三、the mixing process of lithium batteries

四、the classification of lithium battery mixer

In today's society, the application of new energy technology in life is becoming more and more extensive, and lithium-ion batteries, as a new type of energy-efficient batteries, have become the darling of modern industry. In the entire production process of lithium battery, the battery mixing machine to the slurry mixing as the first step in the production of lithium ion battery, its impact on product quality of more than 30%, its process level directly affects the safety and consistency of the battery and other performance indicators.

Under the action of mechanical agitation, the suspension is generated and maintained, and the mass transfer between solid and liquid is enhanced. It is usually divided into the following parts:

(1) Suspension of solid particles;

(2) Re-suspension of settling particles;

(3) the suspended particles penetrate into the liquid;

(4) The force between the particles and the paddle is used to disperse the particles and control the size of the particles;

(5) The formation of mass transfer between solid and liquid.

Wetting: The liquid solvent replaces the gas to occupy the surface of the particles to be dispersed.

Dispersion: through the mechanical action of stirring equipment to disperse particles.

Stabilization: The particles that have been dispersed are no longer aggregated together.

三、the mixing process of lithium batteries

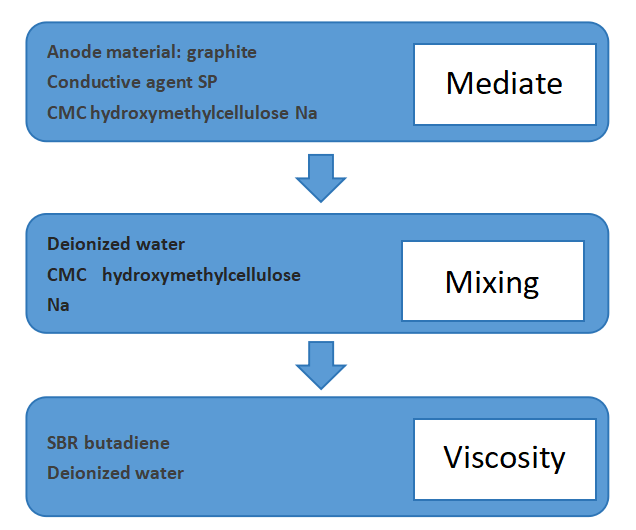

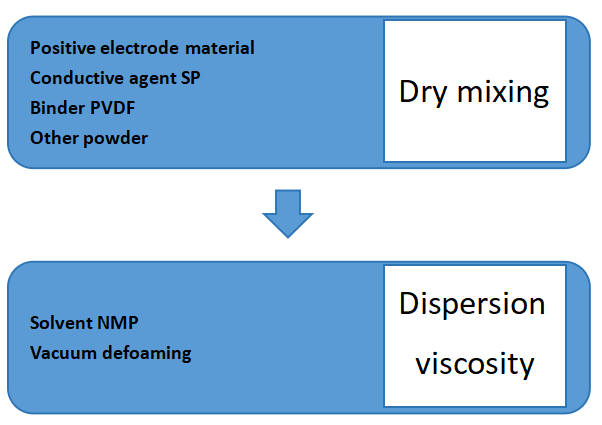

The mixing process of lithium-ion batteries can be roughly divided into two kinds, one is the glue wet mixing process, and the other is the dry mixing process.

Typical anode dry mixing process:

Typical cathode dry mixing process:

四、the classification of lithium battery mixer

(1) Double planetary mixer:

Double planet power mixer is a combination of traditional double planet mixer and high-speed dispersion machine principle, composed of an efficient new model, has a wide range of applications in the field of new energy. In view of the characteristics of lithium battery and capacitive slurry, an enhanced power mixer with high speed and greater torque was developed on the basis of the proto-planetary power mixer, which is suitable for the preparation of lithium battery positive and negative slurry by dry mixing and wet mixing.

Twist paddle clockwise rotation, rotation, while high-speed dispersion from counterclockwise rotation, its speed can be variable frequency speed, so that the slurry to do complex movement, subject to strong cutting, kneading and dispersion effect, 76 to achieve mixing without dead Angle efficient mixing and no "climbing" phenomenon.

In terms of sealing, three sets of mechanical seals plus soft and static seals ensure reliable sealing; In terms of slurry temperature control, the unique temperature measurement technology is used to orbit the planet box with the temperature measuring rod, and the PT100 sensor is used to directly contact the material, making the measurement more accurate, responsive and accurate (the error is only ±1.0℃

(2) Cup vacuum mixer:

