In today's rapidly developing new energy industry, lithium batteries, as the core energy storage technology, are widely used in electric vehicles, portable electronic equipment, energy storage systems and other fields. The research and development and production of lithium batteries not only require high-precision process control, but also need to be carried out under strict environmental conditions to ensure the performance, safety and service life of the battery. Among them, the lithium battery glove box, as a key equipment, plays an indispensable role in the preparation of lithium battery materials, battery assembly and testing.

1.the basic overview of lithium battery glove box

1.1 Definitions and Functions

Lithium battery glove box is a highly sealed, anaerobic and water-free working environment system designed for the development and production of lithium batteries. By creating a low oxygen, low water and even anaerobic anhydrous environment in the box, it effectively prevents the negative impact of oxygen, water and other impurities in the air on lithium battery materials, electrolytes and batteries, and ensures the purity and stability of lithium batteries in the preparation process.

1.2 Structure and composition

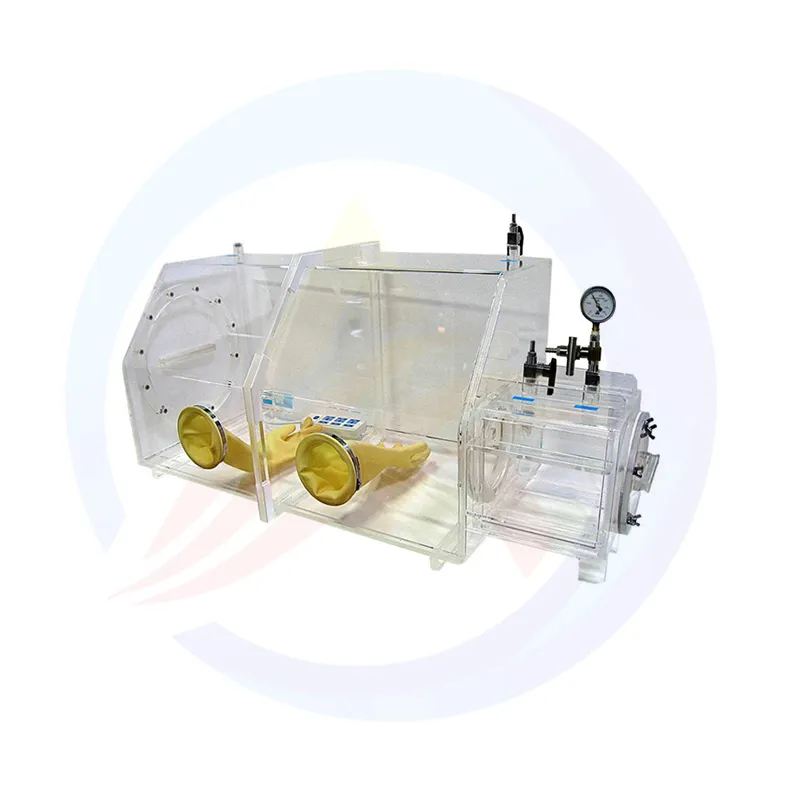

Lithium battery glove box is usually composed of box, glove mouth, gas purification system, pressure control system, monitoring system and safety device. The box is made of high-strength, corrosion-resistant material, and the internal space can be flexibly adjusted according to demand; The glove mouth allows the operator to operate inside the box while keeping the environment sealed; The gas purification system continues to remove trace oxygen and water in the box through circulation filtration; The pressure control system maintains the small positive pressure inside the box to prevent the intrusion of external pollutants; The monitoring system monitors the environmental parameters in the box in real time to ensure that the working environment meets the requirements; Safety devices include emergency stop button, leakage alarm, etc., to ensure safe operation.

2.the core role of lithium battery glove box

2.1 Protect materials from contamination

In the synthesis, storage and assembly of lithium battery materials, very small oxygen and moisture content can significantly affect the electrochemical performance, cycle stability and safety of the battery. The lithium battery glove box effectively avoids these harmful factors by providing an almost oxygen-free and water-free environment, ensuring the high purity of the material and the consistency of the battery's performance.

2.2 Improve R&D efficiency

In the laboratory environment, researchers can directly carry out experimental operations such as material synthesis, modification, electrode coating, and battery assembly in the glove box, without frequent transfer of samples to different environments, greatly shortening the research and development cycle and improving work efficiency.

2.3 Ensure production quality

In large-scale production, the application of lithium battery glove box ensures that each process is carried out under strictly controlled environmental conditions, reduces batch differences caused by environmental factors, improves the overall quality and consistency of battery products, and helps enterprises to establish a stable supply chain and brand image.

2.4 Security Protection

The materials involved in the development and production of lithium batteries are mostly flammable and explosive or corrosive, and the glove box not only isolates these harmful substances from direct contact with the operator, but also prevents accidental leakage and explosion accidents through its safety design, providing a safe working environment for the staff.

3.lithium battery glove box application field

3.1 Laboratory Research and Development

In the research and development stage of new materials and new processes for lithium batteries, the glove box is an indispensable scientific research tool. It supports the whole process from basic material research to battery prototype design, helping researchers to deeply explore the relationship between material structure and performance, and accelerate the transformation of new results.

3.2 Small batch trial production

In the new product development stage, small batch trial production requires precise control of the production environment. Lithium battery glove box provides the ideal test platform, so that enterprises can fully verify the production process and product quality before the formal production, reduce the risk.

3.3 Production Line Application

With the advancement of technology, some high-end lithium battery production lines have also begun to introduce glove box systems, especially in key processes such as electrode preparation, electrolyte injection, and battery packaging, to further improve product quality and production efficiency.

3.4 Material analysis and testing

In the field of materials science, the glove box is also used for physical performance testing, electrochemical performance testing and failure analysis of lithium battery materials to ensure the accuracy and reliability of test results.

4.how to choose the appropriate lithium battery glove box

4.1 Dimensions and capacity

Select the appropriate box size and capacity according to the actual requirements. Small glove box suitable for laboratory research and development, easy to move and rapid deployment; Large glove boxes are more suitable for production line applications and can meet the needs of high-volume operations.

4.2 Purification efficiency and maintenance capacity

Examine the efficiency and stability of the gas purification system of the glove box, especially its ability to remove oxygen and moisture, and its performance retention after long periods of operation. An efficient gas purification system is the key to the environment in the cage.

4.3 Operation convenience and safety

The operation interface of the glove box should be intuitive and easy to use. The glove material should be wear-resistant, comfortable, and well sealed. At the same time, attention should be paid to its safety design, such as emergency stop button, gas leak alarm, overvoltage protection, etc., to ensure safe operation.

4.4 After-sales service and technical support

Choose brands with good after-sales service and technical support to ensure that problems encountered in the use process can be solved in time to ensure the smooth progress of production or research and development.

5. Conclusion

In the future, with the continuous emergence of new materials and new processes, the design and function of the lithium battery glove box will continue to be optimized and upgraded to better serve the innovative development of the lithium battery industry. As a manufacturer of lithium battery materials and equipment, we keep up with industry trends, continue to innovate, provide customers with more efficient, safe and intelligent lithium battery glove box solutions, and jointly promote the prosperity and development of the new energy industry.