The application of ball mill in lithium batteries

Ball milling is a commonly used method in the preparation of electrode materials for lithium-ion batteries. It is especially suitable for the production of cathode materials, such as lithium iron phosphate (LiFePO4), lithium nickel cobalt aluminum oxide (NCA), and lithium nickel manganese cobalt oxide (NMC).

The ball milling process involves grinding and mixing the active materials with conductive additives and binders to form a homogenous mixture. The milling is typically performed in a planetary ball mill, where the grinding jars rotate around their own axis while also rotating around a central axis. The collision and friction between the milling balls and the powder mixture facilitate the mechanical alloying and reduction of particle size.

The application of ball milling in lithium batteries has several advantages:

1. Particle Size Control:

Ball milling allows for precise control over the particle size distribution of the electrode materials. By adjusting the milling time, milling speed, and ball-to-powder ratio, the desired particle size can be achieved, which is crucial for optimizing the battery performance.

2. Homogeneity:

Ball milling ensures a uniform distribution of active materials, conductive additives, and binders within the electrode mixture. This promotes the electrochemical reactions and enhances the overall performance of the battery.

3. Enhanced Electrochemical Activity:

The high-energy milling process can induce structural defects and promote solid-state reactions in the electrode materials, leading to improved electrochemical activity and higher capacity.

4. Improved Electrode-Electrolyte Interface:

Ball milling can improve the interfacial compatibility between the electrode materials and the electrolyte. The mechanical forces during milling can create rough surfaces and increase the contact area between the electrode and the electrolyte, enhancing ion diffusion and reducing interface resistance.

Control points in the ball milling process include:

1. Milling Parameters:

The milling time, milling speed, and ball-to-powder ratio need to be carefully optimized to achieve the desired particle size and homogeneity. These parameters can be adjusted based on the specific electrode material and the targeted battery performance.

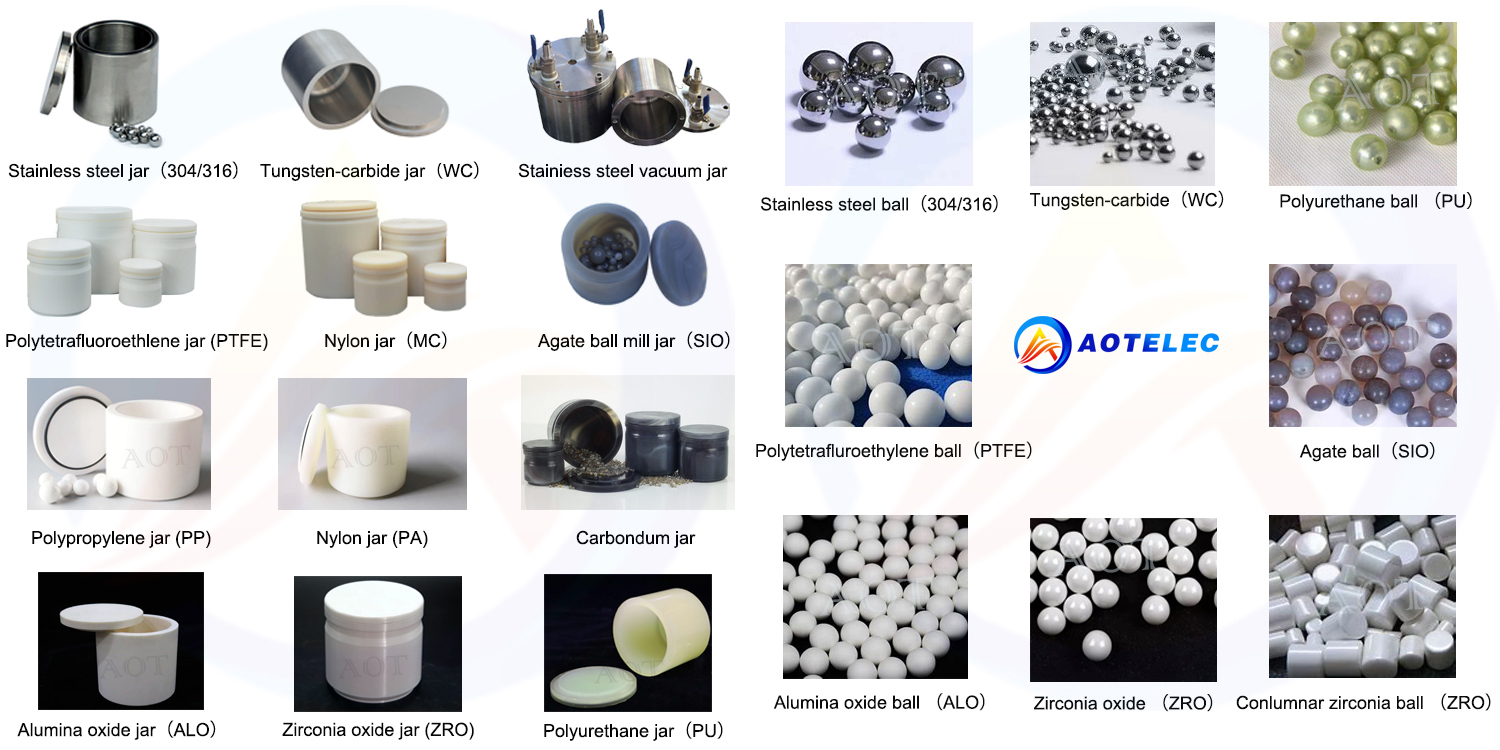

2. Ball Size and Material:

The choice of milling balls, their size, and material composition can affect the milling efficiency and the resulting particle size distribution. Hard and inert balls, such as stainless steel balls or zirconia balls, are commonly used.

3. Moisture and Oxygen Control:

Special attention should be given to preventing moisture and oxygen contamination during the milling process, as they can degrade the electrode materials and affect the battery performance. Grinding in an inert or oxygen-free environment is often preferred.

4. Post-Treatment:

After milling, post-treatment steps like drying, sieving, and mixing with other components (e.g., conductive additives and binders) may be required to complete the electrode preparation.

It's worth noting that the specific details of the ball milling process can vary depending on the electrode material, desired particle size, and other factors. Therefore, it is important to consider the specific requirements of the battery system and consult scientific literature or experts in the field for detailed guidance.