-

Home

-

Products

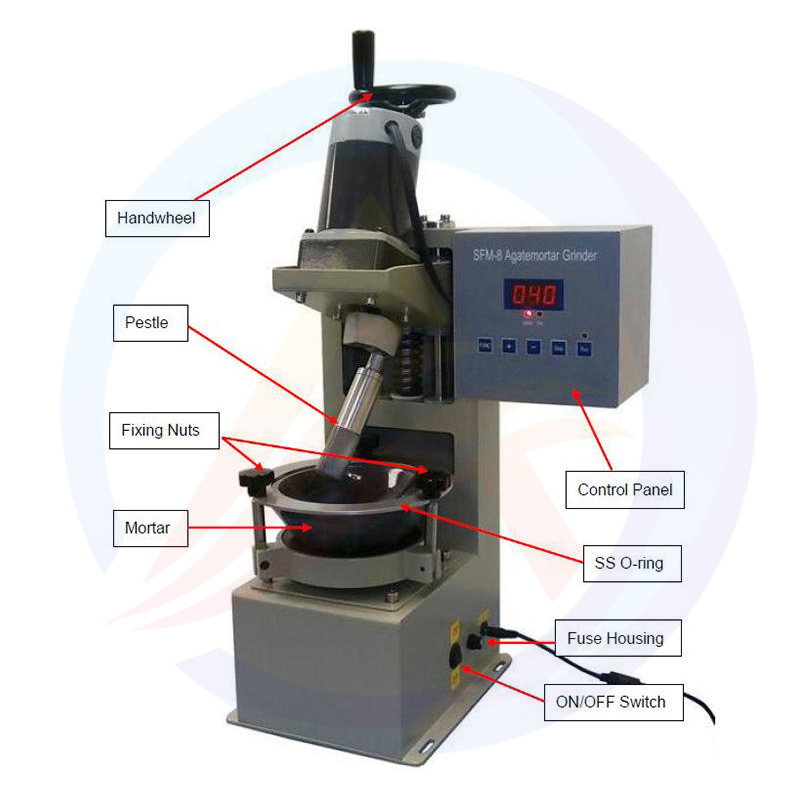

- Ball Mill

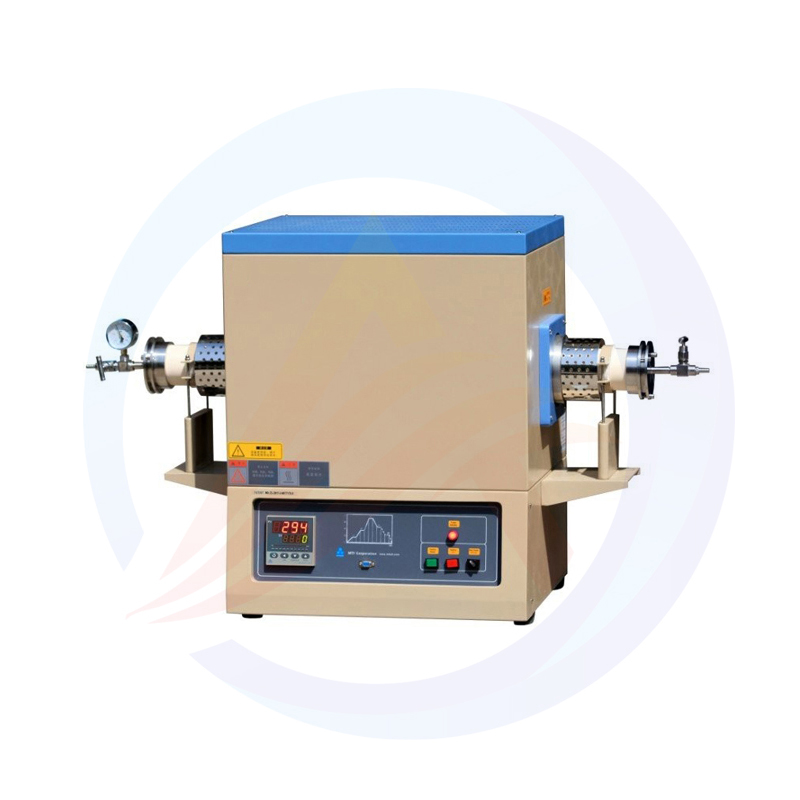

- Lab Furnace

- Battery Mixer Machine

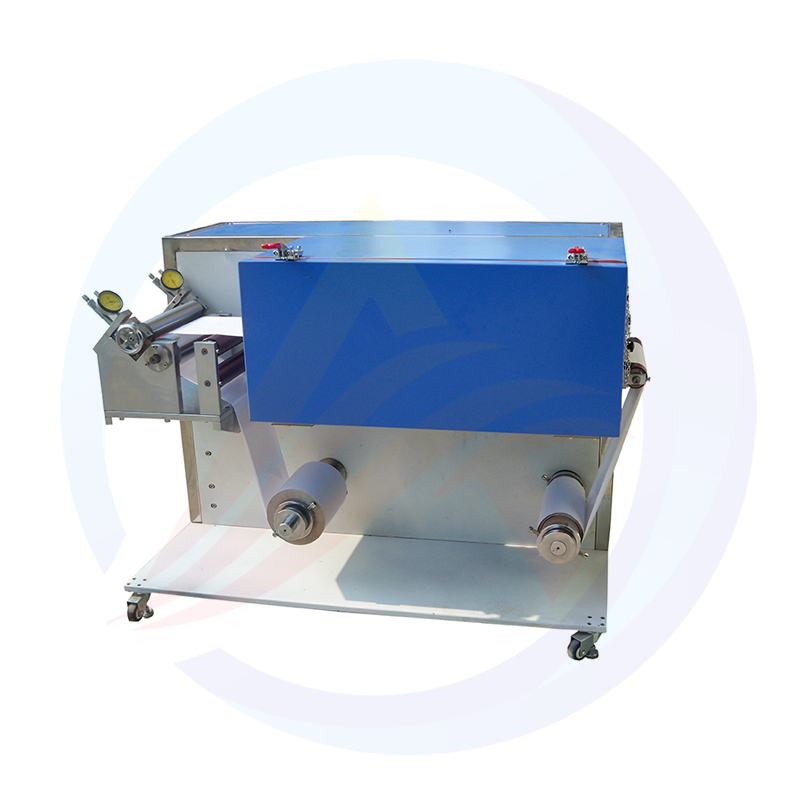

