Voltage Input & Powe | (1)24 VDC input voltage (2)One UL listed 100-240 VAC IN, 24 VDC OUT power adapter is included (3)120W, 24VDC motor |

Rotary Speed | 0 - 600 rpm |

Slurry Viscosity | Max. 10000 mPa·s (cps) @ 600 rpm |

Mixing Containers | (1)One 150 mL stainless steel 304 vacuum-sealed container is included (minimum loading required is 50mL) (2)Dual helical ribbon mixing blades are built on the lid of the container. |

Vacuum Pump | (1)Built-in single-stage vacuum pump (2)Vacuum Level: -0.08 ~ -0.09 MPa |

Control Panel | (1)3.5" color touch screen control allows easy setting of parameters such as mixing speed, mixing time, vacuum on/off Mixing Time: 0 - 600 minutes Mixing Speed: 0 - 600 RPM and 3 segments programmable |

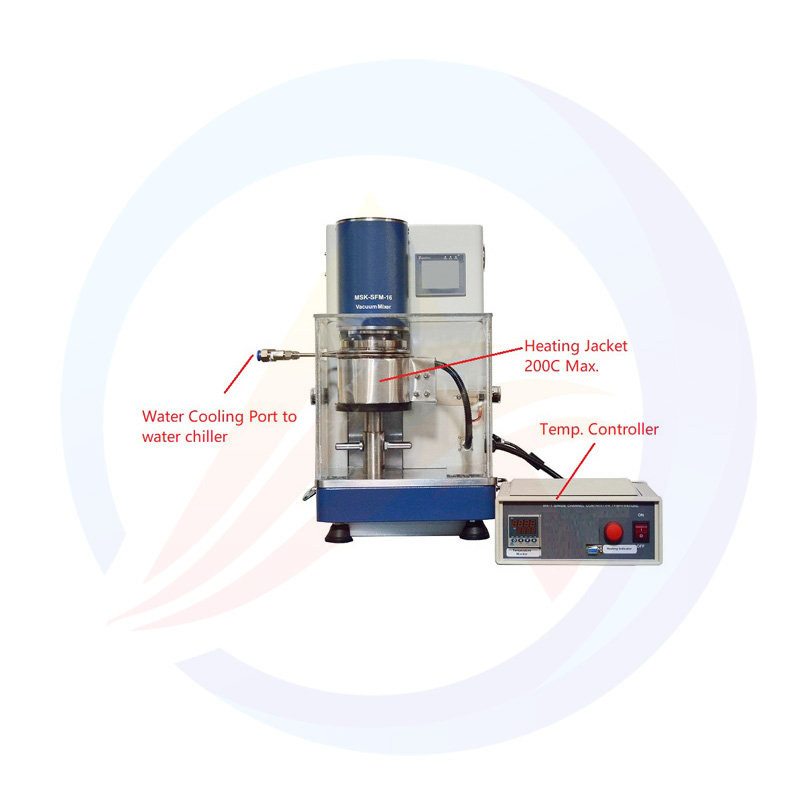

Heating Container with Temp.Control' (Optional) | (1)The heating container is available at an additional cost. Please contact us for a quote. (2)The heating container can be heated up to 200°C with precision temperature control for heated vacuum mixing. (3)The heating option ONLY comes with a 500ml heating container,please contact us if other sizes are needed.

|

Dimensions | 330 mm x 320 mm × 570 mm (L x W x H) |

Shipping Dimensions | 18'' x 18'' x 24'' (L x W x H) |

Net Weight | 70 lbs |

70 lbs | One year limited with lifetime technical support |