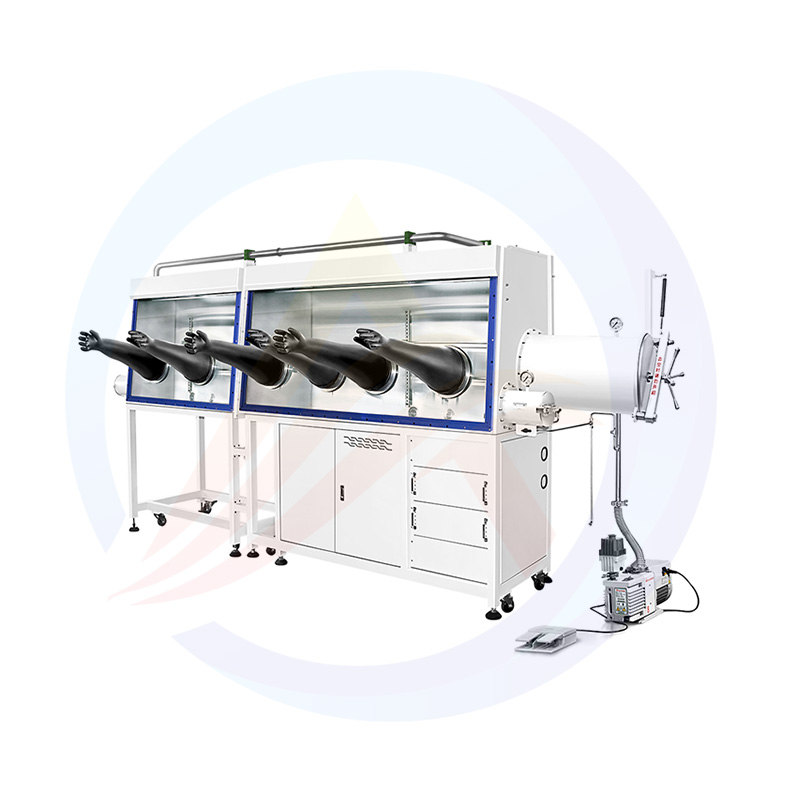

| high vacuum glove box |

| Box | Material: 304 stainless steel, thickness 3mm |

| Outer surface: 304 stainless steel |

| Inner surface: oil film drawing surface |

| Size: optional length 1500, 1800, 2440, 3660, 4880, 7320mm |

| Optional depth of 750, 1000, 1200mm |

| Height 900mm |

| Front window | Tilting window: transparent toughened safety glass, thickness 8mm |

| Glove mouth | Material is POM or aluminum alloy: O-ring seal |

| gloves | Butyl rubber: thickness 0.4mm, diameter 7'' or 8'' |

| filter | Specification: 0.3μm, one gas inlet, and one gas outlet |

| Shelf | Material: stainless steel, built-in 2 layers, height adjustable |

| Cabinet Lighting | Location: LED light, installed in the lampshade |

| interface | Specification: DN40KF, several spare interfaces, 1 power interface (220V) |