1、the basic understanding of lithium battery spot welding machine

2、the role and significance of lithium battery spot welding machine

3、lithium battery spot welding machine operation process

4、the application of lithium battery spot welding machine in lithium battery manufacturing

In the context of today's global energy transition, lithium batteries, as a core component of new energy technologies, are becoming increasingly important. Whether it is electric vehicles, energy storage systems, or all kinds of portable electronic devices, lithium batteries play a pivotal role. In the production and manufacturing process of lithium batteries, Battery Spot Welding Machine, as a key equipment, plays an irreplaceable role in ensuring battery performance, improving production efficiency and ensuring production safety.

1、the basic understanding of lithium battery spot welding machine

1.1 Definition and Functions

Lithium battery spot welding machine is a kind of equipment specially used for precision welding of battery cell, pole, pole ear and other components in the manufacturing process of lithium battery. Through a short and high-intensity current pulse, it rapidly generates high temperature on the contact surface, melting the metal and forming a strong metallurgical bond to achieve an effective connection of the internal components of the battery.

1.2 Working Principle

The working principle of the lithium battery spot welding machine is based on resistance welding technology, that is, the resistance heat generated by the current through the contact surface is used to achieve welding. When the electrode applies pressure to the workpiece and is energized, the tiny bulge on the contact surface is first heated to the melting state, and with the continuous action of the current, the melting area gradually expands and forms a melting core. After power failure, the molten core solidifies during cooling to form a strong welded joint.

