In today's rapidly developing new energy industry, lithium batteries, with their high energy density, long cycle life and environmental protection characteristics, have become an indispensable energy source in electric vehicles, energy storage systems, portable electronic devices and other fields. However, the performance and safety of lithium batteries are directly related to the user experience and market acceptance of the end product, so it is particularly important to conduct comprehensive and accurate testing of lithium batteries.

1, the basic overview of lithium battery testing machine

Lithium battery testing machine, as the name suggests, is used for lithium battery performance testing of professional equipment. It can simulate various working conditions of lithium batteries in actual use, such as charge and discharge cycle, temperature change, overcharge and overdischarge protection, etc., so as to evaluate the capacity, internal resistance, cycle life, safety and other key indicators of lithium batteries. With the progress of technology, modern lithium battery testing machines have been highly automated and intelligent, which can realize real-time data acquisition, analysis and report generation, greatly improving the test efficiency and accuracy.

2, the main function of lithium battery testing machine

Capacity test: By setting specific charge and discharge procedures, the test machine can accurately measure the rated capacity and actual available capacity of the lithium battery, and evaluate the energy storage capacity of the battery.

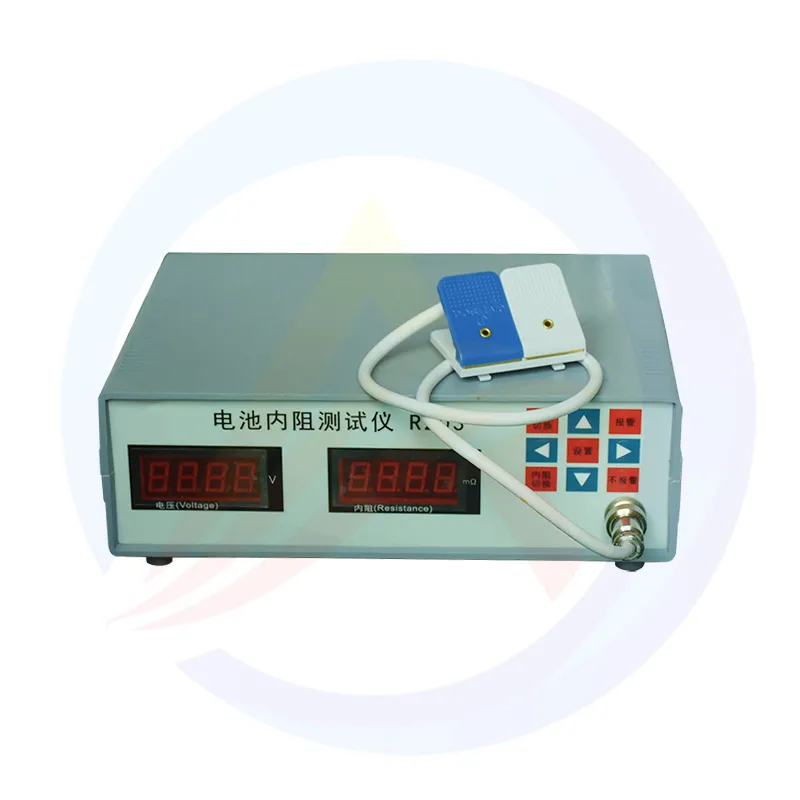

Internal resistance test: Internal resistance is one of the important indicators to measure the performance of lithium batteries, which directly affects the discharge efficiency and heating of the battery. The tester can measure the internal resistance of the battery by DC discharge method or AC impedance method to help identify abnormal conditions inside the battery.

Cycle life test: By simulating the repeated charge and discharge process of lithium batteries in practical applications, the test machine can assess the cycle life of the battery, that is, the number of charge and discharge cycles that the battery can withstand under a certain level of performance.

Safety test: including overcharge, overdischarge, short circuit, acupuncture, extrusion and other extreme conditions of the test, designed to verify the lithium battery in abnormal conditions of the safety performance, to prevent the battery thermal runaway, explosion and other safety accidents.

Temperature characteristics test: Test the performance changes of lithium batteries at different ambient temperatures to evaluate the thermal management efficiency of the battery and its adaptability to temperature fluctuations.

Data analysis and reporting: The test machine can automatically collect test data, perform statistical analysis, and generate detailed test reports to provide scientific basis for R&D personnel and guide battery design and optimization.

3, lithium battery testing machine in the development stage of the application

In the development process of lithium batteries, the test machine plays a crucial role. It is not only an important tool to verify the effectiveness of new materials and new processes, but also a key means to optimize battery design and improve battery performance.

Material screening: By testing the combined effect of different positive and negative electrode materials, electrolyte, diaphragm and other key components, the test machine helps developers quickly screen out the optimal material formula, improve the energy density, cycle life and other key performance of the battery.

Design verification: In the battery structure design stage, the test machine can be used to verify the layout of the battery pack, heat dissipation design, and the effectiveness of the protection circuit to ensure the safety and reliability of the battery system in practical applications.

Performance optimization: Based on the test data, researchers can fine-tune the structural parameters and electrochemical parameters of the battery to achieve continuous optimization of the battery performance.

4. The role of lithium battery testing machine in production quality control

In the production process of lithium batteries, quality control is a key link to ensure that each battery can meet the design requirements and meet the market demand. The application of lithium battery testing machine at this stage is mainly reflected in the following aspects:

Incoming material inspection: Perform performance tests on raw materials to ensure that all materials entering the production line meet quality standards and control product quality from the source.

Process monitoring: Set test points in key links of the production line, monitor the production status of the battery in real time, discover and solve abnormal problems in the production process in time, and improve production efficiency and yield.

Finished product testing: Comprehensive performance testing of all finished batteries to ensure that each battery can meet customer performance requirements and safety standards to enhance product competitiveness.

5, the development trend and challenge of lithium battery testing machine

With the rapid development of new energy vehicles and energy storage markets, the performance requirements for lithium batteries are increasing, which puts higher requirements on lithium battery testing machines. In the future, lithium battery testing machines will develop in the following directions:

High precision and high efficiency: With the continuous progress of battery technology, the requirements for test accuracy and efficiency are getting higher and higher. Future test machines will use more advanced sensors and algorithms to achieve higher accuracy and faster test speeds.

Intelligent and networking: Through the integration of the Internet of Things, big data, artificial intelligence and other technologies, the test machine will achieve remote monitoring, intelligent diagnosis and predictive maintenance, and improve the automation and intelligent level of the test process.

Multi-function and customization: For different application scenarios and customer needs, the test machine will provide more abundant test functions and more flexible customized services to meet the diversified development needs of the lithium battery industry.

However, the development of lithium battery testing machine is also facing many challenges, such as the unification and update of test standards, the reduction of test costs, and the privacy protection of test data. Addressing these challenges requires the joint efforts of the entire industry, including strengthening international cooperation, promoting technological innovation, and improving laws and regulations.

6. Conclusion

In summary, the importance of lithium battery testing machine as a key equipment for lithium battery research and development, production and quality control is self-evident. It not only helps developers quickly select the optimal material formulation and optimize the battery design, but also enables effective quality control during the production process to ensure that every battery meets design requirements and safety standards.

As a manufacturer of lithium battery materials and equipment, we understand the importance of lithium battery testing machines to improve battery performance and safety. Therefore, we will continue to increase research and development investment, constantly optimize product performance, provide customers with more advanced and reliable lithium battery test solutions, and jointly promote the prosperity of the new energy industry. At the same time, we also look forward to working with colleagues in the industry to jointly address challenges, seize opportunities, and create a better future for lithium battery testing technology.