What is the vacuum drying machine?

A vacuum drying machine, also known as a vacuum dryer, is a specialized equipment used for drying materials under reduced pressure or vacuum conditions. It operates by creating a vacuum environment, which lowers the boiling point of water or other solvents present in the materials, facilitating rapid evaporation and drying.

The vacuum drying machine works by creating a vacuum environment inside a sealed chamber or drying vessel. By reducing the pressure inside the chamber, the boiling point of the liquid lowers, allowing it to evaporate at a lower temperature. This mechanism enables gentle drying of heat-sensitive materials, as lower temperatures can be used compared to traditional drying methods.

The vacuum drying machine typically consists of the following components:

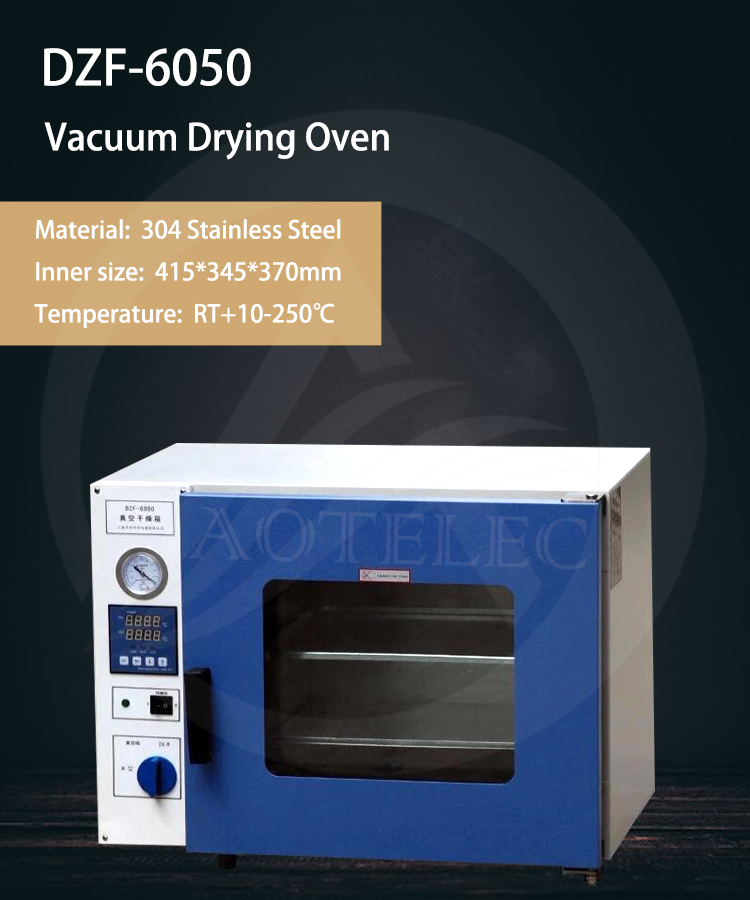

1. Drying Chamber: The main vessel or chamber where the material to be dried is placed. It is usually made of stainless steel to maintain cleanliness and prevent contamination.

2. Vacuum System: A system that creates and maintains the required level of vacuum inside the drying chamber. It typically includes vacuum pumps, valves, and controls to regulate pressure.

3. Heating System: Heat is applied to the drying chamber to facilitate the evaporation of moisture. Common heating methods include hot water, steam, or electric heating.

4. Condenser: This component is responsible for condensing the evaporated moisture or solvent, converting it back into a liquid form. It helps maintain the vacuum inside the chamber and prevents the release of vapors into the environment.

5. Control System: A control panel or computerized system that regulates and monitors the temperature, pressure, and drying time. It ensures precise control and optimization of the drying process.

The vacuum drying machine offers numerous advantages, including faster drying times, reduced energy consumption, preservation of product quality, and the ability to dry heat-sensitive or delicate materials. It is widely used in industries where low-temperature drying and solvent removal are critical.

The application of a vacuum drying machine can be found in various industries and processes where moisture removal is critical. Some common applications include:

1. Pharmaceutical Industry: Vacuum drying machines are extensively used in the pharmaceutical industry to dry heat-sensitive materials, such as powders, granules, and pharmaceutical intermediates. It helps preserve the quality, stability, and efficacy of the final drug products.

2. Food Industry: Vacuum drying machines are employed to remove moisture from food products, such as fruits, vegetables, herbs, and spices. This helps extend their shelf life by preventing spoilage, mold growth, and degradation of flavor, color, and nutritional value.

3. Chemical Industry: Vacuum drying machines find application in the chemical industry for drying various chemical compounds, catalysts, polymers, and intermediates. Vacuum drying prevents oxidation, degradation, or decomposition of sensitive chemicals during the drying process.

4. Biotechnology and Life Sciences: Vacuum drying is commonly used in the biotechnology and life sciences field for drying biological samples, freeze-dried vaccines, enzymes, DNA, and other lab-scale or production-scale biopharmaceutical products.

5. Electronics Industry: Vacuum drying machines are utilized in the electronics industry for drying sensitive electronic components, circuit boards, or devices that require low moisture content to prevent damage or malfunction caused by moisture.

6. Materials Science and Research: Vacuum drying machines are used in research laboratories and materials science applications for drying sensitive materials, such as powders, ceramics, composites, and films, under controlled conditions.

Overall, the vacuum drying machine provides a precise and controlled drying environment, allowing efficient moisture removal from various materials while minimizing the risk of thermal degradation or contamination.