Battery sealing machine Comprehensive Guide: From beginner to master

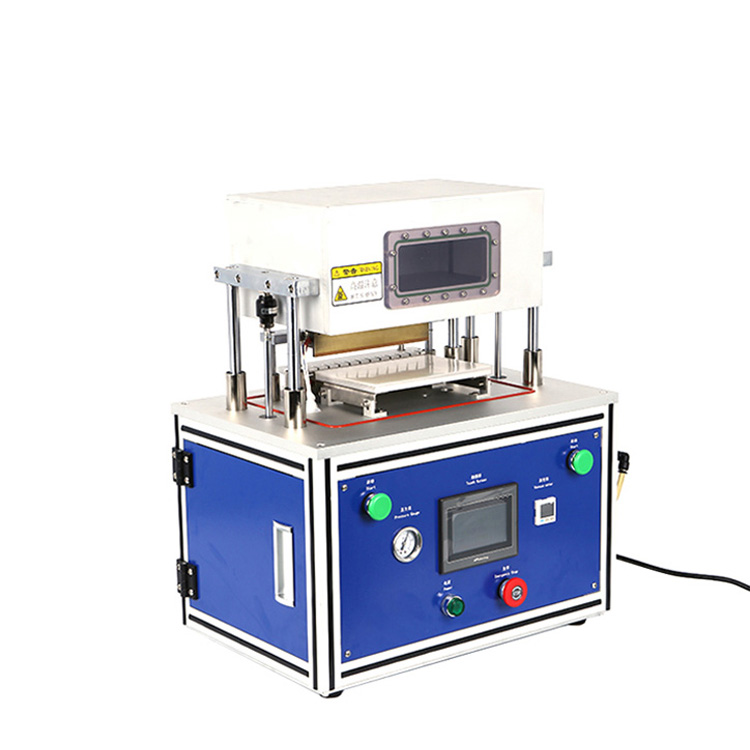

1、brief introduction to the importance of the battery sealing machine

2、basic knowledge of battery sealing machine

3、the battery sealing machine operation steps detailed explanation

4、advanced operation skills and troubleshooting

brief introduction to the importance of the battery sealing machine

1, Ensure battery tightness: The main function of the battery sealing machine is to ensure the tightness between the battery housing and the internal components through precise operation. Good sealing can prevent internal liquid leakage, gas escape and the intrusion of external impurities, so as to ensure the safety and stability of the battery during use.

2, improve production efficiency: Modern battery sealing machine using advanced automation technology, can achieve high-speed, accurate sealing operation. This greatly improves the production efficiency of batteries, reduces production costs, and meets the growing demand for battery products in the market.

3, ensure product quality: the performance of the battery sealing machine directly affects the quality of the battery product. The high-quality sealing machine can ensure that the battery is not damaged during the packaging process, and avoid the occurrence of internal short circuit, open circuit and other quality problems. At the same time, it can also ensure the appearance of the battery clean and beautiful, improve the market competitiveness of the product.

basic knowledge of battery sealing machine

1, the basic principle of the battery sealing machine

(1) Heating sealing technology:

The battery sealer heats the sealing area through the built-in heating element (such as electric heating wire, heating plate, etc.).

When the sealing area reaches a certain temperature, the material (such as plastic, metal, etc.) will soften or melt, forming a plastic state.

In this state, through mechanical pressure or vacuum adsorption, the positive and negative electrodes and the electrolyte are tightly pressed together to achieve sealing.

