4. It is forbidden to put the material directly on the bottom brick, please put the material in a special crucible.

5. When heating, the material and crucible should not touch the heating element and thermocouple.

6. When not in use for a long time, please use the oven again.

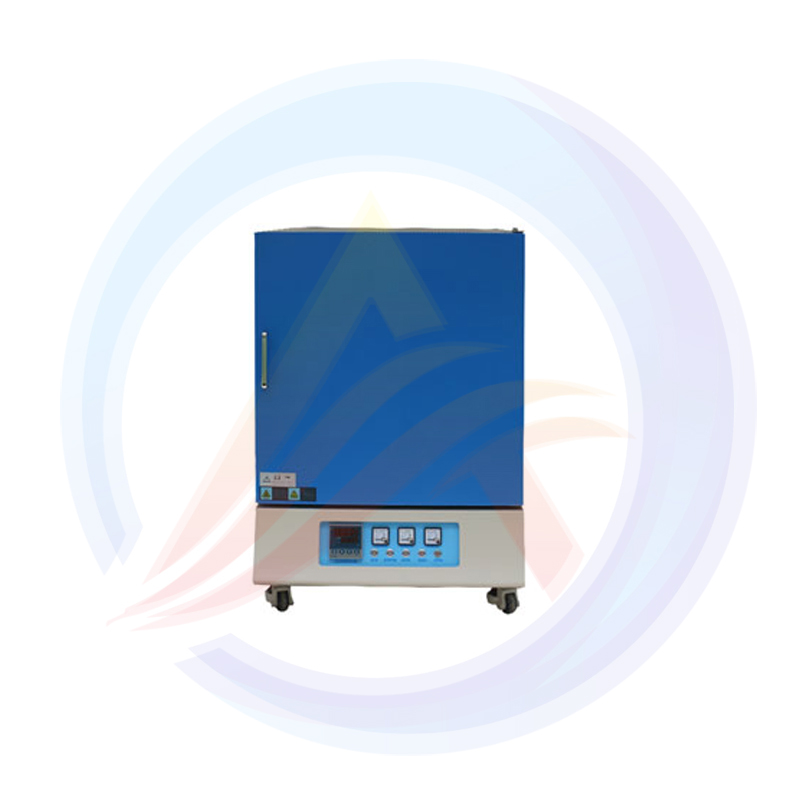

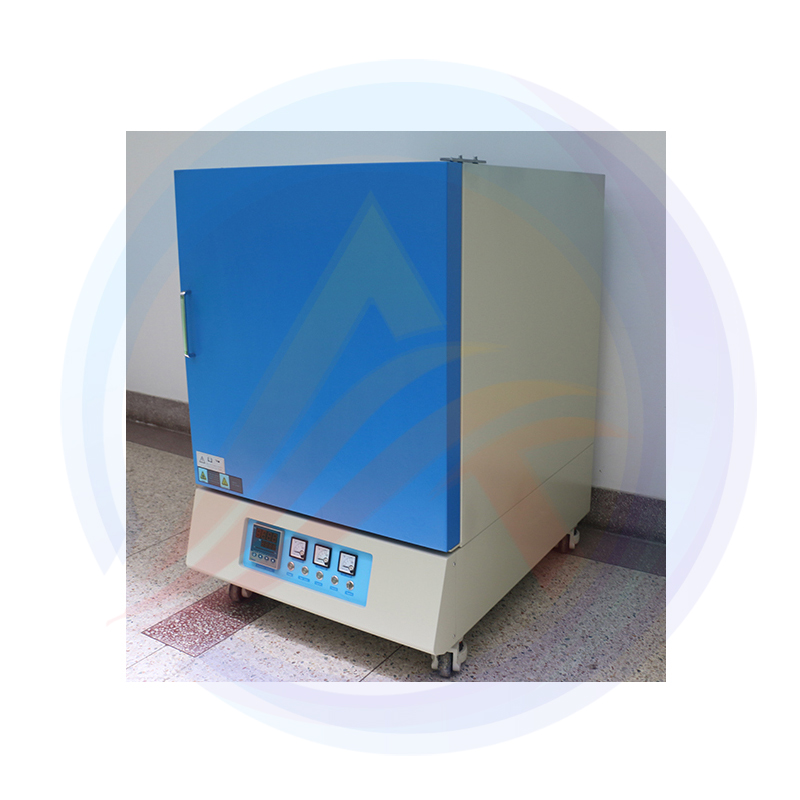

box Furnace AOT-KBF1700:

