New energy lithium battery laser welding machine

1、the core advantages of laser welding technology

2、the key components of laser welding machine

3、the advantages of welding machine

4、laser welding machine in the application of new energy lithium batteries

1、the core advantages of laser welding technology

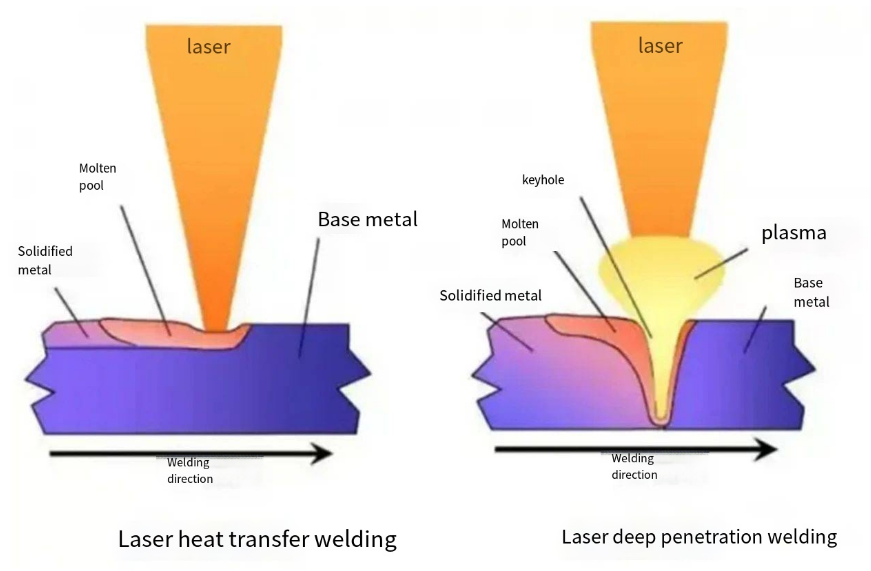

battery Laser welding machine uses a high energy laser beam as a heat source, with high precision, high speed, low thermal impact and other characteristics to achieve precise control of the weld, reduce thermal damage, so as to ensure the safety and performance of the battery.

2、the key components of laser welding machine

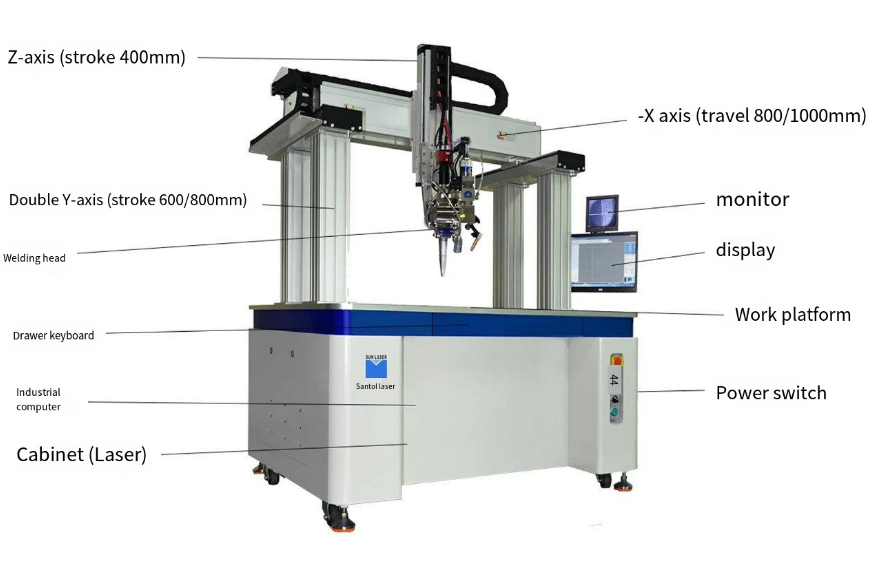

Laser generator: The core component that produces a high energy laser beam, and its quality and performance directly affect the welding effect.

Optical system: responsible for transmitting the laser beam to the working area, ensuring the focus and stability of the beam.

Control system: realize the automation and intelligence of the welding process to ensure the accuracy and consistency of welding.

3、the advantages of welding machine

(1) High efficiency and stability: The use of resistance welding technology to achieve rapid and stable welding, significantly improve production efficiency.

(2) Wide applicability: Flexible response to various lithium battery sizes and shapes, adjustable electrodes to meet diverse needs.

(3) Easy operation: automatic control, intuitive and simple operation, reduce human error, ensure welding quality.

(4) Convenient maintenance: compact design, easy daily maintenance and quick repair, reduce maintenance costs.

(5) Safe and worry-free: low voltage and current operation, combined with multiple protection mechanisms to ensure safe operation and reliable equipment.

(6) Economic efficiency: improve production efficiency and product quality, reduce waste, and help enterprises maximize economic benefits.

4、laser welding machine in the application of new energy lithium batteries

The application of laser welding machinein the field of new energy lithium batteries is leading the innovation and leap of manufacturing process. The introduction of this technology has not only profoundly changed the production method of lithium batteries, but also greatly improved the overall performance and production efficiency of the product, and injected a strong impetus for the vigorous development of the new energy industry.

First of all, the laser welding machine, with its unparalleled high precision, realizes the fine processing of the internal structure of the lithium battery. The micron-scale laser beam accurately penetrates and connects key components such as positive and negative battery materials, explosion-proof valves, housings and modules, ensuring the highest quality of welded joints. This high-precision welding method effectively avoids problems such as virtual welding and missing welding that may occur in traditional welding methods, thus improving the safety and reliability of lithium batteries.

Secondly, the non-contact welding characteristics of the laser welding machine have brought many advantages to the manufacturing of lithium batteries. During the welding process, the laser beam does not need to contact the workpiece surface directly, thus avoiding the damage caused by mechanical pressure on the material. This contactless welding method not only protects the fine structure inside the lithium battery, but also reduces the thermal stress generated during the welding process, further improving the cycle life and overall performance of the battery.