Tube furnace and muffle furnace

Tube furnace and muffle furnace are common heating equipment, but they are in the structure, use, performance characteristics and other significant differences.

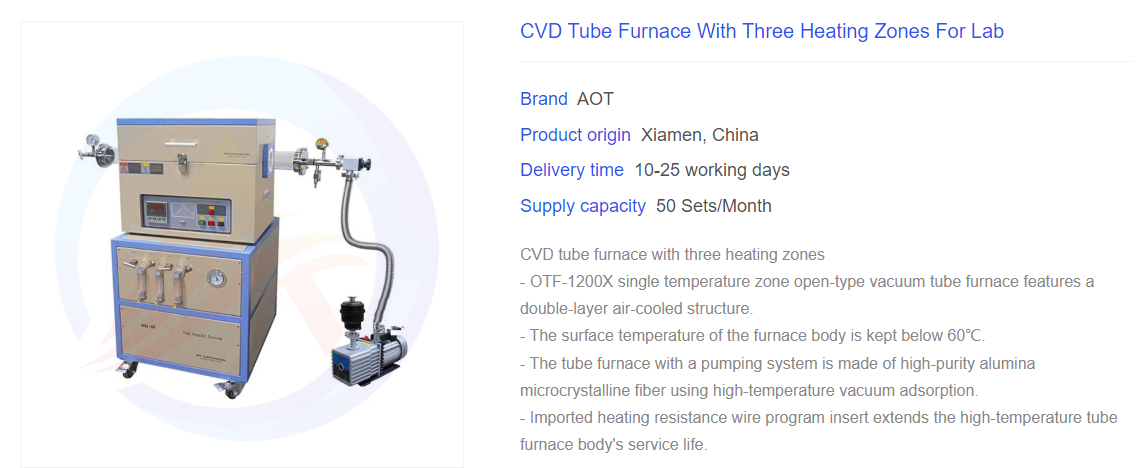

Tube furnace, as the name suggests, is a furnace chamber is a tubular structure of the heating equipment. It is usually composed of furnace tube, heating elements, control systems and auxiliary equipment and other parts. The furnace tube is the main part of the tube furnace and is often made of high-temperature and corrosion-resistant materials, such as quartz, ceramic or metal. The heating element is responsible for providing heat so that the material in the furnace tube reaches the required heating temperature. The control system is used to accurately control the temperature inside the furnace to ensure the stability and safety of the heating process.

Tube furnaces are widely used in material processing, chemical synthesis and experimental research. In material processing, it can be used for metal smelting, ceramic sintering, glass melting and other processes; in the field of chemical synthesis, it provides a stable and controllable heating environment for organic synthesis, inorganic synthesis and catalyst preparation; in experimental research, tube furnace is one of the indispensable equipments, which can be used for the study of the thermal properties of the materials, the dynamics of the chemical reaction process as well as the synthesis and preparation of new materials and so on.

1) High-efficiency heating:

Tube furnace adopts high-efficiency heating elements, such as resistance wire, electric heat pipe, etc., which can quickly convert electric energy into heat energy and realize rapid heating. At the same time, the materials inside the furnace tube are heated uniformly by heat radiation and convection, etc., which ensures the uniformity and consistency of the heating effect.

2) Precise temperature control:

Tube furnace is equipped with advanced temperature control system, which can realize precise temperature control. Users can set the heating temperature, heating rate and holding time according to their needs to ensure that the heating process meets the process requirements.

3) Compact structure:

Tube furnace adopts integrated design, compact structure and small footprint. This allows it to be flexibly arranged in laboratories, factories and other environments with limited space, improving space utilization.

4) Easy to operate:

The operating interface of the tube furnace is simple and clear, easy to get started. Users only need to control panel or remote control system to realize the equipment start, stop, temperature adjustment and other operations, greatly reducing the difficulty of operation.

Advantages of tube furnace

1) Precise control:

Tube furnace usually has a high temperature control accuracy, can accurately control the temperature of the heating process, to meet the strict requirements of the temperature of the experimental and production needs.

2) Atmosphere control:

Its tubular structure is conducive to the realization of atmosphere control, different gases can be passed into the furnace to change the atmosphere environment, suitable for experiments and production processes that require specific atmosphere conditions.

