Introduction and Operation Guide for Lab Battery Winder

In the field of battery manufacturing, battery winder machines play a crucial role in enhancing production efficiency and ensuring battery quality. Specifically, in laboratory environments, precision control of the battery winding process is essential for studying battery performance and optimizing production techniques. This article aims to provide a comprehensive introduction to laboratory battery winding machines and elaborate on their operation procedures.

1. Overview of Laboratory Battery Winding Machines

2. Features of Laboratory Battery Winding Machines

3. Operation Process of Laboratory Battery Winding Machines

4. Common Issues and Troubleshooting

5. Conclusion

6. Choosing the Right Laboratory Battery Winding Machine

1. Overview of Laboratory Battery Winding Machines

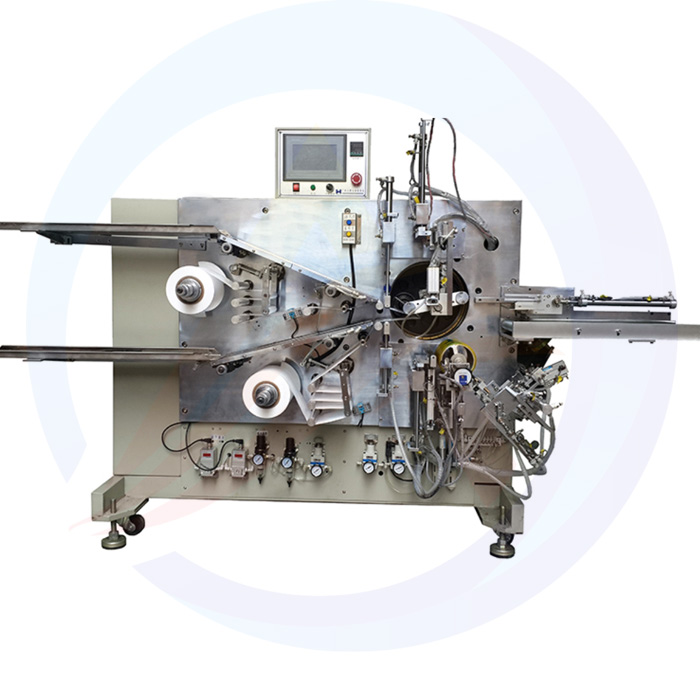

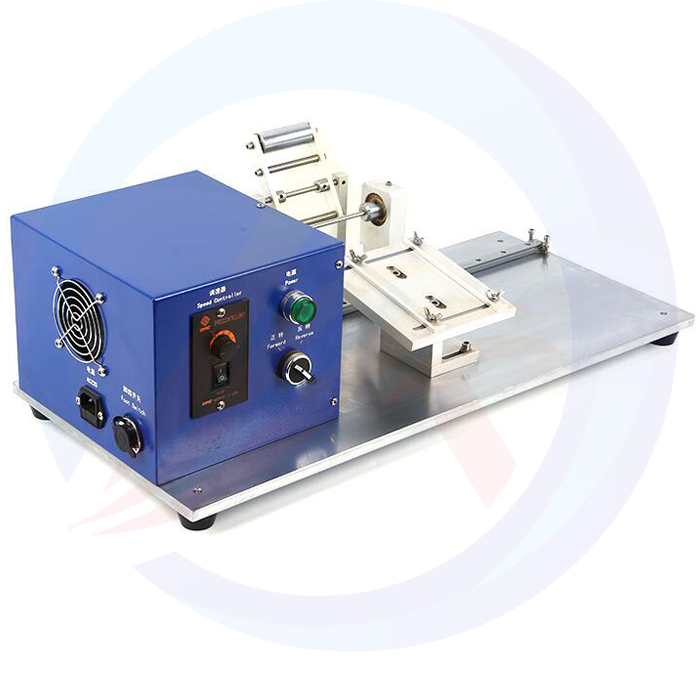

Laboratory battery winding machines are specifically designed for use in laboratory settings, where they are tasked with winding lithium battery cells. These machines assemble positive and negative electrodes, along with separators, into cell cores through a continuous rotation process. Compared to industrial-scale winding machines, laboratory models offer higher precision, greater flexibility, and a more compact design, making them ideal for laboratory applications.

The main components of laboratory battery winding machines include the winding mechanism, material feeding system, and control system. The winding mechanism is the heart of the device, responsible for precisely winding the electrodes and separators according to set parameters. The material feeding system ensures a smooth and continuous supply of materials to the winding mechanism, while the control system oversees the entire operation and allows for parameter adjustments.

2. Features of Laboratory Battery Winding Machines

2.1 High Precision:

Laboratory battery winding machines utilize advanced control systems and precise transmission mechanisms to achieve high-precision winding processes, thus ensuring the quality of the cells produced.

2.2 Flexibility:

The battery winder machines offer significant flexibility, allowing for adjustments in winding speed, tension, and other parameters to accommodate different cell specifications and types.

2.3 Safety:

Laboratory battery winding machines incorporate multiple safety measures, such as overload protection and short-circuit prevention, to ensure the safety of operators and equipment.

2.4 User-Friendliness:

The machines are designed with a user-friendly interface, making them easy to operate and understand for laboratory personnel.