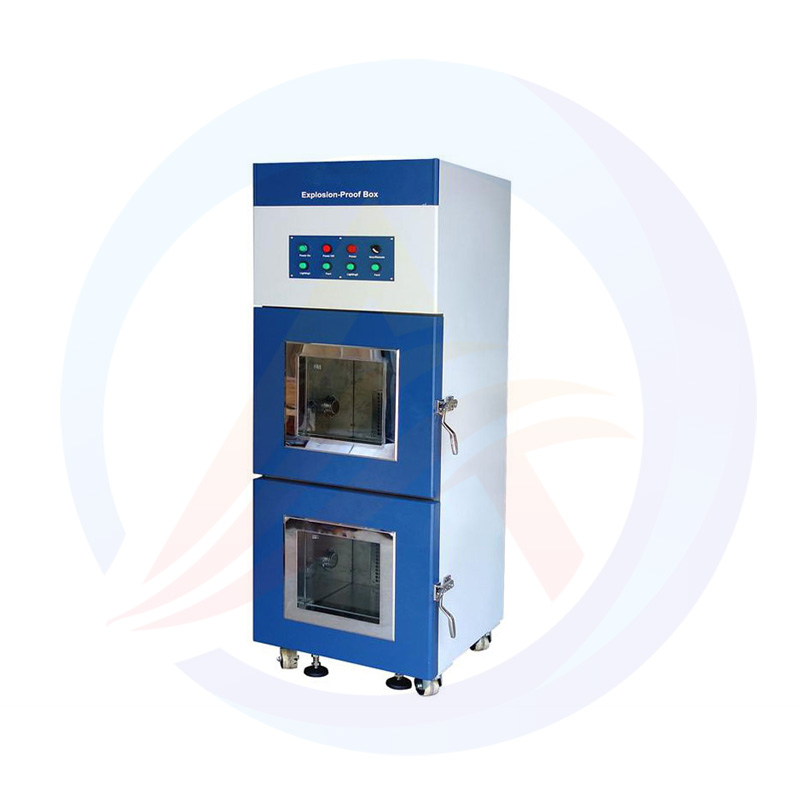

vacuum mixer is a set of vacuum mixing, dispersion as one of the efficient equipment, suitable for the battery experiment process of positive and negative slurry mixing process, as well as powder materials, various ceramics mixing; Because the stirring is done in a vacuum state, it is completely free of bubbles, thus improving the filling of the material and the tightness of the model

Features:

1. The use of industry-leading software sealing process, sealing effect is good.

2. Mixing motor adopts transmission frequency adjustment, which can choose different speed and torque according to different processes and different viscosity.

3. Double dispersion blade design, so that the material up and down and around the churning, so that the slurry mixing fast and uniform.

(3) Small V-type mixer:

the mixing is unique, through mechanical rotation to make the material in the V-type cylinder of different heights do reciprocating turnover, to achieve uniform mixing purpose, with the cylinder no dead Angle, no material accumulation, fast speed, short mixing time characteristics, the cylinder is made of stainless steel.

Features:

1. The mixing cylinder is made of stainless steel

2. No dead corners, no material accumulation, fast speed

3. Short mixing time

4. Adjustable speed, and equipped with digital timer

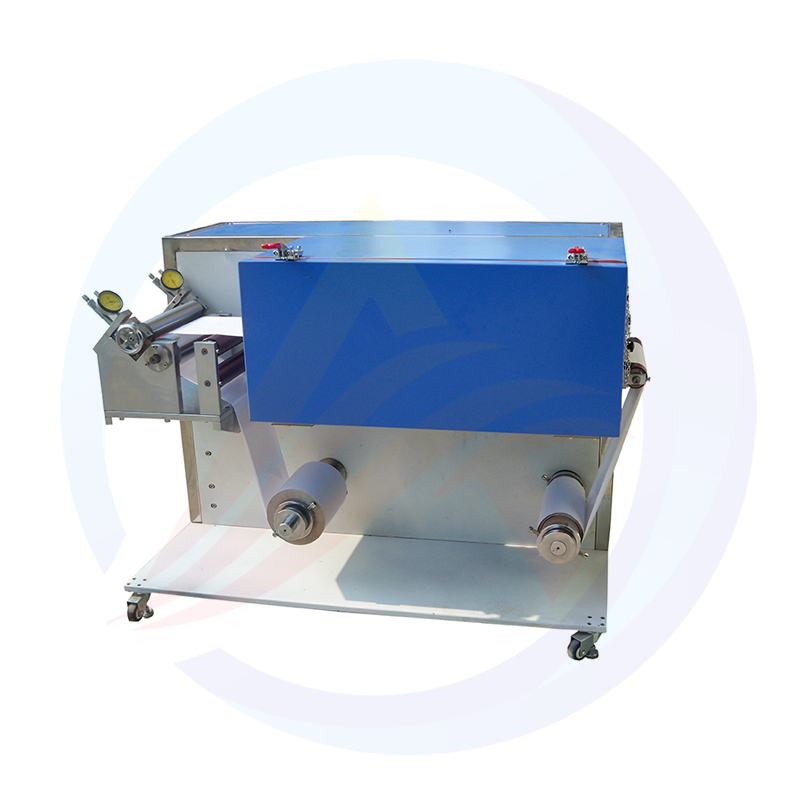

(4) Lithium battery horizontal mixing:

lithium battery cathode material Horizontal mixing equipment is a kind of equipment specially used for mixing lithium ion battery cathode materials, mainly used for the production of various types of lithium ion battery cathode materials, such as ternary materials, lithium cobalt oxide materials, lithium manganese oxide materials, etc. The device mixes raw materials thoroughly through the rotation and flow of the agitator, thereby improving production efficiency and product quality.

Features:

Horizontal design: horizontal design can effectively reduce the height of the equipment, reduce the center of gravity of the equipment, improve the stability and safety of the equipment.

2. Professional mixer: The equipment is equipped with a double-layer spiral mixer, which can produce the flow of up and down, left and right directions to achieve the full mixing of materials.

3. Equipped with heating and cooling system: the equipment is equipped with heating and cooling system, which can control the temperature of the material according to the process requirements to ensure the quality and mixing effect of the material.

4. PLC control system: The equipment adopts PLC control system, which can realize fully automated operation, with automatic metering, feeding, mixing, unloading and other functions, easy operation, reduce manual intervention, improve production efficiency.

5. Compact structure, easy to clean: The equipment is made of stainless steel, compact structure, smooth surface, easy to clean and maintain.