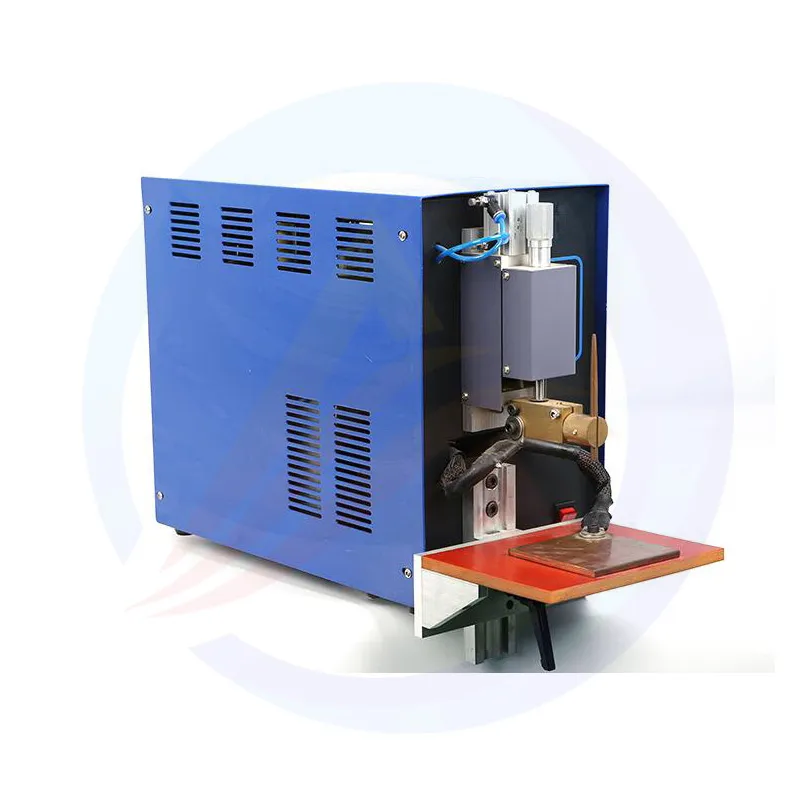

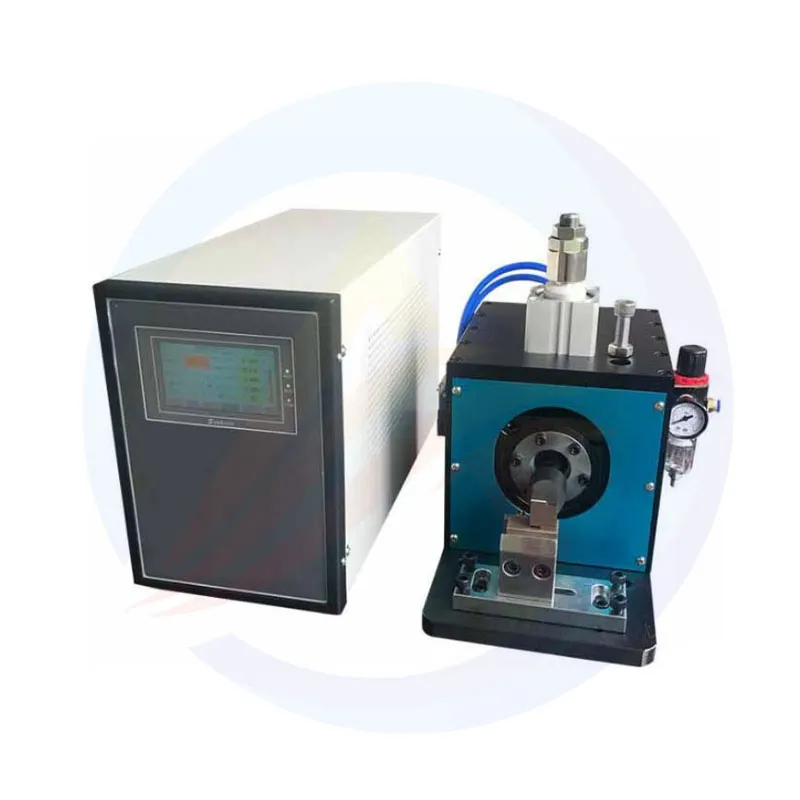

1.3 Device Composition

Lithium battery spot welding machine is mainly composed of welding power supply, control system, electrode device, workbench and pressure system. The welding power supply is responsible for providing stable current output; The control system is used to set and adjust welding parameters; The electrode device is the key component in the welding process, and its material and shape directly affect the welding quality. The table is used to place the workpiece to be welded; The pressure system ensures that the electrode applies the appropriate pressure to the workpiece during welding.

2、the role and significance of lithium battery spot welding machine

2.1 Improve welding quality

In the process of lithium battery manufacturing, welding quality is one of the important indicators to measure the performance of the battery. By precisely controlling welding parameters and electrode pressure, the lithium battery spot welding machine can achieve a high degree of automation and consistency in the welding process, ensuring the strength and reliability of the welded joint, thereby improving the safety and cycle life of the battery.

2.2 Improve production efficiency

Lithium battery spot welding machine adopts automatic operation mode, which can greatly reduce manual intervention and improve welding efficiency. At the same time, its fast welding speed and efficient energy conversion rate make the number of welding per unit time significantly increase, effectively shorten the production cycle, reduce the production cost.

2.3 Ensure production safety

Lithium battery production process involves a large number of flammable and explosive materials, such as electrolyte, lithium metal and so on. Traditional welding methods may cause safety hazards such as sparks and spatter. The lithium battery spot welding machine uses closed welding, which can effectively prevent sparks from splashing, reduce the risk of fire and explosion, and ensure production safety.

3、lithium battery spot welding machine operation process

3.1 Preparations

Equipment inspection: Before using the lithium battery spot welding machine, the equipment should be comprehensively inspected to ensure that all components are intact, tightly connected, and without loosening.

Parameter setting: According to the material, thickness and welding requirements of the workpiece to be welded, reasonably set welding parameters, such as welding current, welding time, electrode pressure, etc.

Workpiece preparation: Pre-treatment of the workpiece to be welded, such as cleaning, removing oxidation layer, etc., to ensure the cleanliness and smoothness of the welding surface. At the same time, the appropriate electrode shape and size are selected according to the welding requirements.

3.2 Device Debugging

No-load test: Before the formal welding, carry out no-load test to check whether the output voltage and current of the welding power supply are stable and whether the control system works normally.

Electrode calibration: Adjust the electrode position to ensure the neutrality and parallelism between the electrode and the workpiece contact surface to avoid deviation or dislocation during welding.

Pressure test: check whether the working pressure of the pressure system is stable, and whether the pressure of the electrode on the workpiece meets the requirements. By adjusting the parameters of the pressure system, it is ensured that the electrode exerts appropriate pressure on the workpiece during the welding process.

3.3 Formal Welding

Place the workpiece: place the pre-processed workpiece on the workbench according to the design requirements to ensure that the relative position and spacing between the workpiece meet the welding requirements. At the same time, the workpiece is fixed with a special fixture or positioning device to prevent the workpiece from moving or deformation during the welding process.

Start welding: Press the start button, the welding power supply begins to work, and the electrode applies pressure and current to the workpiece for welding. During the welding process, the welding situation should be closely observed, and the welding parameters and electrode position should be adjusted in time to ensure the welding quality.

Welding completion: After welding, turn off the welding power and wait for the workpiece to cool down. Check the appearance quality of welded joints, such as whether the weld is smooth, no cracks, no slag inclusion, etc. If necessary, further testing and analysis can be carried out using specialized tools or equipment.

4、the application of lithium battery spot welding machine in lithium battery manufacturing

4.1 Cylindrical battery manufacturing

In the process of cylindrical battery manufacturing, lithium battery spot welding machine is widely used in the welding of cell and pole and pole ear. By precisely controlling the welding parameters and electrode shape, the solid connection between the cell and the pole and the pole ear can be realized. At the same time, due to the structural characteristics of cylindrical batteries, the strength and reliability of welded joints are required. Therefore, in the manufacture of cylindrical batteries, lithium battery spot welding machine plays a crucial role.

4.2 Soft-pack battery manufacturing

Soft pack batteries are widely used in portable electronic devices because of their thin and flexible features. In the manufacturing process of soft pack batteries, lithium battery spot welding machine also plays an important role. Due to the structure and material characteristics of the flexible battery, the strength and precision of the welded joint are required. By using a specially designed electrode and welding process, the lithium battery spot welder can achieve precise welding of the soft pack battery pole ears to ensure the safety and reliability of the battery.

5、Conclusion

Lithium battery spot welding machine as one of the key equipment in the manufacturing process of lithium battery, its performance and quality are directly related to the safety, reliability and cycle life of the battery. Through in-depth understanding of the definition, working principle, operating process and its application and development trend in lithium battery manufacturing, we can better understand the importance and value of this equipment. In the future, with the continuous development of the new energy industry and technological innovation, lithium battery spot welding machine will play a more important role in promoting the progress of lithium battery technology and industrial upgrading.