How to choose roller press machine?

With so many types of rollers to choose from, how do we choose the suitable roller?

We will discuss what a roller press is and what parts it contains.

Let's get straight to the point.

What is a roller press machine?

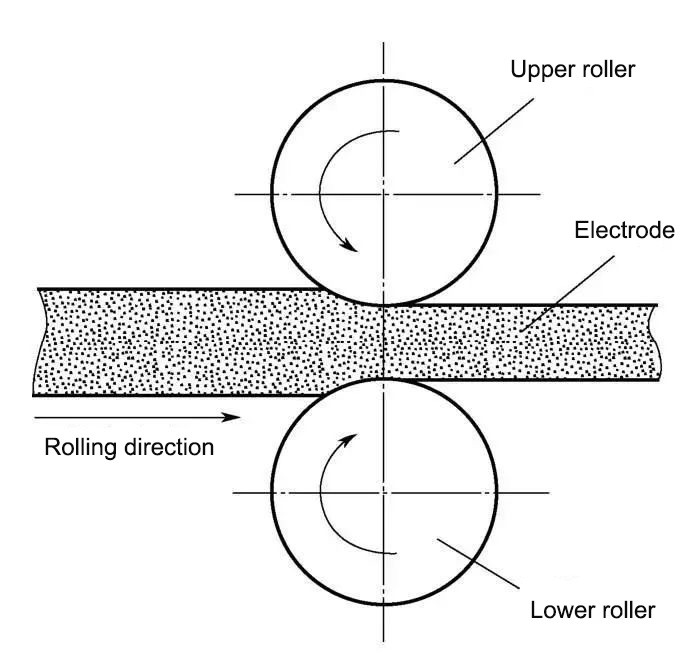

A roller press, also known as a rolling mill, is a mechanical device that deforms, breaks or mixes materials under pressure through the pressure action between two or more rollers. In the lithium battery manufacturing process, the roller press is mainly used to roll, densify and mix the electrode material to improve the density, consistency and electrochemical performance of the electrode.

1. Roller pressing is a process used to compact lithium battery electrode sheets, which can increase the energy density and prevent the electrode material from falling off.

2. Before rolling, it is necessary to dry the coated pole sheet to a certain extent, otherwise the coating may fall off.

3. When rolling, it is necessary to control the amount of compaction of the electrode sheet. Excessive compaction may affect the deimpingement of lithium ions and the bonding of active substances of the electrode material, and may cause the fracture of the electrode sheet in serious cases.

4. Rolling is one of the key processes in the manufacturing process of lithium battery pole sheet, and its rolling precision has a great impact on the performance of lithium battery.

What parts does the lithium battery roller press include?

1. Unwinding machine

In the continuous rolling production line, the unwinding machine is the first process, its main function is to support the lithium battery positive material roll pulled out of the raw material warehouse, and fix it at the entrance of the continuous rolling mill. The performance of the unwinding machine directly affects the stability of the subsequent process and the quality of the product. In order to ensure continuous and stable rolling, the unwinding machine should have a constant tension control function to adapt to different diameters and masses of material rolls.

2. Front taping device

The main function of the front bonding device is to connect the cathode material of the lithium battery with the previous roll of rolled strip before it enters the continuous mill. This link is crucial to ensure the continuity of production, so the front taping device needs to have efficient, accurate and reliable connection capabilities. The common connection methods are welding and gluing, and the appropriate connection method should be selected according to the material characteristics and production requirements.

3. Dust removal device

The cathode material of lithium battery is easily polluted by dust and impurities in the rolling process, which not only affects the appearance quality of the product, but also has an adverse effect on the performance of the battery. Therefore, the dust removal device is an indispensable part of the continuous rolling production line. The dust removal device should have the characteristics of high efficiency filtration, low noise, energy saving and environmental protection, and should also be regularly maintained and cleaned according to the production environment and material characteristics.

4. Flattening (stretch wrinkle) device

The main function of the flattening device is to flatten the positive electrode material of the lithium battery and remove the wrinkles and unevenness on the surface of the material. In the rolling process, the material is rolled by multiple rolls, which is easy to produce wrinkles and unevenness, which not only affects the appearance quality of the product, but also causes difficulties for the subsequent coating and assembly. Therefore, the design and optimization of flattening device is of great significance to improve product quality and production efficiency.

5. Roll press

Roller press is the core equipment in continuous rolling production line, which rolls the cathode material of lithium battery to the required thickness and width through continuous rolling of multiple rolls. The performance of the roller press directly affects the dimensional accuracy, surface quality and production efficiency of the product. In order to ensure continuous and stable rolling, the roller press should have the characteristics of high precision, high rigidity and high stability, and it should also have the functions of constant tension control and automatic thickness adjustment.

How to choose lithium battery roller press?

When selecting a lithium battery roller press, a number of factors need to be considered to ensure that the selected equipment can meet the production needs, and has the characteristics of efficiency, stability and safety. The following is a set of solutions to help you make an informed decision when choosing a lithium battery roller press:

1. Determine the technical specifications and parameters of the roller press:

In the selection of lithium battery roller press, we must first clarify the requirements of the production process, such as the thickness, width, hardness and so on. According to these requirements, the roller press with the corresponding technical specifications and parameters is selected to ensure that the equipment can meet the needs of the production process.

2. Consider the performance characteristics of the roller press:

The performance characteristics of the roller press are one of the key factors in selecting the equipment. Understanding the characteristics of pressure regulation, speed control, material adaptability and operational stability of the roller press helps to ensure that the equipment can achieve the required quality and efficiency during the production process.

3. Understand the safety performance of the roller press:

Safety performance is one of the important factors to consider when choosing a lithium battery roller press. Choose a roller with safety protection and an early warning system to ensure the safety of the operator and the stable operation of the equipment.

4. Consider the reliability of the roller press:

When selecting a lithium battery roller press, it is necessary to consider the reliability and durability of the equipment. Understanding the failure rate, maintenance costs, and after-sales service of the equipment helps to ensure that the equipment can maintain good performance during long-term use.

5. Compare the quotations and schemes of different suppliers:

When selecting a lithium battery roller press, it is necessary to compare the quotations and schemes of different suppliers. Knowing the supplier's qualification, product quality and service information helps to choose the supplier with reliable quality, reasonable price and considerate service.

6. Refer to the evaluation and experience of other users:

Understanding the evaluation and use experience of other users on different brands and models of lithium battery rollers helps to better evaluate the performance of the equipment, reliability and after-sales service, and provides a valuable reference for the selection of equipment.

Conclusion

In practical applications and the selection of roller press lithium battery roller press need to consider a number of factors, including technical specifications and parameters, performance characteristics, safety performance, reliability, quotation and program and user evaluation and use experience. By comparing the equipment and programs of different suppliers, and referring to the experience of other users, the comprehensive performance of the equipment can be better evaluated, and the high-quality lithium battery roller press suitable for production needs can be selected, and at the same time, the various parts of the equipment need to cooperate with each other and work together to achieve the efficient, stable and continuous production of lithium battery cathode materials.