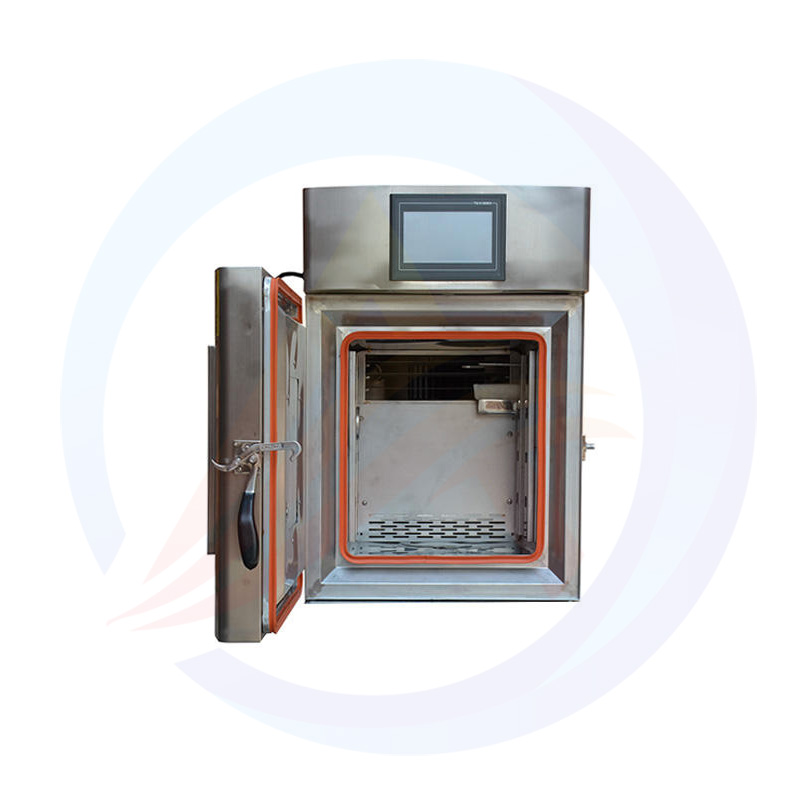

| High-Low Temperature Chamber AOT-HLC-42L |

| AC 220V±10%, 50HZ (custom voltage available) |

| 3500W |

| One year limited warranty with life time technical support |

| -20℃ to 150℃ |

| Less than ±0.5℃ |

| Less than ±1℃ |

| Less than ±2℃ |

Temperature rise and fall

| From 20℃ to -20℃, about 40 minutes |

From 20℃ to 100℃, about 40 minutes |

| 20% - 98%R.H (AT+25℃~+85℃) |

| +2/-3%R.H (above 75%R.H ) , ±5% R.H (under 75%R.H ) |

| 1.7m/s to 2.5m/s |

The data above is measured under ≤25℃, normal pressure, no-load and no-load conditions, 1/6 space from the inner wall of the cabinet. |

| 350*300*400mm |

| 550*870*1400mm |

| One 50mm diameter hole on the side on chamber(can be customized) |

| SUS304 mirror stainless steel plate |

| SUS304 stainless steel |

| A multi-layer insulating glass observation window is installed on the gate, and a heating anti-frost device is provided. |

| A (AC12V) 20W halogen lamp is installed on the chamber door. |

| With over temperature protection, grounding etc |

| Two-layer adjustable height stainless steel strip shelves |