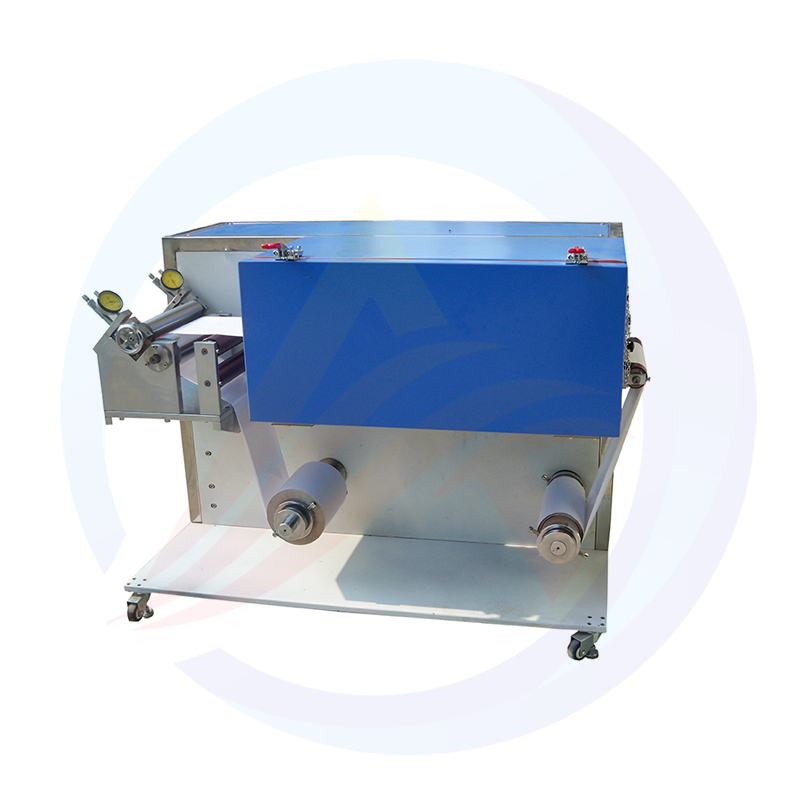

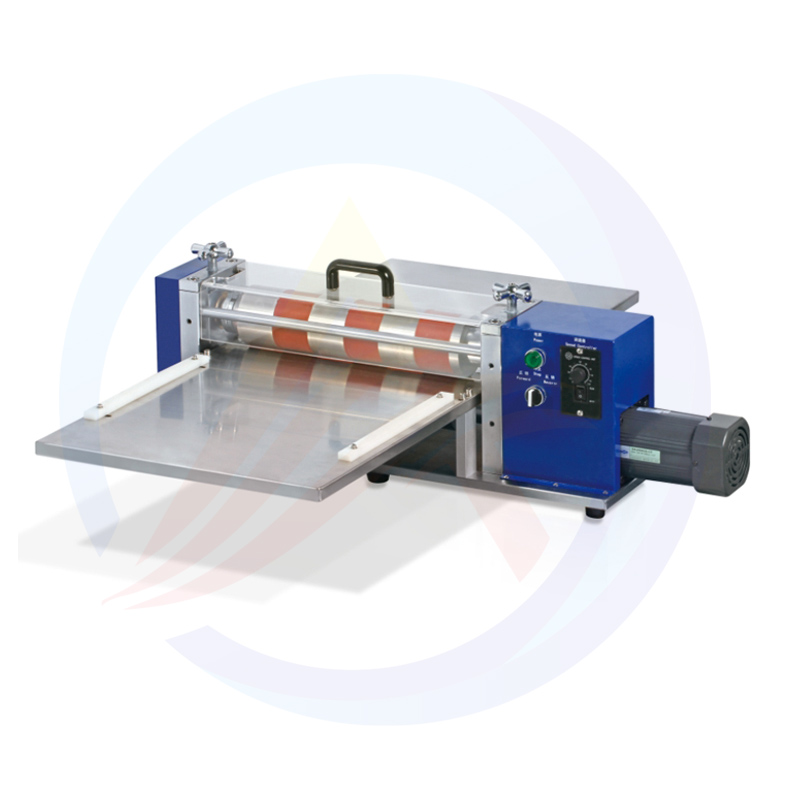

Electrode Slitting Machine for Lithium Battery

The Electrode Slitting Machine for Lithium Battery is a crucial piece of equipment in the production process of lithium-ion batteries. It specializes in cutting electrode materials, such as cathode and anode foils (typically copper and aluminum), into specific dimensions and shapes required for battery assembly.

