With the wide application of lithium batteries in various fields, the demand for efficient and reliable battery manufacturing equipment is also increasing. As one of the key equipment in the battery manufacturing process, the lithium battery grooving machine plays an important role in slotting the battery housing to provide better sealing and safety.

1, what is lithium battery slotting machine

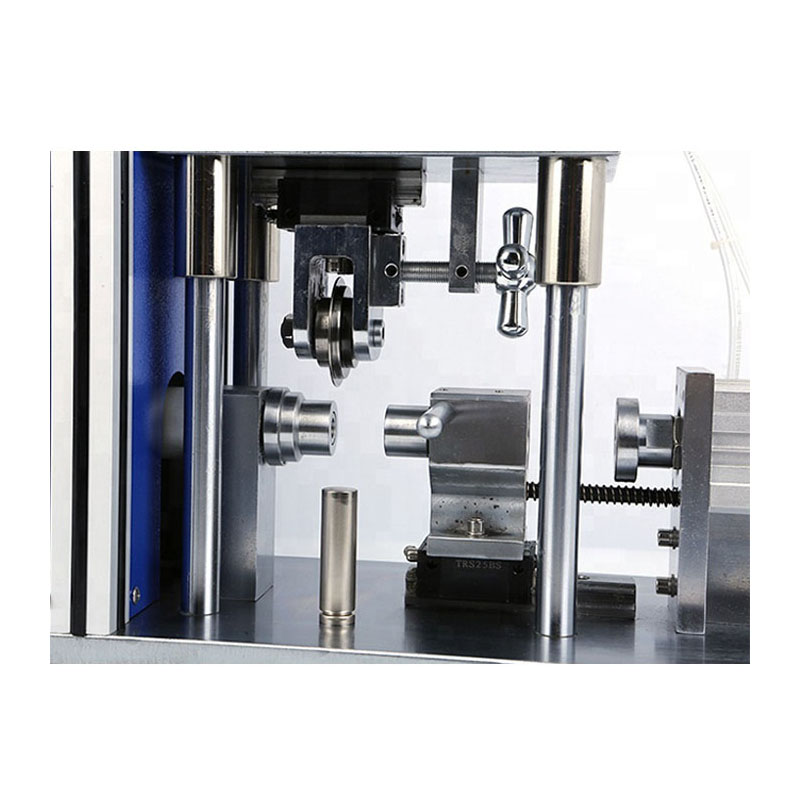

The lithium battery slotting machine is a special equipment used for slotting the lithium battery shell. Grooving refers to cutting grooves on the battery housing to meet the requirements of battery assembly and battery packaging. The slotting machine usually consists of a mechanical structure, a control system and a tool, and can perform precise slotting operations on the battery housing.

2, the working principle of lithium battery slotting machine

(1) Mechanical pressure processing: The lithium battery slotting machine uses the role of mechanical pressure to apply the tool or mold to the battery housing to form a slotted incision. This machining method ensures the consistency and accuracy of the grooving.

(2) Cutting or compression slotting: lithium battery grooving machine can be achieved by cutting or compression. Cutting slotting is suitable for metal shell, using a tool to cut the shell to form a groove. Compression slotting is suitable for soft-pack batteries, using a die to apply pressure to the flexible housing to create a slotting.

(3) Automatic control: Modern lithium battery grooving machine is equipped with an advanced automatic control system, which can monitor and adjust the parameters in the slotting process in real time, such as pressure, speed and tool position. This ensures consistent slotting quality and system stability.

3, the role of lithium battery grooving machine

(1) Improve the sealing: The lithium battery grooving machine can form a groove on the battery housing through the slotting process, so that the battery housing and the gasket are closely combined, improving the sealing performance of the battery, preventing the battery from leaking, and improving the safety of the battery.

(2) Enhance strength and stability: slotting can change the structure of the battery housing, increase the rigidity and strength of the housing, and improve the structural stability of the battery. This helps prevent battery deformation, short circuits, and damage to the battery's internal components, thereby improving battery life and performance stability.

(3) Reduce the internal resistance: The lithium battery grooving machine can control the width and depth of the slotting, making the connection between the battery housing and the internal components more solid, reducing the internal contact resistance of the battery, thereby reducing the internal resistance of the battery and improving the energy conversion efficiency of the battery.

4、the operation process of the lithium battery slotting machine

(1) Setting parameters: According to the battery model and requirements, set the appropriate slot parameters, such as slot depth, width and speed. These parameters directly affect the quality and efficiency of the grooving.

(2) Prepare the battery housing: clean and inspect the battery housing to ensure that its surface is free of impurities and damage. Place the battery housing on the positioning device of the slotting machine and fix it as required.

(3) Start slotting: Start the automatic control system of the slotting machine, and extend the tool or mold into the inside of the battery housing according to the set parameters, and start slotting. The control system automatically adjusts the pressure, speed and position to ensure the consistency and accuracy of the slot.

(4) Test the quality of the slot: After the completion of the slot, the quality of the slot is tested, including the width, depth and shape of the slot. According to the inspection results, the parameters of the slotting machine are adjusted and optimized to ensure that the slotting quality meets the requirements.

5、Conclusion

The slotting machine for lithium battery plays an important role in the manufacturing process of lithium battery. Through its machining principle and automatic control system, the lithium battery grooving machine can improve the tightness, strength and stability of the battery, reduce the internal resistance, thereby improving the safety, performance and life of the lithium battery.