- Battery Coating Machine

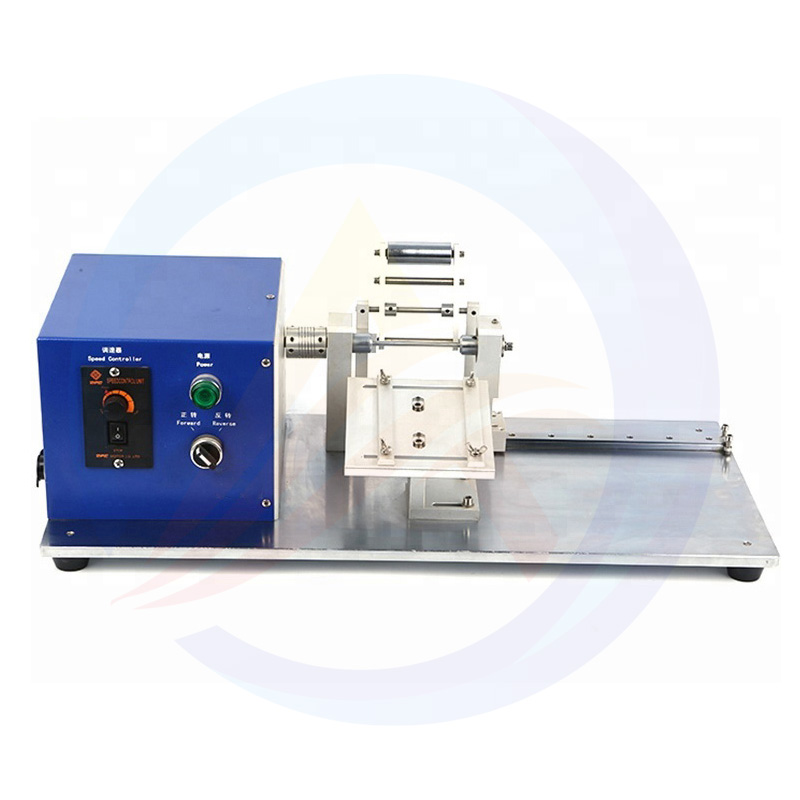

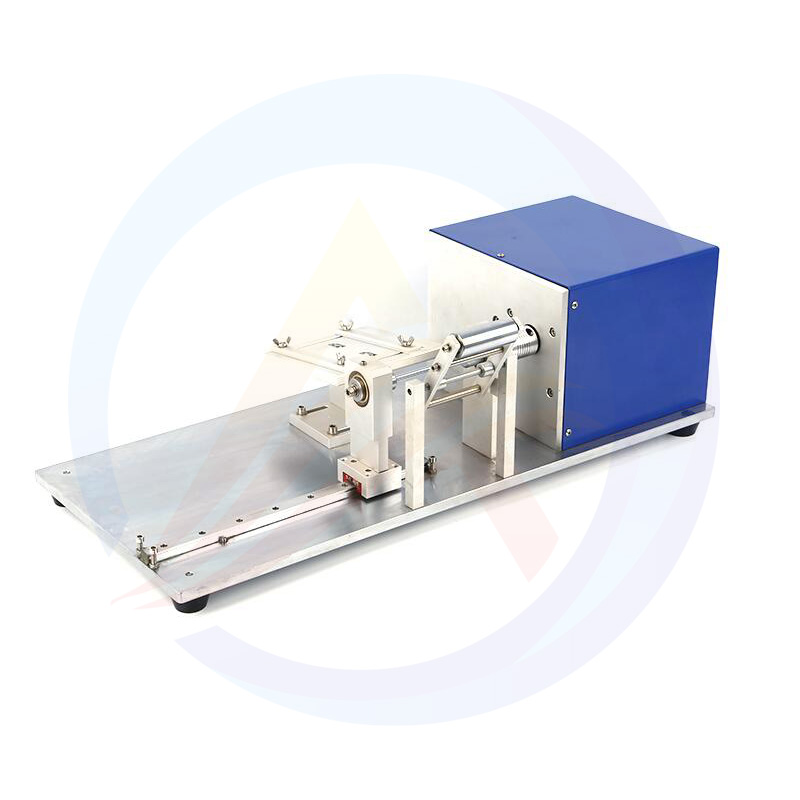

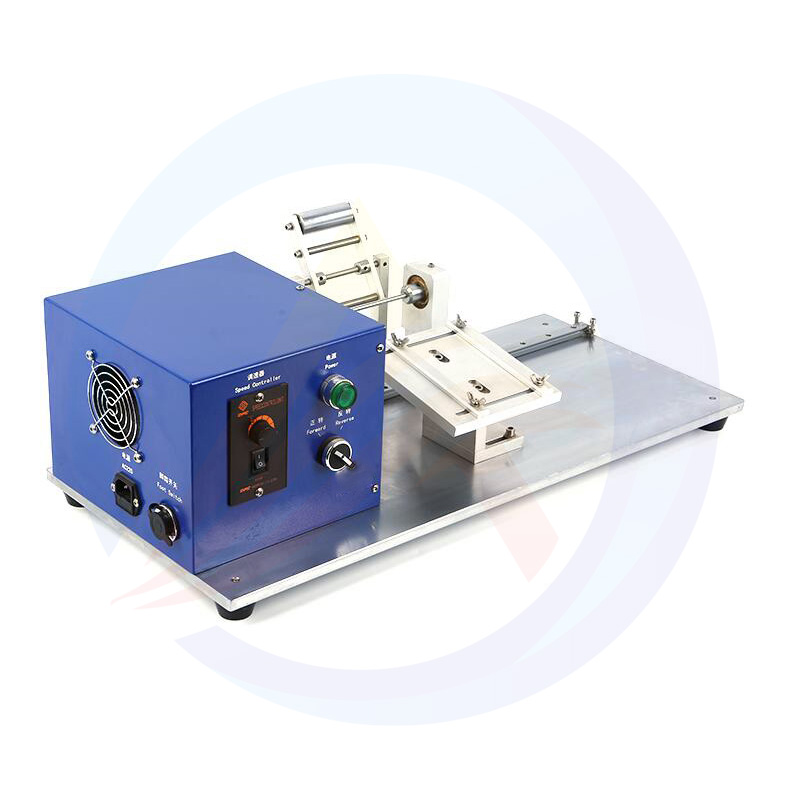

