"Lithium battery welding machine" and user questions answered

Lithium battery welding machine is a kind of equipment specially used for welding lithium batteries, also known as lithium battery spot welding machine. It usually uses resistance welding technology, which uses the resistance heat generated by the current through the two electrodes to melt the solder, so as to achieve the welding of the battery. The following is a more detailed introduction to the lithium battery welding machine

I. The main components of the welding machine:

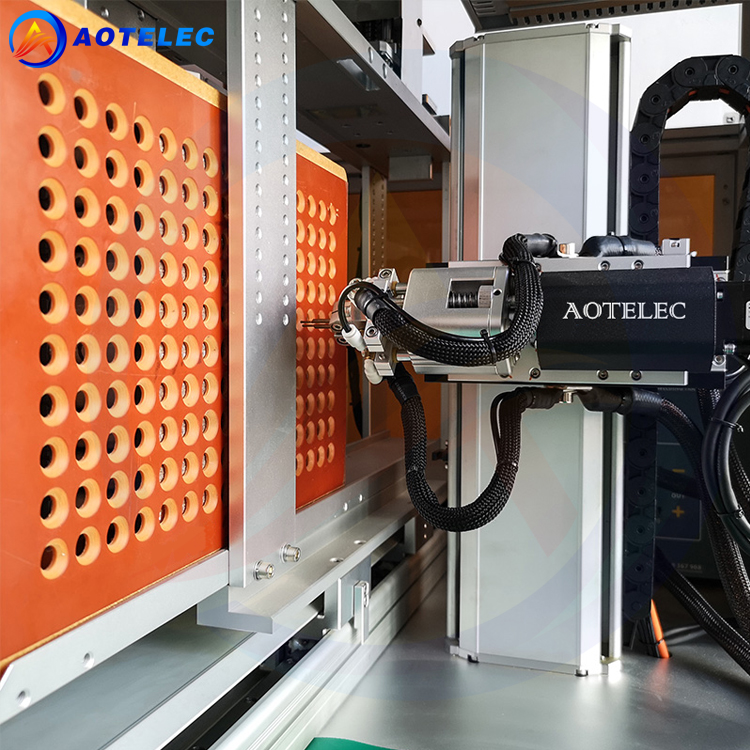

1) Welding device:

The device is the core part of the welding machine, including the welding head, welding electrode and control system. The welding head is usually made of a material with good thermal conductivity such as copper or chrome-zirconium copper, and the shape and size of the electrode vary according to different welding needs. The control system is used to control the temperature and pressure of the welding head to ensure the quality and stability of the welding.

2) Power system:

The system provides power for the welding machine, usually using AC or DC power supply, according to different welding needs to choose the right power supply.

3) Cooling system:

The system is used to cool the welding device and the power system to ensure the normal operation and service life of the equipment.

4) Auxiliary parts:

Including bracket, fixture, workbench, etc., used to fix and position the lithium battery to ensure the accuracy and quality of welding.

II. The use of welding machine:

1) Preparation:

First of all, you need to prepare lithium battery, solder, solder and other materials, and place the lithium battery on the work table, adjust the position and Angle.

2) Welding process:

Place the solder between the electrodes of the welding head, adjust the position and pressure of the electrodes, turn on the power supply, and make the welding head generate heat. When the solder and the lithium battery contact, the solder will melt and penetrate between the solder and the lithium battery, forming a good welding effect.

3) Post-welding treatment:

After the welding is completed, it is necessary to check the quality and stability of the welding, and make corresponding adjustments if necessary. At the same time, it is necessary to pay attention to cleaning residual solder and debris, and keep the working area clean.

III. Process flow

Through the human-machine interface software, the spot welding path, battery formula and other parameters are set, and the motion controller automatically completes the following functions: manually loading the battery and nickel sheet to the fixture → placing it in the fixture slot → automatic alignment of the welding needle to the battery → automatic extension of the welding head to the battery → discharge welding of the welding machine; Equipment configuration sound and light alarm, spot welding complete automatic shutdown, complete alarm, fault alarm and so on. Operating parameters can be set according to the actual requirements of customers.

