The complete set of equipment for coin cell (or button cell) laboratory research

The complete set of equipment for coin cell (or button cell) laboratory research is crucial in the field of battery research and development. It encompasses a range of devices for both the fabrication and performance testing of coin cells.

1. Fabrication Equipment for Coin Cells

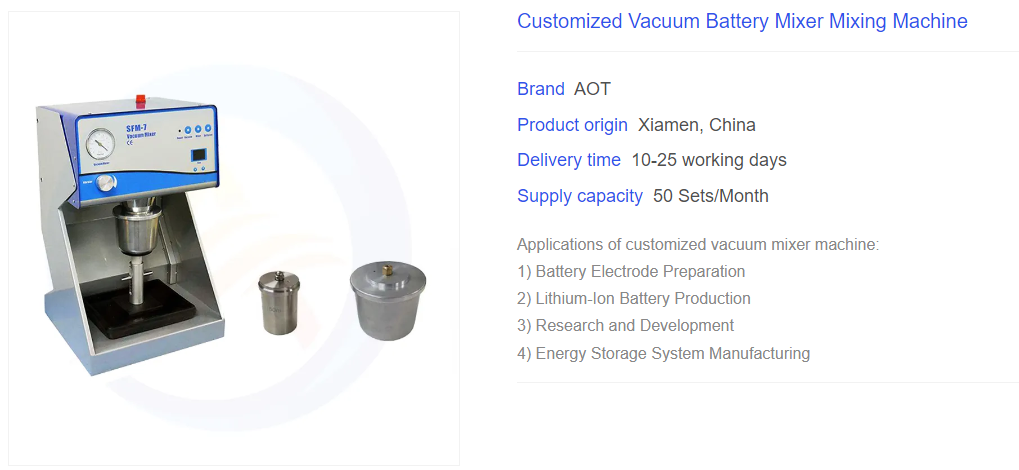

1) Mixer: Utilized for blending battery materials to ensure homogeneity, serving as the foundational equipment in battery manufacturing.

Function: Used to mix battery materials to ensure a uniform distribution.

Features: Adjustable mixing speed and time to accommodate different material mixing requirements.

2) Coating Machine: Designed to apply the mixed materials onto electrode sheets, forming a uniform electrode layer.

Function: Applies electrode material onto a substrate to form a uniform electrode layer.

Features: Heating function aids in better adhesion of materials to the substrate, enhancing electrode quality.

3)Electric Rolling Mill: Used to roll electrode sheets, enhancing their density and uniformity.

Function: Rolls battery materials such as electrode sheets to achieve desired thickness and density.

Features: Electric drive for easy operation, adjustable rolling thickness suitable for various material rolling needs.

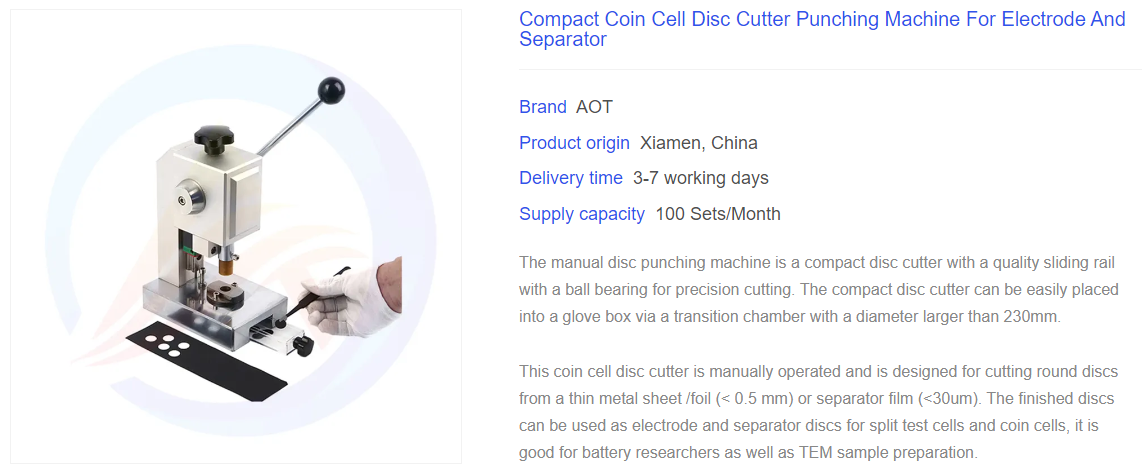

4)Manual Coin Cell Cutting Machine: Employed to cut electrode sheets to meet the size requirements of coin cells.