1. Key Functions

The primary function of this machine is to precisely slit continuous rolls of electrode materials into thin strips or sheets that meet the dimensional and quality standards set by battery manufacturers. This process ensures that the electrodes fit seamlessly into the battery structure, contributing to the overall performance and reliability of the final product.

2. Operating Principles

The Electrode Slitting Machine for Lithium Battery operates based on a series of precise and coordinated steps to cut electrode materials into specific dimensions required for battery assembly. Here's a detailed explanation of its working principle in English:

2.1 Material Feeding:

The continuous roll of electrode material (such as copper or aluminum foil) is fed into the machine's input section. A sophisticated feeding mechanism, often comprising rollers or conveyor belts, ensures smooth and stable material delivery to the cutting area.

2.2 Positioning & Alignment:

Prior to cutting, the material is precisely positioned and aligned using mechanical or electronic sensors. This step is crucial to ensure accurate cutting at the desired locations. Advanced machines may incorporate automatic edge-guiding systems to continuously adjust the material's position during the cutting process, preventing deviations.

2.3 Cutting Operation:

Once the material is properly positioned, the cutting system engages. This typically involves a set of sharp blades (e.g., circular, flat, or rotary blades) that rotate or move linearly at high speeds to make clean cuts. The machine's control system precisely regulates the cutting parameters (width, depth, speed, etc.) based on preset values to achieve the desired outcome.

2.4 Waste Handling:

The scrap material generated during the cutting process (e.g., excess edges) is efficiently collected and disposed of. Some machines are equipped with waste management systems that automatically convey the scrap to designated containers for easy disposal or recycling.

2.5 Product Collection & Organization:

The cut electrode strips or sheets are collected and organized for further processing or assembly. This may involve stacking, rolling, or conveying the product to the next stage of production. Some machines incorporate automatic stacking or winding mechanisms to streamline this process.

2.6 Quality Control & Inspection:

Throughout the cutting process, the machine performs quality control checks to ensure the accuracy and consistency of the cuts. This may include monitoring the cutting dimensions, edge quality, and the presence of burrs or imperfections. Advanced machines may utilize online inspection systems that continuously monitor the cutting process and automatically adjust parameters to maintain quality standards.

In summary, the Electrode Slitting Machine for Lithium Battery relies on precise material handling, cutting technology, and quality control mechanisms to efficiently produce high-quality electrode materials for lithium-ion battery production. The process is highly automated and designed to meet the demanding requirements of the battery manufacturing industry.

3. Key Features

3.1 High Precision: Capable of achieving extremely precise cuts, ensuring electrode materials meet strict tolerance requirements.

3.2 Efficiency: Designed for continuous, high-speed operation, boosting production throughput.

3.3 Stability: Robust construction and stable operation ensure consistent cutting quality over extended periods.

3.4 Ease of Maintenance: Modular design simplifies routine maintenance and component replacement tasks.

4. Applications

The Electrode Slitting Machine for Lithium Battery has a specific and vital purpose in the production of lithium-ion batteries. Its primary function is to cut continuous rolls of electrode materials, such as copper or aluminum foil, into precise strips or sheets of predetermined widths and lengths. These electrode materials are then used as the current collectors in the anode and cathode of lithium-ion batteries.

Here are the key uses and benefits of this machine:

1)Precision Cutting: The machine ensures that the electrode materials are cut to exact specifications, which is crucial for maintaining battery performance and ensuring consistent quality across production runs.

2)Efficiency: By automating the cutting process, the machine significantly increases production efficiency compared to manual cutting methods. This not only reduces labor costs but also speeds up the overall battery manufacturing process.

3)Waste Reduction: The machine minimizes waste by precisely cutting only the necessary material, leaving minimal scrap. This not only saves on material costs but also reduces the environmental impact of battery production.

4)Compatibility with Automation: The Electrode Slitting Machine is often integrated into larger automated production lines, allowing for seamless transfer of materials between different stages of the battery manufacturing process.

5)Scalability: The machine can be scaled up or down to meet the production demands of different manufacturers. Whether producing small batches for research and development or large-scale commercial production, the machine can be configured to suit the specific needs of the operation.

6)Quality Control: Many modern Electrode Slitting Machines incorporate advanced quality control features, such as automatic inspection systems, to ensure that every cut meets strict quality standards. This helps to maintain the reputation and reliability of the battery manufacturer.

In summary, the Electrode Slitting Machine for Lithium Battery is an essential tool in the production of high-quality lithium-ion batteries. Its precision, efficiency, and compatibility with automation make it a valuable asset for any battery manufacturer looking to optimize their production process and maintain consistent quality standards.