1, lithium battery roll machine: definition and overview

2, the significance of the roller machine

3, lithium battery to roll machine operation process

4,Future development trend and prospect

In the context of global energy transformation and sustainable development, lithium battery as a core component in the field of new energy, its performance and production efficiency are directly related to the healthy development of electric vehicles, energy storage systems and even the entire green economic chain. In this wave of technological innovation, the lithium battery roller machine as a key production equipment, with its unique process advantages and efficient production capacity, has become an important force to promote the upgrading of the lithium battery industry.

1, lithium battery roller press machine: definition and overview

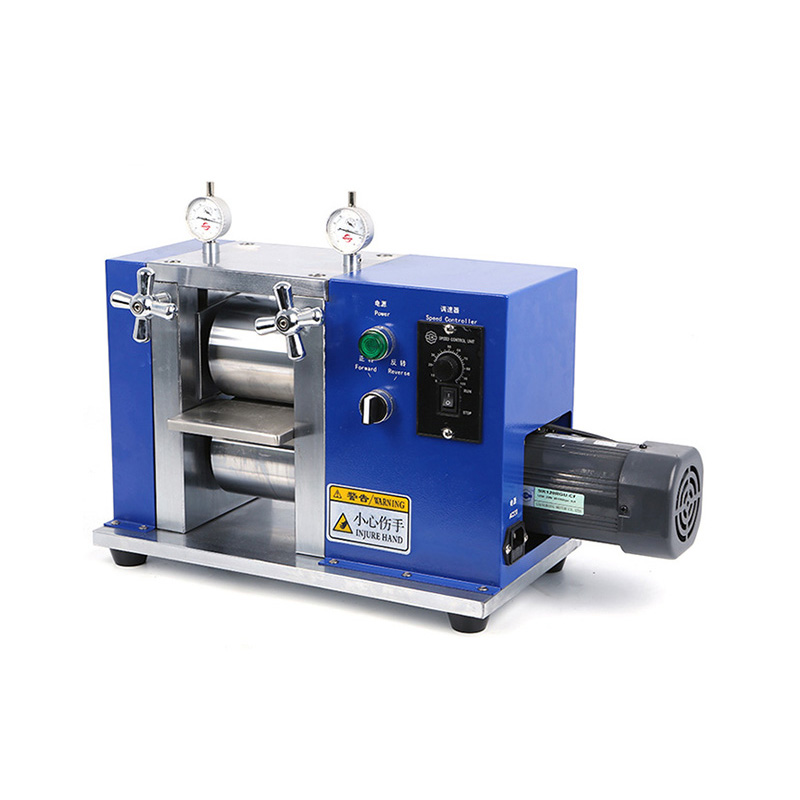

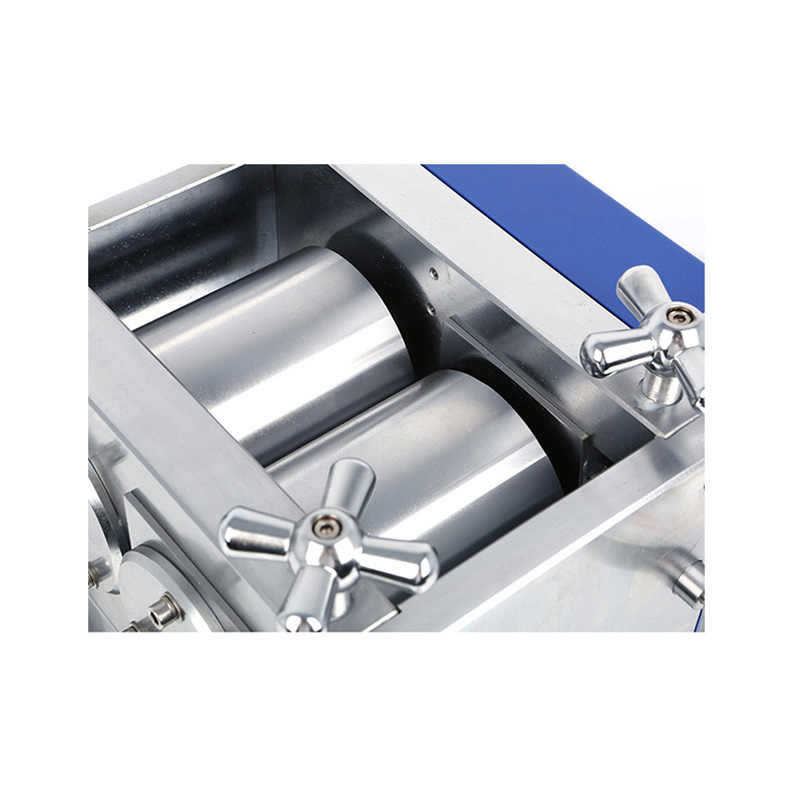

Lithium battery rolling press machine, as the name suggests, is a roller molding equipment specially used in the production of lithium batteries. It makes the material achieve ideal density and thickness uniformity through high-precision roller processing of positive and negative electrode materials, thereby improving the energy density, cycle life and safety performance of the battery. Lithium battery roller press machine is usually composed of two high-precision roller wheels, by adjusting the roller gap, pressure and speed parameters, to achieve accurate control of the material. In addition, the modern lithium battery roller machine also integrates automation and intelligent technology, which realizes the monitoring and adjustment of the whole process from the material to the finished product, greatly improving the production efficiency and product consistency.

2, the significance of the roller machine

2.1 Improving Battery Performance

By accurately rolling positive and negative electrode materials, the roller can effectively improve the pore structure of the material, reduce the porosity, and increase the volume energy density of the material. At the same time, the rolling process can also promote the close contact between the active substance and the collector, reduce the internal resistance, and improve the charge and discharge efficiency and cycle stability of the battery. These performance improvements have directly promoted the expansion of lithium batteries in electric vehicles, portable electronic equipment and other fields.

2.2 Improve production efficiency

The automated, intelligent lithium battery roller can achieve continuous and stable production operations, greatly reducing manual intervention and downtime. In addition, by precisely controlling the rolling parameters, multiple processes can be completed at one time, such as coating, drying, rolling, etc., effectively shortening the production cycle and improving the overall production efficiency. This is of great significance for reducing production costs and enhancing market competitiveness.

2.3 Promoting industrial upgrading

The wide application of lithium batteries to rollers not only promotes the continuous progress of lithium battery manufacturing technology, but also promotes the upgrading and integration of the entire industry chain. On the one hand, the innovation and development of roller technology has driven the technological innovation and product upgrading of upstream material suppliers; On the other hand, efficient and stable lithium battery production also provides more high-quality and reliable energy solutions for the downstream application market, and accelerates the rapid development of emerging industries such as new energy vehicles and energy storage systems.