IV. The advantages of welding machine:

1) High efficiency and stability:

lithium battery welding machine adopts resistance welding technology, which can achieve fast, stable and reliable welding effect and improve production efficiency.

2) Strong applicability:

suitable for lithium battery welding of various sizes and shapes, the position and size of the electrode can be adjusted according to different needs.

3) Simple operation:

The welding machine usually adopts automatic control technology, the operation is simple and easy to understand, which can reduce the influence of human factors on the welding quality.

4) Easy maintenance:

The welding machine is simple and compact, convenient for daily maintenance and maintenance.

5) Safe and reliable:

The welding machine uses low voltage and current work, reducing the safety risk in the operation process. At the same time, it has a variety of protection functions such as overcurrent protection and temperature protection, which improves the reliability and safety of the equipment.

6) High economic efficiency:

Through the use of welding machine can improve production efficiency and product quality, reduce production costs and scrap rate, thereby improving economic efficiency.

V. The use of lithium battery welding machine need to pay attention to:

1) Safe operation: The operator should be familiar with the safe operation procedures of the equipment to ensure that no accidents occur during the operation. At the same time, it is necessary to regularly check whether the safety protection measures of the equipment are intact and effective.

2) Maintenance: Regular maintenance and maintenance of the equipment, including cleaning the oxide on the electrode, replacing the worn parts, etc., to ensure the normal operation and service life of the equipment.

3) Material selection: Appropriate solder sheets and solder materials should be selected according to different welding needs to avoid poor welding results or damage to equipment due to improper selection of materials.

4) parameter adjustment: according to the size of the lithium battery, thickness and other factors to adjust the electrode position and pressure and welding time and temperature and other parameters to ensure the quality and stability of welding.

5) Quality inspection: After the welding is completed, quality inspection should be carried out to check whether there is virtual welding, missing welding and other phenomena. If necessary, timely adjustment and treatment should be made.

6) Environmental requirements: To ensure the environmental health and cleanliness of the working area, to avoid dust, debris and other effects on the normal operation and service life of the equipment. At the same time, the appropriate working temperature and humidity should be maintained to avoid the equipment working in extreme environments.

6) Training and education: Necessary training and education should be carried out for new operators, so that they are familiar with the basic operation and safety requirements of the equipment, and improve operational skills and work responsibility.

7) Maintenance and accessories: When the equipment fails, it should be repaired and dealt with in time to avoid greater losses caused by the equipment working with disease. At the same time, the maintenance accessories and tools of the equipment should be properly kept for timely maintenance and replacement.

8) Record and traceability: It is necessary to establish a sound equipment use record and traceability system, record the operating status and maintenance of the equipment and other information, so as to find problems and deal with them in time. At the same time, it is necessary to ensure the traceability of the equipment, so that when problems occur in the production process, they can be quickly located and solved.

VI. Summary

Lithium battery welding machine is an efficient, stable and safe equipment, which is widely used in the production and manufacturing of lithium batteries. Through proper operation and maintenance, you can ensure the normal operation and service life of the equipment, improve production efficiency and product quality, and reduce production costs and scrap rates.

VII. Netizen questions and Answers:

Causes and solutions of laser welding penetration

The main reason for laser welding penetration is that the welding current is too large, the welding speed is too small or the gap is too large.

1) In order to avoid this situation, the following measures can be taken:

a. Adjust the parameters of the laser welding machine, according to the material and thickness of the workpiece, reasonable selection of laser power, spot diameter, focal length and other parameters.

b. Reasonable selection of welding position, should choose the material is thin or the weld is narrow position for welding, avoid the material is thick or the weld is wide position for welding.

c. Control the welding speed, appropriately improve the welding speed, and strictly control the installation gap.

d. Pay attention to the finishing of both sides of the groove and between the layers of the weld, so that the fusion between the melted metal and the fused metal and the base metal are fully fused.

2) If welding penetration has occurred, you can try the following measures to make up for it:

a. Reduce the welding current or increase the welding speed to reduce the heat input.

b. Add filler metal to the welded position and weld again.

c. If welding penetration is serious, you can add a backing plate on the back of the workpiece to prevent welding penetration.