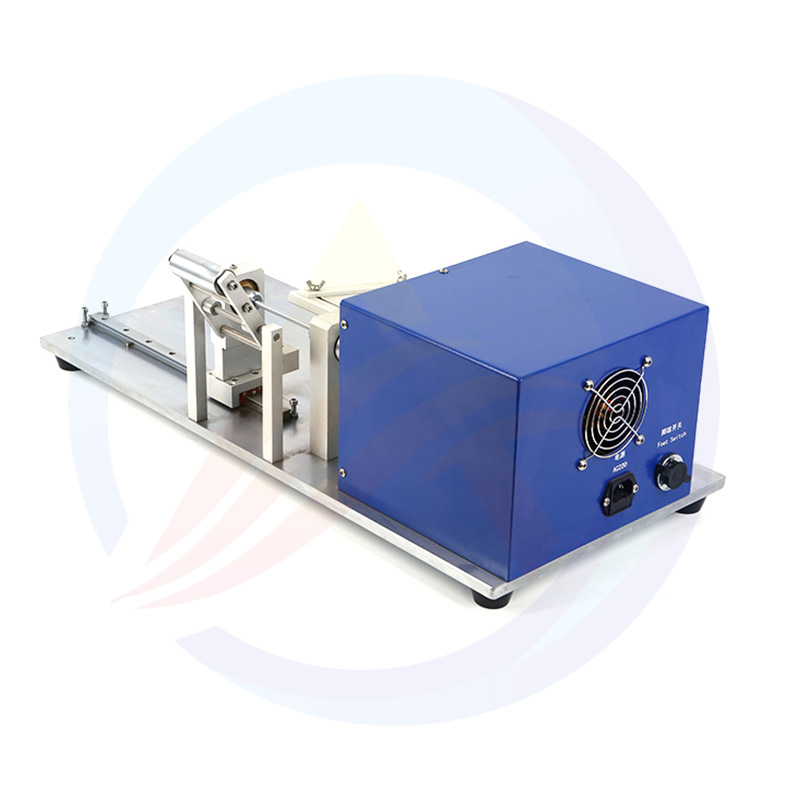

- Roller Press

- Electrode Slitting Machine

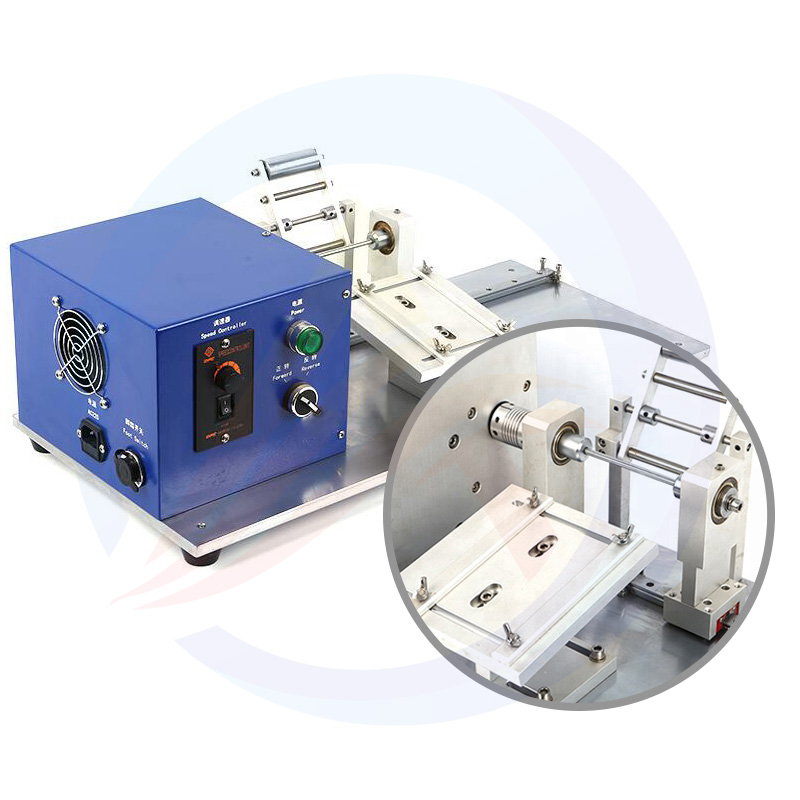

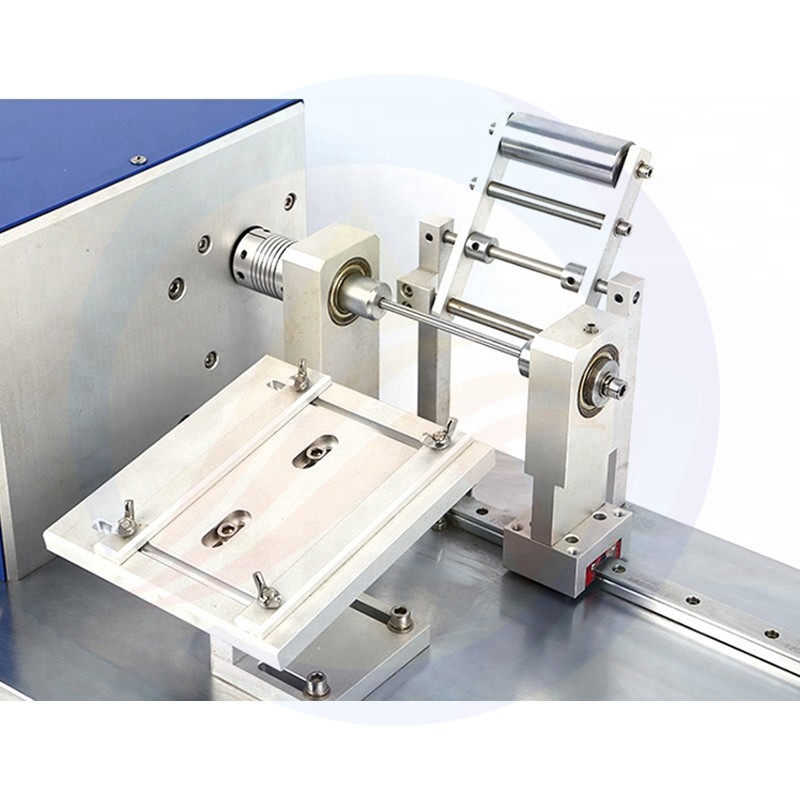

- Electrode Die Cutting Machine