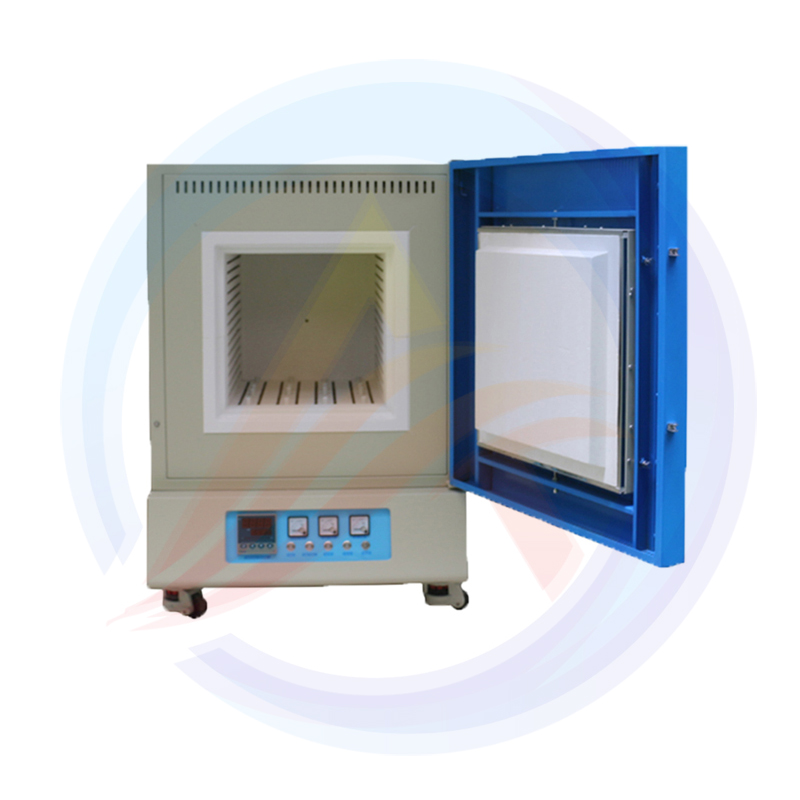

The furnace is made of alumina polycrystalline fiber material with high quality, It is energy-saving.

/Box Furnace AOT-KBF1700:

Intelligent PID programmable temperature control offers advantages like a balanced temperature field, low surface temperature, and fast temperature rise and fall rate.

The outer Structure of the box furnace

External material selection is guaranteed, sturdy, and durable, with a stable structure.

The internal materials of the box furnace

Stable internal materials and easy to operate are widely used in university laboratories, scientific research institutes, and corporate factories

Q1: How does a box furnace work?

A box furnace works by utilizing heating elements, usually made of materials like silicon molybdenum rods, to generate heat. The box furnace consists of a cylindrical chamber or tube where the sample or material to be heated is placed. The heating elements, often located on the outside of the tube, heat up the chamber uniformly.

Q2: What is the heating temperature in the tube furnace of the thermal cracking process?

In the thermal cracking process, the heating temperature in a tube furnace typically varies depending on the specific requirements of the process. It can range from several hundred degrees Celsius to over a thousand degrees Celsius. The exact temperature is determined by factors such as the desired reaction kinetics, the type of feedstock being cracked, and the desired product yield. The heating temperature is carefully controlled and maintained within the furnace to ensure efficient and controlled cracking of the feedstock.

Q3: How to use a battery box furnace?

To use a battery box furnace:

1. Preparation: Ensure the battery box furnace is properly connected to a power source and any necessary gas or vacuum supply.

2. Loading: Open the furnace and carefully place the sample or material to be heated inside the tube or chamber.

3. Setting parameters: Set the desired temperature of the furnace using the temperature control panel or interface. Adjust any additional parameters such as heating rate, holding time, or gas flow rate if applicable.

4. Starting the heating process: Close the furnace and initiate the heating cycle by activating the power supply. The heating elements inside the furnace will gradually increase the temperature to reach the desired level.

5. Monitoring: Continuously monitor the temperature using the built-in temperature control instrument or an external thermometer.

6. Cooling: Once the desired heating process is complete, gradually decrease the temperature or turn off the power supply to initiate the cooling process.

7. Unloading: After the furnace has cooled down to a safe temperature, open it and carefully remove the sample or material.

8. Maintenance: Clean the furnace chamber and ensure it is in proper condition for future use.

Q4: How can a battery box furnace be applied to battery production?

Electrode Materials Preparation: Furnaces are used to heat treat and activate electrode materials such as cathodes and anodes. The materials are coated onto current collectors and then heated in the furnace to optimize their structure and properties for improved battery performance.

Sintering: Furnaces are used for sintering processes, where the active materials in the electrodes are fused together to create a cohesive structure. This enhances the conductivity and stability of the electrodes. etc.