一、Green transformation of lithium battery industry

二、Technical advantages of battery tube furnace

三、Lithium battery production of green intelligent journey

四、Deep integration of intelligence and digitalization

五、Market outlook and future outlook

In today's wave of global energy transformation and green development, lithium batteries, as an important part of the field of new energy, are experiencing unprecedented technological innovation and industrial

up grading. Among them, the battery tube furnace as a key equipment in the production process of lithium batteries, with its unique technological advantages and high efficiency, is gradually becoming an

important force to promote the green and intelligent transformation of the lithium battery industry. This paper will deeply discuss the application of battery tube furnace in the production of

lithium battery and the technical innovation and market prospect behind it.

一、Green transformation of lithium battery industry

With the global emphasis on environmental protection and sustainable development, countries have introduced policies to encourage the development of new energy industry,

lithium batteries as a key component in electric vehicles,

energy storage systems and other fields, its market demand has shown explosive growth. However, there are problems such as high energy consumption and pollution in

the production process of traditional lithium batteries, which seriously restricts the sustainable development of the industry. Therefore, how to achieve the green manufacturing

of lithium batteries has become animportant issue that needs to be solved in the industry.In this context, many enterprises began to explore the green transformation of lithium battery production, of which Zhejiang Tianneng New Energy (Huzhou) Co., LTD.

(hereinafter referred to as "Huzhou Lithium") one of the best. By introducing advanced battery tube furnaces and other equipment, Huzhou Lithium battery has realized the comprehensive upgrade of lithium battery production from semi-automation to full

automation and then to digitalization, which not only greatly improves production efficiency, but also significantly reduces energy consumption and pollution, setting a benchmark for the green transformation of

the lithium battery industry.

二、Technical advantages of battery tube furnace

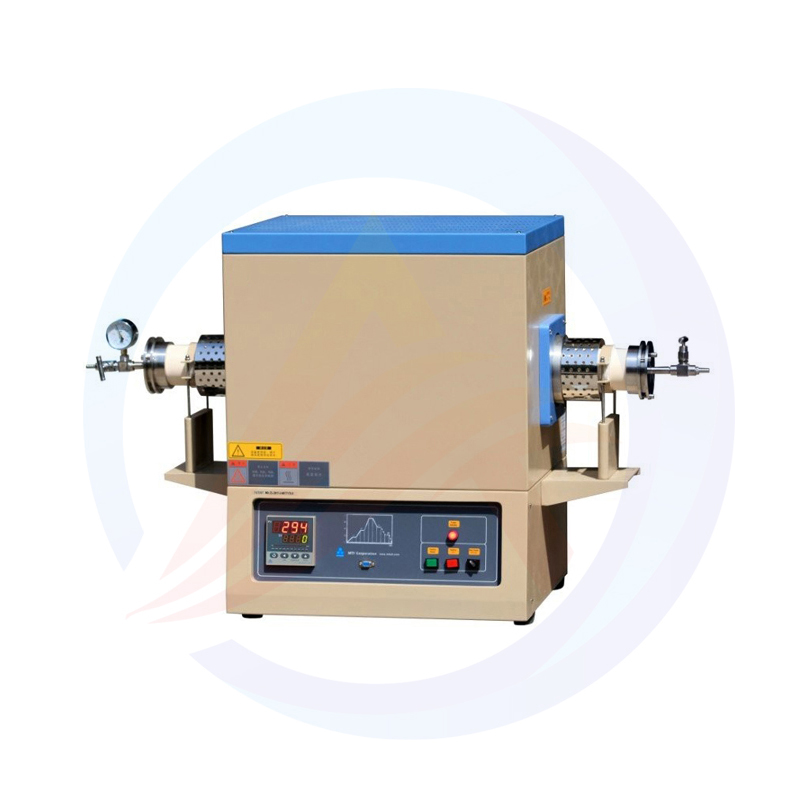

Battery tube furnace, as an important equipment in the preparation of anode and cathode materials for lithium battery, has many advantages such as mature technology, simple operation and high temperature

control accuracy. It is mainly used in the pre-decomposition and roasting process of lithium anode and cathode materials, through the precise control of the temperature, atmosphere

and other conditions in the furnace, so that the raw materials in the best state of the biochemical reaction, so as to prepare excellent performance electrode materials.

In the production workshop of Huzhou lithium battery, the reporter witnessed the efficient operation of the battery tube furnace. I saw rows of tube furnaces arranged neatly, the flames in the furnace were raging,

and the positive and negative electrode materials underwent complex physical and chemical changes in the furnace. According to Xie Mo, deputy general manager of Huzhou Lithium Electric, these tube furnaces

use internationally advanced energy-saving technology and intelligent control system, which can monitor the temperature, atmosphere and other parameters in the furnace in real time, and make accurate

adjustments according to production needs to ensure the preparation quality of electrode materials.

三、Lithium battery production of green intelligent journey

The birth of a lithium battery needs to go through a number of complex processes such as mixing, coating, rolling, cutting, producing, winding (or laminating), liquid injection, packaging, formation and so on.

The role of battery tube furnace is mainly reflected in the pre-decomposition and roasting of positive and negative electrode materials.

In the process of preparing positive electrode materials, the battery tube furnace can decompose and oxidize raw materials such as lithium iron phosphate at high temperatures by precisely controlling the

temperature and atmosphere in the furnace, and form positive active substances with excellent electrochemical properties. At the same time, the atmosphere control in the furnace can also effectively avoid the

introduction of impurity elements and improve the purity of the positive electrode material. The cathode material treated by tube furnace not only has stable performance, but also has a long cycle life.

The preparation of the anode material is also inseparable from the help of the battery tube furnace. In the process of pre-decomposition and roasting of anode materials, the tube furnace makes raw materials such

as lithium metal REDOX reaction by precisely controlling the temperature and atmosphere conditions in the furnace, and forms negative active substances with good electrical conductivity and lithium storage

properties. These negative active substances will play a key role in the subsequent cell synthesis process.

四、Deep integration of intelligence and digitalization

With the rapid development of intelligent manufacturing and digital technology, Huzhou lithium Battery has also realized the deep integration of intelligence and digitalization in the production process of lithium

batteries. In the operation process of key equipment such as battery tube furnace, the intelligent control system precisely controls the temperature, atmosphere and other parameters in the furnace through

real-time collection and analysis of production data to ensure the preparation quality of electrode materials. At the same time, the construction of digital factories also provides strong

support for the visualization and traceability of the production process.

In the production workshop of Huzhou lithium Battery, a prominent blue "digital factory" large screen came into view. The above displays the data parameters of battery production such as material quantity, pass

rate of each process, test pass rate, ambient temperature, humidity, and energy consumption in real time. Through these data parameters, production managers can grasp the production status in real time, discover

and solve problems in time, and ensure the smooth progress of the production process.

五、Market outlook and future outlook

With the rapid development of the global new energy industry and the continuous expansion of the electric vehicle market, the market demand for lithium batteries will continue to grow. The battery tube furnace

as one of the key equipment in the production process of lithium batteries, its market prospects will also be very broad. In the future, with the continuous progress of technology and the further reduction of costs,

battery tube furnaces will play a more important role in the production of lithium batteries.

At the same time, with the continuous application and promotion of intelligent manufacturing and digital technology, lithium battery production will develop in a more intelligent and green direction. The active

exploration and practice of Huzhou lithium Battery and other enterprises in this field has not only set a benchmark and a model for the industry, but also contributed China's wisdom and strength to the sustainable

development of the global new energy industry.