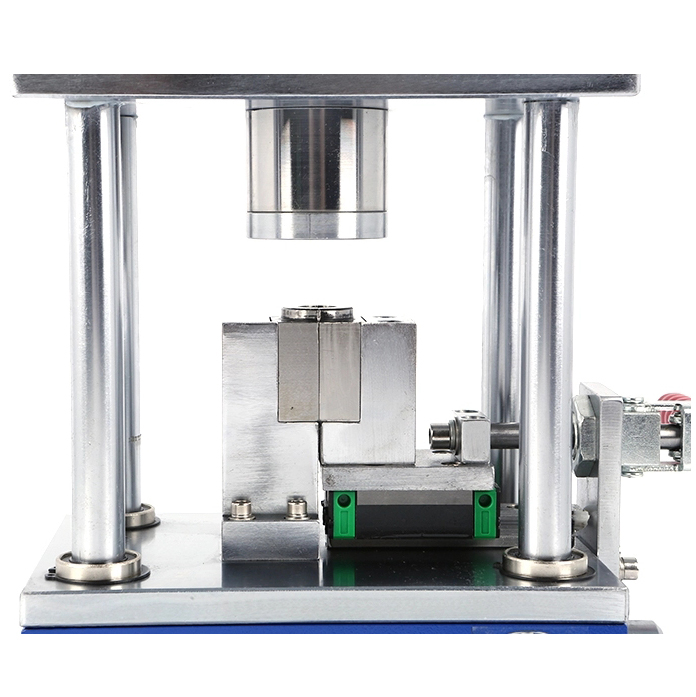

(2) Pressing technology:

Sealing machines are usually equipped with pressing devices, such as mechanical arms, cylinders, etc. After softening with heat, the pressing device applies the appropriate pressure to press the material together between the positive and negative electrodes and the electrolyte. The pressing process requires precise control of the amount and duration of pressure to ensure that the material in the sealing area is held together evenly and tightly.

(3) Vacuum sealing technology:

For some batteries with higher sealing requirements, such as lithium-ion batteries, the battery sealer may use vacuum sealing technology.Before sealing, the gas inside the battery is extracted through a vacuum pump to form a vacuum state.The heating and pressing operation is then carried out to make the material better bonded together in the vacuum state to achieve a higher sealing effect.

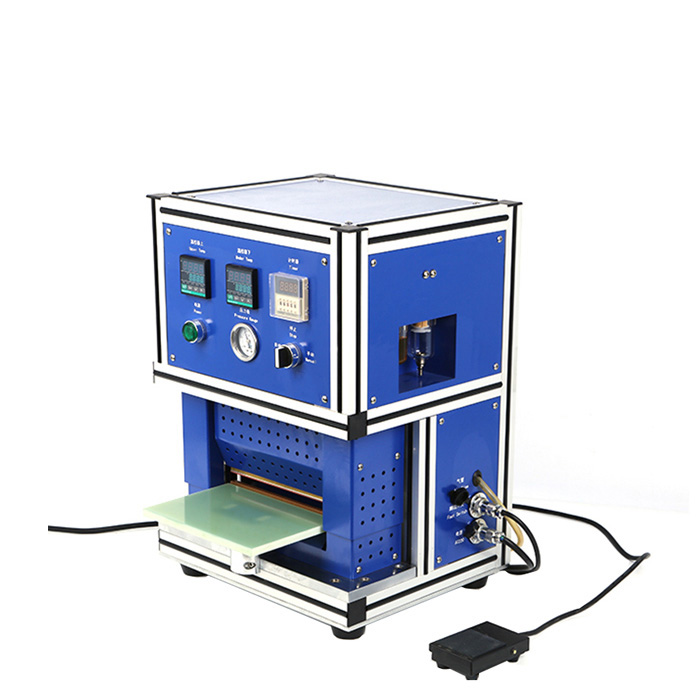

2, the type of battery sealing machine:

(1) Square battery sealing machine:

Sealing method: The square battery sealing machine usually adopts the principle of high temperature melting sealing, and uses high temperature heating to weld the battery cover and the battery housing together to achieve complete sealing.

Control accuracy: Due to the relatively simple structure of the square battery, the control accuracy of the sealing machine is usually high, which can ensure the consistency and sealing of the seal.

Degree of automation: The square battery sealing machine generally has a high degree of automation, and can achieve automatic feeding, automatic sealing and automatic detection functions.

(2) Cylinder battery sealing machine:

Sealing method: The cylinder battery sealer may require a specific sealing device to adapt to the cylindrical battery shape. Sealing methods may include pressing, welding, etc.