3. Operation Process of Laboratory Battery Winding Machines

3.1 Preparation

Before operating the laboratory battery winding machine, it is essential to prepare the necessary materials and settings. First, check the power supply and pneumatic pressure to ensure they are within normal operating ranges. Then, prepare the electrodes and separators, ensuring they are clean and free of contaminants. Finally, set the winding parameters according to the experimental requirements, including winding speed, tension, and other relevant settings.

3.2 Starting the Machine

Once the preparations are complete, turn on the power switch to start the machine. After the machine initializes, set the desired winding length, tension, and other parameters. Monitor the machine's status to ensure it is operating normally.

3.3 Positioning the Cell

Place the prepared cell onto the winding mandrel of the machine, ensuring it is aligned with the winding direction. Secure the cell in place using the machine's clamps to prevent movement during the winding process.

3.4 Winding Process

Once the cell is properly positioned, initiate the winding process by pressing the start button. The machine will automatically begin winding the cell according to the preset parameters. During the winding process, monitor the machine's status and the cell's winding condition. If any abnormalities occur, such as excessive winding speed or tension, immediately stop the machine and make necessary adjustments.

3.5 Cutting the Copper Strip

When the cell reaches the desired length, the machine will automatically or manually trigger the cutter to sever the copper strip. Wait for the machine to eject the wound cell and remove it for further processing.

3.6 Machine Cleanup

After completing the winding process, clean the machine thoroughly. Turn off the power and pneumatic pressure, and remove any residual materials or waste from the machine. Inspect and maintain the various components to ensure the machine's long-term stability and reliability.

4. Common Issues and Troubleshooting

4.1 Copper Strip Breakage during Winding

Cause: Excessive or insufficient tension of the copper strip; poor quality of the copper strip; blunt cutting blade.

Solution: Adjust the tension of the copper strip; replace the copper strip with a higher-quality one; replace the cutting blade with a sharper one.

4.2 Unstable Winding Speed

Cause: Malfunction of the transmission mechanism; issues with the control system.

Solution: Inspect and repair the transmission mechanism; troubleshoot and repair the control system.

4.3 Deformation or Damage to the Wound Cell

Cause: Excessive winding tension; poor quality of the cell; improper operation.

Solution: Adjust the winding tension; replace the cell with a higher-quality one; ensure strict adherence to the operating procedures.

5. Conclusion

Laboratory battery winding machines are essential tools in laboratory environments, enabling the production of high-quality lithium battery cells for research and experimentation. Operating these machines requires strict adherence to operating procedures and attention to machine maintenance and troubleshooting. By understanding the basic

6. Choosing the Right Laboratory Battery Winding Machine

In today's rapidly evolving battery technology landscape, having the right tools for battery research and development is crucial. Among these tools, the laboratory battery winding machine plays a pivotal role in producing high-quality, consistent battery cells for testing and evaluation. However, with a wide range of options available, choosing the right machine can be a daunting task. Here's a guide to help you make an informed decision.

6.1 Understand Your Needs

Before shopping for a laboratory battery winding machine, it's essential to understand your specific needs. Consider factors such as the type of battery cells you'll be producing (e.g., cylindrical, prismatic, or pouch), the required production volume, and the precision level needed for your experiments. This will help you narrow down the selection of machines that best suit your requirements.

6.2 Evaluate Machine Capabilities

When evaluating different machines, pay attention to their capabilities and specifications. Look for machines that offer high precision and accuracy in the winding process, ensuring consistent cell quality. Additionally, consider the machine's speed and throughput, as well as its ability to handle different materials and sizes of battery cells.

6.3 Consider Automation Level

Automation is a significant factor to consider when choosing a laboratory battery winding machine. Fully automated machines can significantly reduce labor costs and improve production efficiency. However, semi-automated or manually operated machines may be more suitable for low-volume production or research projects with specific requirements. Evaluate your needs and budget to determine the right level of automation for your application.

6.4 Check for Flexibility and Scalability

As battery technology continues to evolve, you may need to adapt your production processes accordingly. Therefore, it's essential to choose a laboratory battery winding machine that offers flexibility and scalability. Look for machines that can handle a variety of battery cell sizes and materials, as well as machines that can be easily upgraded or modified to meet future needs.

6.5 Evaluate User-Friendliness and Support

User-friendliness and technical support are also important considerations. Choose a machine with an intuitive user interface and easy-to-follow operating instructions to minimize training requirements and improve operator efficiency. Additionally, ensure that the manufacturer provides reliable technical support and spare parts availability to ensure the smooth operation of your machine.

6.6 Consider Cost and Value

Finally, when making your decision, consider the cost and value of the laboratory battery winding machine. Compare the prices of different machines and evaluate their features and capabilities to determine the best value for your money. Remember that the most expensive machine isn't always the best choice, and a machine that offers the right capabilities for your needs may be a more cost-effective option.

In conclusion, choosing the right laboratory battery winding machine requires careful consideration of your specific needs, the machine's capabilities and specifications, the level of automation, flexibility and scalability, user-friendliness and support, and cost and value. By following these guidelines, you can ensure that you select a machine that will help you produce high-quality battery cells for your research and development efforts.