mill, through its unique planetary operation mode, is able to efficiently grind the raw material powder to the desired particle size and shape. This efficient grinding capability helps to improve the activity and electrochemical properties of the material.

mixing uniformity: In the grinding process, the ball mill can continuously mix various raw materials to ensure the uniform distribution of positive electrode materials. This is essential to improve battery stability and cycle life.

(2) Improve material properties

Surface activity: The ball mill produces a large number of surface active sites during the grinding process, which can enhance the interaction between the material and the electrolyte, thereby improving the energy density and power density of the battery.

Structure control: By adjusting the parameters of the ball mill, such as the type of abrasive, grinding time and speed, the precise control of the material particle size, structure and performance can be achieved to meet the needs of different application scenarios.

(3)Promoting technological innovation

Research and development of new electrode materials: The ball mill provides strong support for the research of new electrode materials. Through precision processing and mixing, more efficient and stable electrode materials can be created, thus promoting the continuous progress of battery technology.

Nanomaterials preparation: With the development of battery technology, the demand for nanomaterials is increasing. The star ball mill can fine the various components in the battery material to the nanometer level, which helps to improve the key indicators such as the conductivity and energy storage performance of the battery material.

(4) Strong adaptability

Wide application fields: Star ball mill is not only suitable for the production of lithium battery materials, but also widely used in geology, minerals, metallurgy, electronics, building materials, ceramics, chemical industry, light industry, medicine, environmental protection and other departments, showing its strong adaptability and wide application prospects.

A variety of working modes: The ball mill can be used in the form of wet method and dry method for ultrafine grinding or mixing of materials to meet the needs of different materials and processes.

(5) Convenient operation and maintenance

Easy operation: The star ball mill usually has the characteristics of beautiful novel, compact structure and easy operation, which can improve production efficiency and user experience.

Simple maintenance: With the continuous progress of technology, modern ball mills pay more attention to maintainability in design and manufacturing, reducing maintenance costs and time.

Easy operation: The star ball mill usually has the characteristics of beautiful novel, compact structure and easy operation, which can improve production efficiency and user experience.

Simple maintenance: With the continuous progress of technology, modern ball mills pay more attention to maintainability in design and manufacturing, reducing maintenance costs and time.

3、the role of the planetary ball mill in the field of lithium batteries

(1) Material preparation

Raw material grinding: One of the core materials of lithium batteries is the positive electrode material, whose performance directly affects the performance and stability of the battery. The star ball mill can use the characteristics of three-dimensional swing and high-speed rotation to grind the raw material powder efficiently, so that it can reach the desired particle size and shape. This fine grinding process helps to improve the activity and electrochemical properties of the material.

Uniform mixing: Star ball mill in the grinding process, through the grinding ball and sample bottle samples three-dimensional mixing, to ensure that the various components of the positive material can be evenly distributed. This uniformity is essential to improve battery stability and cycle life.

(2) Performance improvement

Surface activity enhancement: Star ball mill in the grinding process will produce a large number of surface active sites, these sites can significantly improve the electrochemical activity of the material, enhance the interaction between the material and the electrolyte, thereby improving the energy density and power density of the battery.

Nanomaterial preparation: With the increasing application of nanotechnology in the field of lithium batteries, the planetary ball mill can prepare nanoscale battery materials. Nanomaterials have a higher specific surface area and better electrochemical performance, which helps to improve the overall performance of the battery.

(3) Process optimization

Controllability and adjustability: Star ball mill has good controllability and adjustability, by adjusting the type of abrasive, grinding time and speed and other parameters, you can achieve accurate control of material particle size, structure and performance. This flexibility allows the planetary ball mill to adapt to the needs of different lithium battery material preparation processes.

Energy saving and high efficiency: Compared with traditional ball mills, star ball mills perform well in terms of crushing efficiency and energy consumption. Its high efficiency and energy saving characteristics help to reduce the cost of lithium battery material preparation process and improve production efficiency.

(4) Widely used

Positive electrode materials: The star ball mill plays a key role in the preparation of positive electrode materials for lithium batteries, such as nickel-cobalt-manganese ternary materials, lithium iron phosphate, etc.

Negative material: Although the preparation of negative material is relatively simple, the planetary ball mill can also be used to optimize the particle size and distribution of negative material to improve battery performance.

Other materials: In the preparation process of key materials such as electrolytes and diaphragms of lithium batteries, the planetary ball mill can also provide strong support.

4、lithium battery star ball mill operation points

The main points of operation of lithium battery ball mill mainly include: ensure that the equipment is placed smoothly, and carry out idling inspection before use; Add samples and grinding media correctly, pay attention to the ratio of pellets and reserve grinding space; Set the appropriate grinding time and speed; Keep the equipment dry during operation, avoid wet hands operation; Monitor the temperature of the ball mill tank to prevent overheating; Power off and cool the ball mill in time after the end; Finally, clean the ball mill tank and ball thoroughly. Following these points ensures efficient grinding of lithium battery materials and stable operation of equipment.