1. What is a lithium battery tester

2. the main function of lithium battery testing machine

3. Characteristics and advantages

4. Operation process of lithium battery testing machine

1. What is a lithium battery tester

Lithium battery tester is a device specifically used to evaluate and analyze the performance of lithium batteries. It can simulate the charging and discharging process of the battery under different operating conditions, and accurately measure the key parameters such as the capacity, voltage, internal resistance and cycle life of the battery. Through the automated test process, the lithium battery tester can efficiently test a large number of battery samples in parallel, improving the test efficiency and accuracy. This equipment plays an important role in the research and development, production, quality control and after-sales maintenance of lithium batteries, helping to ensure stable, safe and reliable battery performance. At the same time, the lithium battery tester also has the function of data recording and analysis, which can provide users with detailed test reports and provide strong support for the improvement and optimization of battery performance.

2.the main function of lithium battery testing machine

(1) Capacity test: By charging and discharging the battery, it accurately measures the amount of electricity that the battery can store and release, that is, the capacity of the battery.

(2) internal resistance test: Measure the size of the internal resistance of the lithium battery, the size of the internal resistance directly affects the working efficiency and heat output of the battery, and has an important impact on the battery performance.

(3) Cycle life test: simulate the charge and discharge cycle of the battery during actual use to evaluate the life and stability of the battery. This is of great significance for predicting battery life and improving battery design.

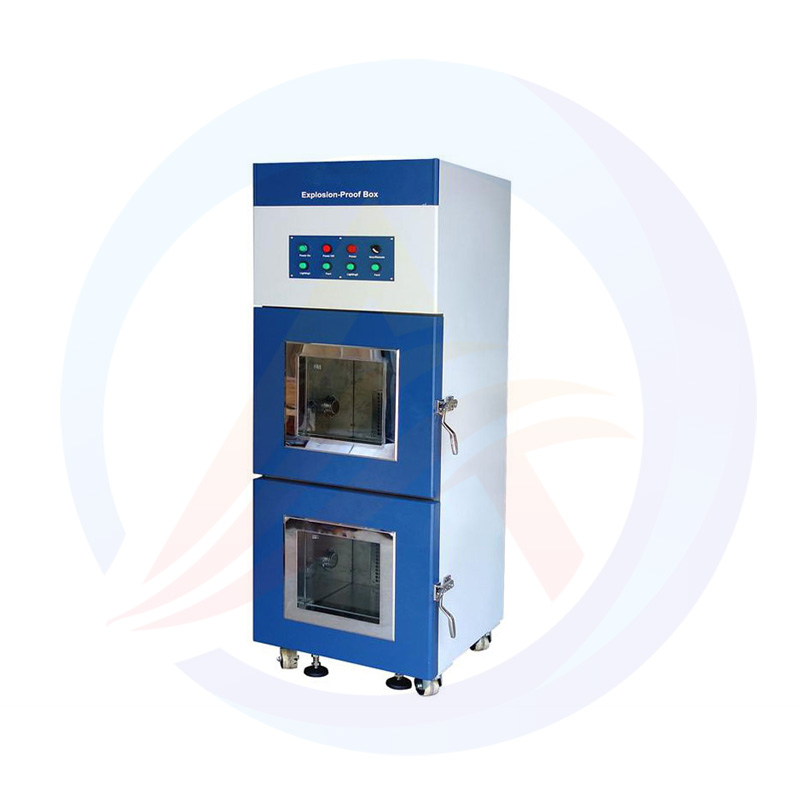

(4) Safety performance test: For the possible safety risks of lithium batteries, such as overcharge, overdischarge, short circuit, extrusion, high temperature and other conditions, evaluate the reaction of the battery under these extreme conditions to ensure the safety of the battery.

3. Characteristics and advantages

(1) Multi-channel testing: Some high-end lithium battery testing machines have the ability to conduct parallel testing of multiple battery samples at the same time, which greatly improves the detection efficiency.

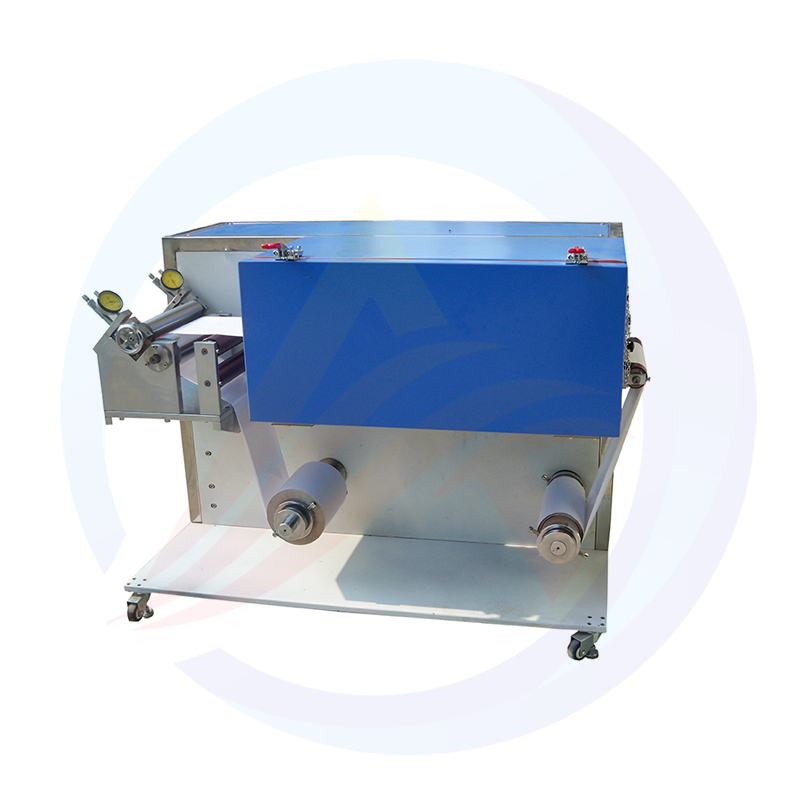

(2) Accurate measurement: The use of high-precision sensors and advanced measurement technology to ensure the accurate measurement of battery charging and discharge capacity, voltage, current and temperature parameters.

