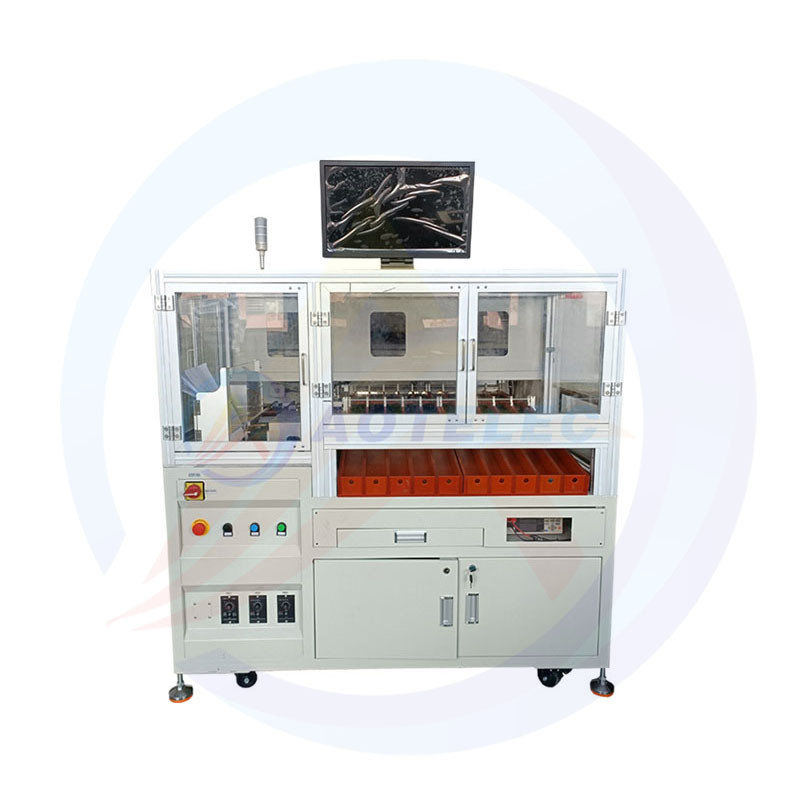

Automatic Protection Board Lithium Battery Pack BMS Testing System

Battery Pack BMS Test Systems

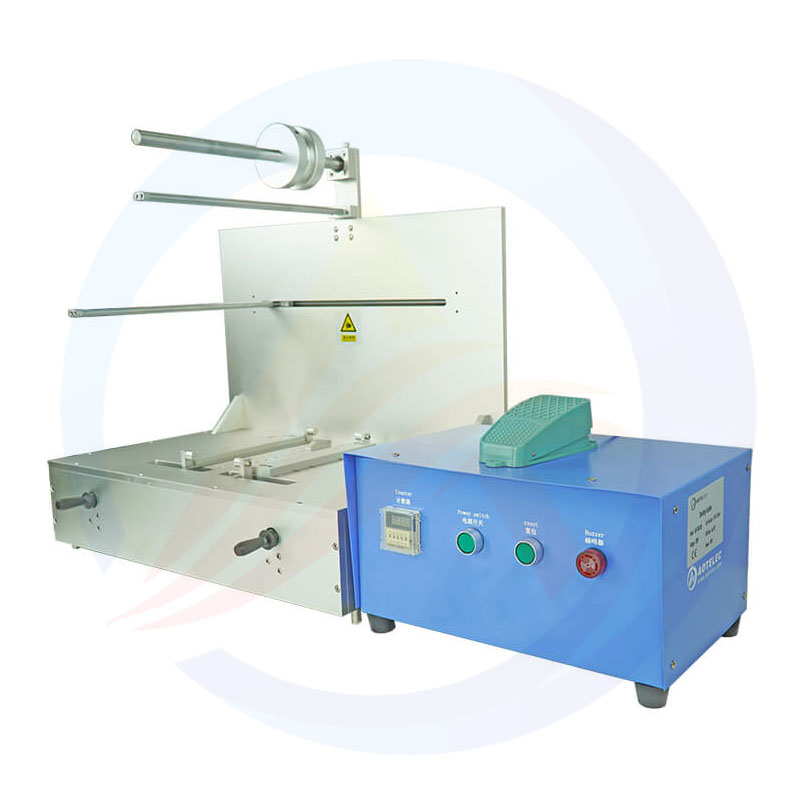

The BMS tester provides quick and precise testing of lithium battery protection board tester. It ensures reliable and efficient evaluation of the battery management system.

The Battery BMS Test Equipment can perform various tests, such as voltage monitoring, current monitoring, temperature monitoring, overcharge protection, over-discharge protection, short circuit protection, and balancing function evaluation.

The BMS Testing Machine is equipped with a user-friendly interface that allows easy operation and navigation. It provides clear and concise instructions for test setup and result interpretation.

Protection Board TesterBMS TesterBMS Testing MachineBattery Pack BMS Test SystemsBattery BMS Test Equipment

Email

More