3, lithium battery to roller press machine operation process

3.1 Preliminary Preparations

Material preparation: Ensure the quality of positive and negative electrode materials, fluid collectors and other raw materials, and pre-treat according to process requirements.

Equipment inspection: check whether all parts of the roller machine are in good condition, whether the surface of the roller wheel is clean and smooth, and adjust the gap of the roller wheel to the set value.

Parameter setting: According to product requirements, set roller pressure, speed, temperature and other key parameters.

3.2 Production Process

Material feeding: Place the pre-treated positive and negative electrode material on the feeding device, start the feeding system, so that the material is uniformly and continuously fed into the rolling machine.

Roll forming: The material is subjected to uniform pressure between the upper and lower rollers, and plastic deformation occurs to form a pole sheet with a certain thickness and density.

Online monitoring: The sensor is used to monitor the pressure, temperature, speed and other parameters in the rolling process in real time to ensure that the production process is stable and controllable.

Finished product blanking: the pole sheet after rolling is cut, split and other subsequent processing to form a finished product, and automatically transported to the next process or finished product warehouse.

3.3 Later Maintenance

Equipment cleaning: regularly clean roller, feeding device and other parts to prevent impurities residue affecting product quality.

Maintenance: Check the wear of each component of the equipment, and replace the damaged parts in time to ensure the long-term stable operation of the equipment.

Data analysis: Collect various data in the production process and carry out statistical analysis to provide basis for optimizing the production process and improving product quality.

4. Future development trend and prospect

With the rapid development of new energy vehicles, energy storage systems and other fields, the requirements for lithium battery performance and production efficiency will continue to increase. As a key production equipment, the technological innovation and upgrading of the lithium battery roller machine will be an important driving force for the sustainable development of the lithium battery industry. In the future, the development of lithium batteries on rollers will show the following trends:

(1) High precision and high automation: With the continuous progress of intelligent manufacturing technology, lithium battery roller will pay more attention to the improvement of precision control and automation level to achieve higher efficiency and higher quality production.

(2) Intelligent management: Through the integration of advanced technologies such as the Internet of Things, big data and artificial intelligence, remote monitoring, fault diagnosis and predictive maintenance of the roller machine are realized, and the intelligent level of production management is improved.

(3) Green environmental protection: In the pursuit of efficient production at the same time, lithium battery roller will pay more attention to the improvement of environmental performance, the use of more environmentally friendly materials and processes, reduce energy consumption and pollution emissions in the production process.

(4) Customized services: for different customer needs and application scenarios, to provide customized lithium battery roller solutions to meet the diversified needs of the market.