Control accuracy: The sealing accuracy of cylindrical batteries is equally important, because the shape of the battery has an impact on the sealing quality. The sealing machine requires precise control of the sealing pressure and temperature to ensure the tightness and safety of the battery.

Degree of automation: The degree of automation of cylindrical battery sealers is also higher, but more complex mechanical structures and control systems may be required to adapt to different models of cylindrical batteries.

(3) Pneumatic button battery sealing machine:

Sealing mode: The pneumatic button battery sealing machine adopts the pneumatic drive mode, and realizes the rapid, accurate and stable sealing operation of the battery shell through the precise sealing position control.

Control accuracy: Due to the pneumatic drive, the sealing machine has a high control accuracy, which can ensure the sealing quality of each battery is consistent.

Degree of automation: Pneumatic button battery sealer usually has a high degree of automation, simple operation, suitable for installation and use in a variety of production environments.

the battery sealing machine operation steps detailed explanation

1. Preparation:

Make sure the power to the sealer is switched on and the air supply is connected (if required by the machine). Prepare the battery to be sealed and the corresponding sealing mold. Depending on the need, it may be necessary to adjust the parameters of the sealer, such as temperature, time, pressure, etc., to adapt to different types of batteries.

2, adjust the sealing mold:

Place the battery in the mold and adjust the sealing depth to ensure that the sealing height and width meet the requirements.

If necessary, the position and Angle of the sealing mold can be adjusted to better suit the shape of the battery.

3, sealing operation:

Turn on the heat button on the machine (if the machine needs to be preheated) and wait for the machine to heat to the preset temperature.

Put the battery into the adjusted sealing mold to ensure that the battery position is correct and stable. Press the start button or the sealing button to begin the sealing process. Wait until the sealing is complete and observe the sealing quality.

advanced operation skills and troubleshooting

1. Advanced operating skills

(1) Advanced operating skills to improve sealing efficiency and quality:

Precise temperature control:

The sealing temperature is one of the key factors affecting the sealing quality. Depending on the type and material of the battery, set a precise temperature range and ensure that the sealer can maintain this temperature stably. Use a sealer with a high precision temperature control system to ensure temperature accuracy and stability.

Optimize sealing time:

Adjust the sealing time according to the size, shape and material of the battery. Too short a time may result in a weak seal, while too long a time may damage the battery or waste energy. Through experiments and tests, the best setting of sealing time is found and applied in actual production.

Mold selection and maintenance:

Choose the mold that matches the type of battery and ensure the accuracy and durability of the mold. Clean and maintain the mold regularly to remove dirt and impurities on the surface of the mold to keep it in good working condition.

2. Troubleshooting

(1)Loose seal

The reason:

The temperature is not high enough or the sealing time is not long enough.

Seal verbally damaged or worn.

Solution steps and methods:

Increase the sealing temperature or extend the sealing time.

Check the seal and replace it with a new one if there is any problem.

(2)Motor fault

The reason:

The motor is damaged.

Electrical failure of the motor, such as abnormal power supply voltage, loose motor line, abnormal connection between the motor connector and the motor.

Solution steps and methods:

When the motor is damaged, it needs to be replaced. The specific steps are: first remove the motor and drive shaft, remove the original motor, replace the new motor of the same model, and then install the motor and drive shaft back to the machine, and finally turn on the power to test whether the battery sealer is running normally.

When the motor is electrically faulty, it is necessary to check the power supply voltage, the motor line, the connection between the motor connector and the motor, and whether the sensor is damaged.

Conclusion and prospect

1, technological innovation: With the continuous development of science and technology, battery sealing machine technology will also usher in new innovations. For example, more advanced automation technologies may be used to enable more efficient and precise sealing processes.

2, environmental protection and energy saving: with the global attention to environmental protection and energy saving continues to increase, battery sealing machine technology will also develop in the direction of more environmental protection and energy saving.

3, diversified applications: battery sealing machine is not only used in battery manufacturing, but also can be widely used in other fields.