Function: Cuts electrode sheets and other materials for button cells to ensure accurate dimensions.

Features: Manual operation for flexibility, suitable for small-batch production and laboratory research.

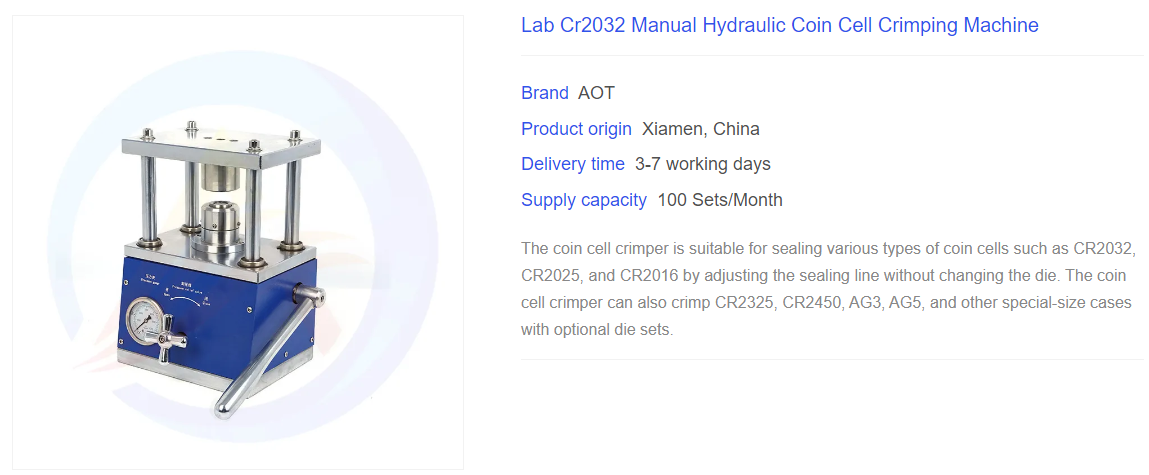

5)Pressure-Controlled Electric Coin Cell Sealing Machine: For encapsulating coin cells, ensuring their sealability and stability.

Function: Seals button cells to ensure good sealing performance and prevent electrolyte leakage.

Features: Pressure-controllable for stable sealing quality, suitable for sealing different specifications of button cells.

2. Performance Testing Equipment for Coin Cells

1) Battery Internal Resistance Tester: Measures the internal resistance of coin cells to assess their conductivity and internal resistance changes.

2) Electrochemical Workstation: A vital device for studying electrochemical reactions, capable of measuring coin cells' charge-discharge curves, charging and discharging performance, and more. It serves as the core equipment for coin cell performance research.

3) Constant Voltage and Constant Current Charge-Discharge Testing System: Through constant current and voltage charging and discharging, it measures parameters such as coin cells' charge-discharge curves, capacity, and internal resistance, providing comprehensive testing and evaluation of battery performance.

4) Temperature and Humidity Chamber: Simulates the operating environment of coin cells under different temperatures and humidity levels, facilitating accelerated life testing and performance evaluation.

Scanning Electron Microscope (SEM): Observes the microstructure and morphology of coin cells, such as electrode material particle size, distribution, and internal defects within the battery.

3. Additional Auxiliary Equipment

1) Vacuum Drying Oven: Used for drying coin cells or their components to remove moisture and other volatile substances.

2) Glove Box with Dehydration and Deoxygenation: Provides a high-cleanliness, high-purity gas environment for the fabrication and testing of coin cells, preventing reactions between air and battery materials.

3) Analytical Balance: Precisely measures the mass of battery materials to ensure accurate ratios.

4) Viscometer: Measures the viscosity of battery materials to evaluate their fluidity and processability.

In summary, the complete set of equipment for coin cell laboratory research covers multiple aspects, including battery fabrication, performance testing, and auxiliary equipment, providing comprehensive support for coin cell research and development. The application of these equipment not only improves battery performance and stability but also drives continuous innovation and development in battery technology.