Operation Guide for Lithium Battery Coating Machine

This operation guide is designed to provide operators with detailed steps, precautions, and safety regulations for the lithium battery coating machine. The purpose is to ensure the smooth operation of the equipment, improve production efficiency, and guarantee product quality.

Table of contents

II. Components of Lithium Battery Coating Machine Equipment

III. Pre-operation Preparation

I.Equipment Overview

The lithium battery coating machine is a key equipment in the production process of lithium batteries. It is mainly used to coat active materials uniformly onto electrode materials to form electrode sheets. The equipment consists of a coating system, a transportation system, a control system, and other components.

II. Components of Lithium Battery Coating Machine Equipment

The lithium battery coater machine equipment comprises several essential components that work together to ensure efficient and precise coating of battery electrodes. Here is a breakdown of the main components:

1. Coating System:

Coating head or nozzle: Responsible for evenly dispensing the coating material onto the electrode surface.

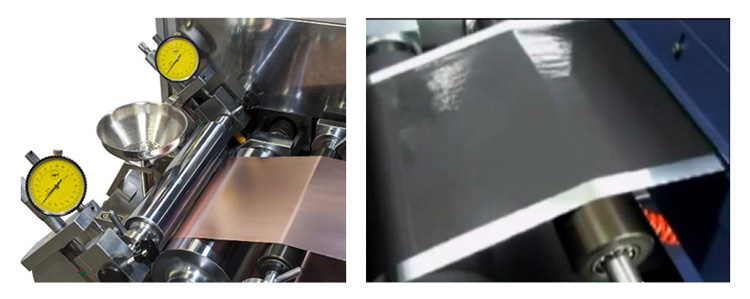

Coating roller or blade: Used to adjust and control the coating thickness and uniformity. The roller wraps the coating material onto the electrode, while the blade removes excess material.

2. Material Supply System:

Material tank or reservoir: Stores the coating material and ensures a continuous supply to the coating head.

Pump and piping: Transports the coating material from the tank to the coating head, maintaining the desired flow rate and pressure.

3. Substrate Transportation System:

Conveyor belt or rollers: Carries the electrode material (substrate) through the coating zone at a controlled speed.

Drive mechanism: Provides the power to move the conveyor belt or rollers.

4. Drying System:

Heating unit: Heats the coated electrode to accelerate the drying and curing process of the coating material.

Ventilation system: Removes harmful gases and solvent vapors generated during the coating and drying process.

5. Control System:

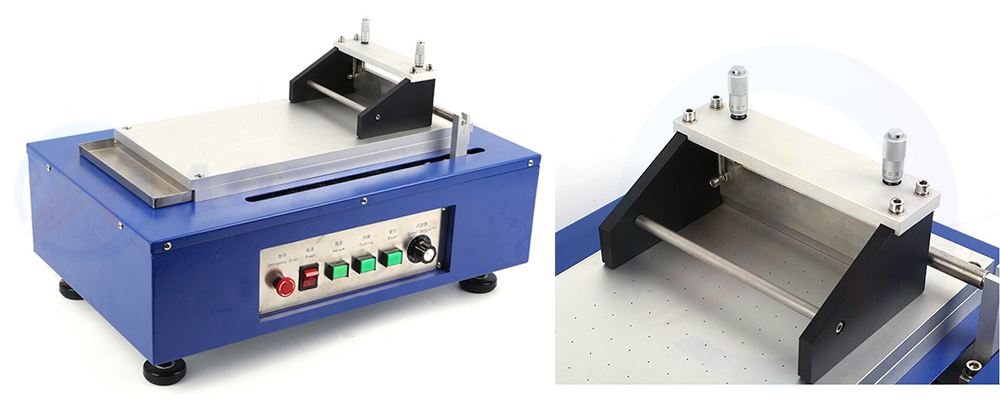

Electrical control panel: Houses the electrical components and control modules that regulate the various functions and parameters of the coating machine.

Human-machine interface (HMI): Displays the operational status, parameter settings, and operational prompts of the coating machine, allowing operators to monitor and adjust the machine's operation.

Sensors and detectors: Continuously monitor critical parameters such as coating speed, coating thickness, and temperature, providing feedback to the control system for adjustment.

6. Safety and Protection System:

Emergency stop buttons: Allows operators to quickly halt the machine in case of an emergency.

Guards and safety covers: Protect operators from contact with moving parts or hazardous areas.

Warning lights and alarms: Provide visual and auditory indications of potential hazards or faults.

7. Cleaning and Maintenance System:

Cleaning nozzles or brushes: Used to clean the coating head and other critical components to maintain their performance.

Lubrication system: Ensures smooth and efficient operation of moving parts by supplying lubricant.

The above components work in unison to ensure precise, efficient, and safe coating of lithium battery electrodes. The specific configuration and components of the lithium battery coating machine may vary depending on the manufacturer and model.

III. Pre-operation Preparation

Check if all parts of the equipment are intact and free from looseness or damage.

Clean the equipment surface and working area to ensure there are no impurities, dust, or pollutants.

Prepare the required materials such as electrode materials and coating solution, and ensure their quality meets the requirements.

Turn on the power supply of the equipment and check if the control system is working properly.

IV. Operation Steps

Place the electrode material at the starting position of the transportation system and secure it.

Set the coating parameters in the control system according to the product requirements, such as coating speed, coating thickness, and coating width.

Start the transportation system to make the electrode material pass through the coating area at the set speed.

Start the coating system and spray the coating solution evenly onto the surface of the electrode material through the nozzle.

Monitor the coating process, observe the coating effect, and adjust the parameters in time if there is any abnormality.

After the electrode material is coated, turn off the coating system and transportation system.

Take out the coated electrode material for subsequent processing or quality inspection.

V. Precautions

During operation, strictly follow the equipment manual and this operation guide to avoid misoperation that may cause equipment damage or product quality issues.

Closely monitor the coating effect during the coating process and adjust the parameters in time to ensure uniform coating and consistent thickness.

Replace or add the coating solution regularly to ensure stable coating quality. When replacing the coating solution, turn off the coating system and drain the old coating solution before adding new one.

During equipment operation, if any abnormality is found (such as abnormal noise or vibration), immediately stop the machine for inspection and troubleshooting.

Regularly perform maintenance and upkeep of the equipment, including cleaning, lubrication, and tightening, to ensure its normal operation and extend its service life.

VI. Safety Regulations

Operators should wear protective clothing, gloves, and other protective equipment that meet safety requirements to ensure personal safety.

It is prohibited to perform cleaning, maintenance, or other operations during equipment operation to prevent accidents.

It is prohibited to place non-designated items on the equipment or in the working area to avoid affecting the normal operation of the equipment or causing safety hazards.

Set up clear safety warning signs and isolation facilities around the equipment to prevent non-operators from entering the working area.

Regularly conduct safety training and education for operators to improve their safety awareness and operational skills.