The specific operation process of each step is as follows:

1. Preparatory work

1) Electrode materials such as active materials, conductive agents, binders, etc. should be dry and stored, and can be used at any time. If there is moisture absorption, it should be dried before use.

2) The collector of the positive active material generally uses an aluminum sheet, and the thickness of the aluminum sheet in the buckle battery is about 0.3mm. The anode material collector is a copper sheet of similar thickness. According to the size of the battery case, the aluminum sheet and the copper sheet are cut or stamped in the same shape, and the tablet press is used to flatten it. The diameter of the electrode sheet is between 12mm-15mm, it is best to keep it consistent, and clean and dry it to keep the surface clean and smooth.

3) Prepare other tools for assembling batteries, such as trays, scissors, tweezers, bullet, clean battery shell, foam nickel, separator, small beaker, needle barrel or plastic head dropper. Note: The size of the nickel foam is similar to the size of the electrode sheet, and the size of the separator is consistent with the inner diameter of the positive battery shell.

4) According to the designed data recording table, carefully weigh the clean electrode sheet and place it in order. (This laboratory adopts the following method to take a clean positive shell and mark it, and the weighed electrode sheet can be stored in it.)

2. Size mixing

The laboratory practice:

1) Accurately weigh the active substance, conductive agent (acetylene black) and binder (PVDF) according to the designed mass ratio (lg).

2) Grind in the agate mortar for about 15 minutes, then transfer to the reagent bottle.

3) Add an appropriate amount of NMP(1L-methyl-2-pyrrolidone), 1g electrode material about 3 plastic head eyedropper NMP. It can be adjusted during operation. Use a small electric mixer and blend for 2-3 hours. The viscosity of the paste can be controlled during this process.

3. Prepare the electrode sheet

1) Dip the glass rod into the slurry and evenly coat the aluminum sheet or copper sheet.

2) Dry in the oven at 60 ° C for 12 hours, if the air humidity is large, it is recommended to transfer to the vacuum oven at 100 ° C for 2-3 hours after initial drying.

3) Quickly remove the electrode sheet and flatten it with a powder tablet press (about 10 MPa).

4) Weigh the quality of the flattened electrode sheet, make a record, and put it in the numbered paper bag.

4. Dry

1) Put the tools and pole pieces prepared during the preparation process into a vacuum oven to dry. Specific items can include: trays, pole pieces, scissors, tweezers, bullet, small beaker, needle or plastic eye dropper, battery case, foam nickel, filter paper, toilet paper. The above items are dried at 10℃ vacuum for 3-5 hours.

2) The separator and sample bag are dried at a relatively low temperature, such as 60 ° C for 8-12 hours.

5. Equipped with button battery

1) Check whether the vacuum glove box is in normal working condition. It is best to control oxygen and water vapor below 1ppm.

2) Transfer the above prepared items into the glove box.

3) Cut or press aluminum sheet in the glove box. The size of the aluminum sheet is best consistent with the size of the electrode sheet.

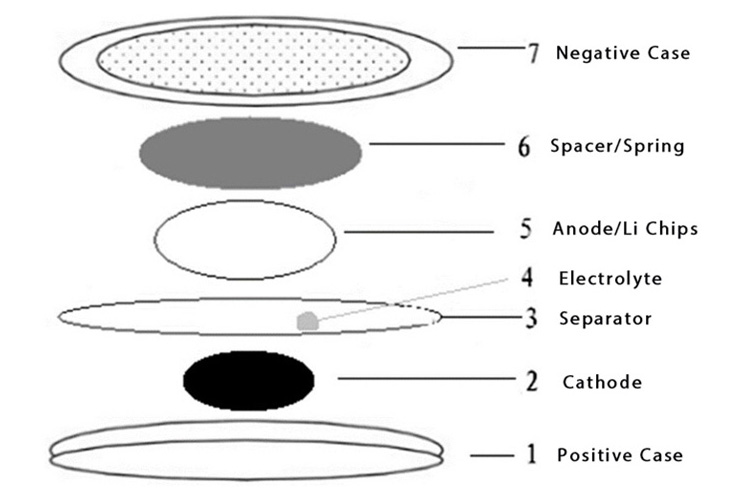

4) Battery assembly, assembly sequence is as follows: positive shell up, put a positive peg piece (facing up), into the separator, into the negative lithium sheet, into the separator, add the appropriate amount of electrolyte, and finally buckle the negative shell (facing down). Pay attention to the positive electrode sheet, separator, lithium chips and foam nickel as far as possible in the center.

5) If the battery sealer is in the glove box, seal the battery directly. If the sealer is outside the glove box, the battery paper bag can be put into the sample bag and sealed.

6) Clean the glove box and take out the items brought in. If the battery case is outside, seal the battery.

7) Stand the battery and prepare for testing.

We not only provide battery machines for coin cell, but also provide all kinds coin cell battery materials!