- Battery Stacking Machine

- Battery Winding Machine

- Battery Sealing Machine

- Battery Spot Welding Machine

- Vacuum Glove Box

- Battery Tester

- Cylindrical Battery Pack Assembly Machine

-

Drying Oven

-

News

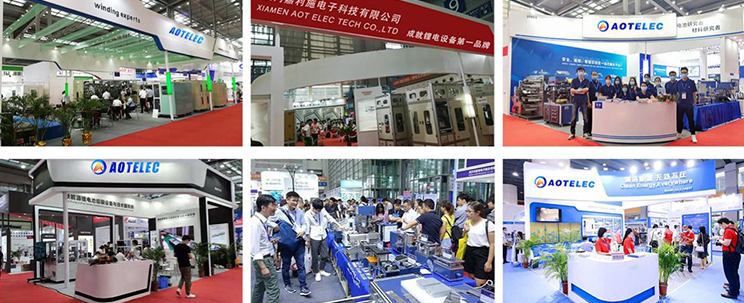

- Case

- Factory Show

-

Contact Us

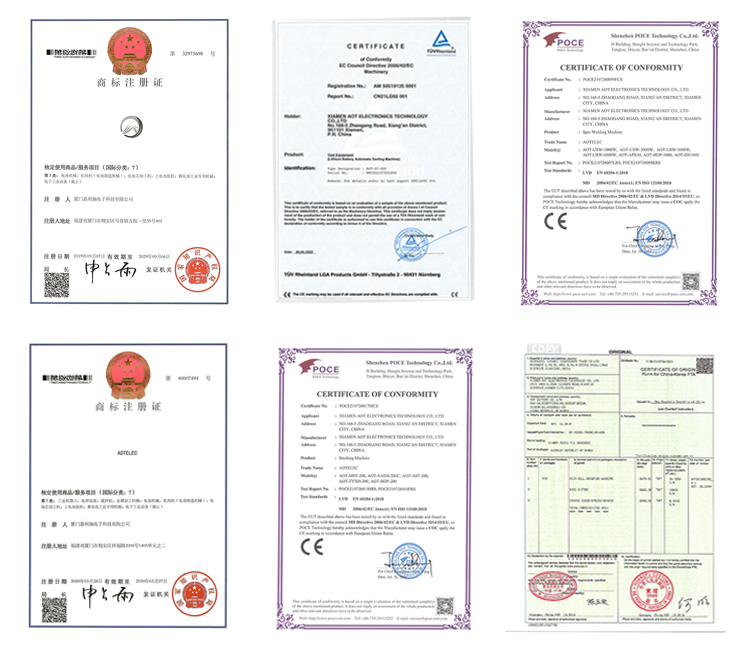

- About Us

-

Videos