3) Compact structure:

Tube furnaces have a compact structure and a small footprint, making them suitable for use in laboratories or where space is limited.

4) Easy to operate:

Some high-end tube furnaces are equipped with advanced control systems, which can realize intelligent operation and remote monitoring, reducing the difficulty of operation.

5) Low energy consumption:

Compared with other types of equipment, tube furnace can save a lot of energy costs when used for a long time.

Disadvantages of tube furnace

1) Limited production capacity:

Due to the fixed diameter of the furnace, the production capacity of the tube furnace is relatively small, which is not suitable for mass production.

2) Complicated atmosphere control:

Although tube furnace can realize atmosphere control, the actual operation requires precise control of gas flow and ratio, the operation is relatively complicated.

3) Maintenance cost:

In the process of long-term use, the tube furnace tube and other components may wear or aging, need to be regularly replaced and maintained, increasing the maintenance cost.

Muffle furnace, full name “muffle furnace”, is a kind of equipment that can provide high temperature heating environment. It is usually composed of furnace body, electric heating element, temperature control system and other parts. The furnace body is generally made of high-temperature-resistant ceramic or refractory materials to withstand high temperatures and prevent heat loss. The electric heating element is the core component of the muffle furnace, which is heated by electric current to generate heat, and then the heat is transferred to the materials in the furnace body through heat conduction and radiation. The temperature control system is responsible for controlling the temperature of the furnace body and temperature changes to ensure that the material is heated within the required temperature range.

Muffle furnace is widely used in industrial production and scientific research experiments. In industrial production, it is used in the melting of metal materials, rolling, welding and other processes for heating treatment to improve the quality and performance of products. In scientific research experiments, muffle furnace is used to carry out a variety of high-temperature experiments, such as material synthesis, chemical reactions, sintering ceramics and so on. In addition, muffle furnace is also used in the field of environmental protection in the incineration treatment, glass industry, molten glass and other processes.

1) High-temperature heating:

Muffle furnace is able to use electric energy as energy source, through the electric heating element will be converted into thermal energy, to provide high-temperature heating environment. This makes it able to meet the needs of various high temperature processes.

2) Uniform heat field:

The design of the muffle furnace body enables the heat to be evenly distributed throughout the furnace chamber, forming a uniform heat field. This makes the material in the heating process can be uniformly heated, avoiding localized overheating or overcooling.

3) High-precision control:

The temperature control system of the muffle furnace can realize high-precision temperature control. Users can set the heating temperature, heating rate and holding time and other parameters as needed to ensure that the heating process meets the process requirements.

4) Widely used:

Because the muffle furnace has the characteristics of high temperature heating and uniform heat field, it is widely used in various fields. Whether it is industrial production of metal processing, glass manufacturing and other processes, or scientific research experiments in the synthesis of materials, chemical reactions and other research processes, are inseparable from the muffle furnace support.

Advantages of muffle furnace

1) High-temperature heating:

Muffle furnace can work stably at high temperatures, generally up to 1400 ℃ or more, suitable for experiments and production processes that require high-temperature heating.

2) Mass production:

Muffle furnace chamber is larger, can accommodate more materials for heating treatment, suitable for mass production.

3) Temperature uniformity:

Muffle furnace can realize uniform temperature distribution in the whole furnace chamber, to ensure that the material is heated evenly.

4) Simple operation:

The operation of the muffle furnace is relatively simple, users are easy to get started.

5) Widely used:

Muffle furnace is widely used in the melting of metal materials, sintering, heat treatment and other processes, as well as scientific research experiments in the high temperature heating needs.

Muffle furnace disadvantages

1) Long preheating time:

Muffle furnace usually requires a long preheating time to reach the required working temperature, increasing the production time and cost.

2) Complex structure:

The structure of muffle furnace is relatively complex and requires a high level of skill to operate and maintain. If the operator does not have the relevant skills, it may affect production efficiency and product quality.

3) Unable to control the chemical elements:

Although the muffle furnace is able to heat the workpiece and reach the target temperature, it is unable to accurately control the changes of the chemical elements in the metal material. If special chemical treatment of the workpiece is required, additional equipment or processes may be needed.

In summary, tube furnaces and muffle furnaces each have their own unique advantages and disadvantages. When choosing which equipment to use, comprehensive consideration needs to be made based on specific application scenarios and needs.