(3) Program control: Users can set and adjust the charge and discharge mode according to different test requirements, such as constant current charging, constant voltage charging, pulse charging, etc., to simulate various charging and discharge environments that the battery may encounter in actual use.

(4) Data analysis and storage: built-in data recording and analysis system automatically collects test data, through the supporting software tools for analysis, users can easily generate historical records, track battery performance changes, and export detailed test reports.

(5) Safety protection: It is equipped with a number of protection mechanisms such as overcharge, overdischarge, short circuit and overheating to ensure the safety of the operator and the equipment itself.

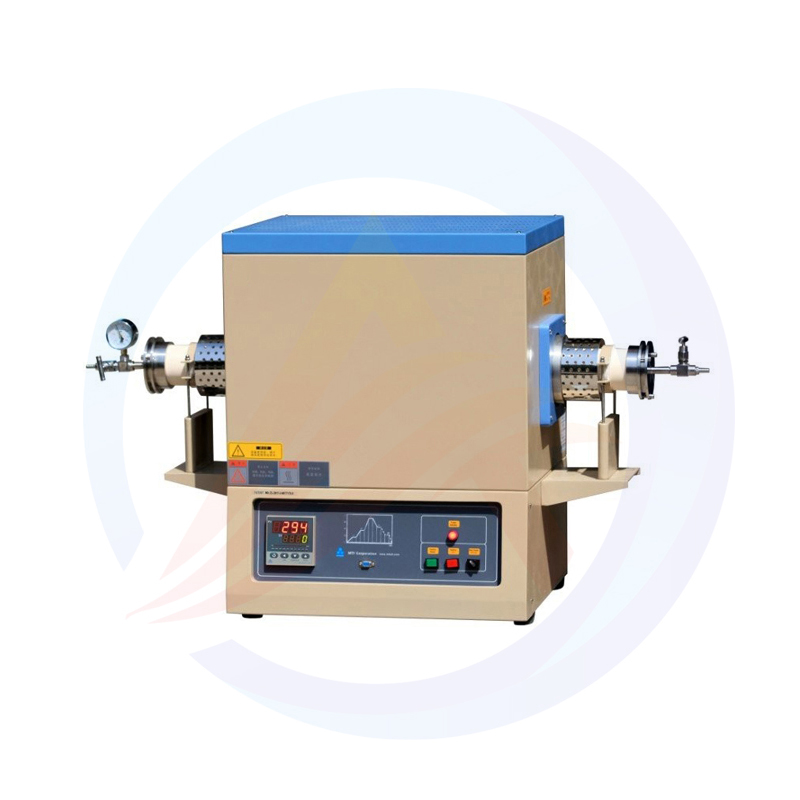

(6) Environmental adaptability: high-quality test machines are designed with good environmental adaptability and can work stably in a wide range of temperature and humidity

4. Operation process of lithium battery testing machine

The operating process of the lithium battery testing machine mainly includes the following steps:

(1) Preparation: First, confirm that the power connection is stable and meets the requirements of the equipment, and connect the power cord of the lithium battery test machine to the appropriate power supply. Next, the lithium battery to be tested is placed on the test table to ensure that it is stable and motionless. Finally, check whether the test device is in good condition, without damage or loosening.

(2) Start and set: Turn on the power switch and start the lithium battery test machine. According to the test requirements, the corresponding parameters are set on the control panel, such as collision speed, collision number, collision Angle (for the crash test machine) or voltage, current, capacity, etc. (for the comprehensive tester).

(3) Start the test: After confirming that the connection is correct and the appropriate test parameters are selected, press the "Start test" button, and the device will test according to the set parameters. During the test process, it is necessary to wait patiently, pay attention to the status of the lithium battery during the test, and record the relevant data.

(4) End and follow-up: When all tests are completed, the equipment will automatically stop. At this point, you can turn off the power and disconnect the test sample from the test machine. According to the test results, the performance of the lithium battery can be assessed if it meets the requirements, and the corresponding treatment or improvement can be carried out accordingly.

5. Application field

Lithium battery testing machine is widely used in the development, production, testing and quality control of lithium batteries. It can not only help engineers analyze and improve battery performance in the battery design stage, but also screen out unqualified batteries in the battery production process to ensure the quality of battery products. In addition, the lithium battery test machine is also used for battery life assessment and later maintenance work to provide support for the long-term stable operation of the battery.

In summary, the lithium battery testing machine is an indispensable and important equipment in the lithium battery industry chain, and its functions and advantages ensure the optimal performance of lithium batteries in practical applications and ensure the safety of the battery. With the continuous development of lithium battery technology and the continuous expansion of application fields, the functions of lithium battery testing machines are also constantly improving to evaluate and guarantee the performance of lithium batteries more comprehensively and accurately.