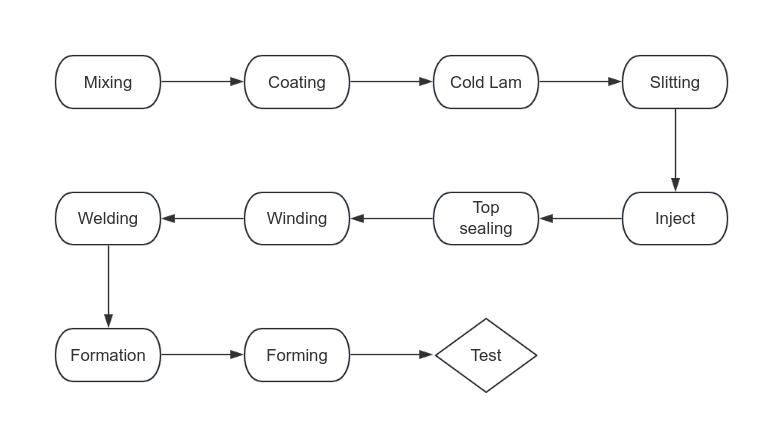

Lithium battery manufacturing winding process

In the manufacturing process of lithium batteries, the winding process plays a crucial role in improving the energy density, cycle life, and safety of lithium batteries.

Introduction to winding process

The winding process is the core link in the manufacturing process of lithium batteries, mainly involving the process of winding positive electrode, negative electrode, separator and other materials into battery cells in a certain order and direction under certain tension control. The quality of the winding process directly affects the performance and lifespan of lithium batteries, therefore, in-depth research and optimization of the winding process is of great significance.

Winding process flow

Material preparation: Before the winding process begins, it is necessary to prepare the positive electrode, negative electrode, diaphragm and other raw materials according to certain specifications and quantities. These materials need to be tested to ensure that their performance and quality meet the process requirements.

Tension control: During the winding process, a certain amount of tension needs to be applied to the material to ensure the flatness and tightness of the winding. The magnitude of tension needs to be precisely controlled based on material characteristics and process requirements.

Winding forming: After preparing the raw materials and applying appropriate tension, the winding machine will roll according to the preset trajectory and speed. During the winding process, it is necessary to maintain a stable winding speed and tension to ensure that the structure and size of the battery cell meet the design requirements.

Quality inspection: After the winding is completed, a comprehensive quality inspection of the battery cells is required. The testing content includes the appearance, size, weight, and performance parameters of the battery cells. Only qualified battery cells can enter the next process.

Subsequent processing: For qualified battery cells, further packaging and assembly are required to ultimately form usable lithium battery products.

Key technologies and difficulties

Tension control technology: Tension control is one of the core technologies in the winding process. The stability of material tension during the winding process has a significant impact on the flatness and tightness of the winding. In order to achieve precise tension control, advanced sensors and control systems are needed to monitor the tension status of materials in real time and make adjustments. In addition, research and optimization of tension control algorithms are needed for different materials and process requirements.

Winding speed and stability: The winding speed determines production efficiency, while stability directly affects the quality of battery cells. Improving the winding speed while ensuring stability is another key technology in the winding process. To achieve this goal, it is necessary to study the dynamic characteristics during the winding process, optimize the structure and motion control algorithm of the winding machine, in order to improve its dynamic response ability and stability.

Automatic correction and alignment: During the winding process, the material is prone to deviation and deviation, which may lead to structural and dimensional deviations of the battery cells. Therefore, the development and application of automatic correction and alignment technology are of great significance for improving the consistency and qualification rate of battery cells. This technology involves multiple fields such as optoelectronic detection, image processing, and motion control, and requires comprehensive application of relevant theories and technologies for in-depth research.

Adaptability issues of new materials: With the development of technology, new electrode materials (such as silicon-based negative electrode materials) and diaphragm materials continue to emerge. These materials have significant differences in physical properties from traditional materials, posing new challenges to the winding process. How to adapt to the characteristics of new materials and optimize the winding process parameters is one of the urgent problems to be solved.

Environmental protection and safety: In the manufacturing process of lithium batteries, various organic solvents and other harmful substances are involved. Therefore, it is worth paying attention to how to reduce environmental pollution and production safety risks while ensuring the quality and efficiency of the winding process. In the future, it is necessary to research green manufacturing technologies and environmentally friendly solvent alternatives to achieve sustainable development in lithium battery manufacturing.

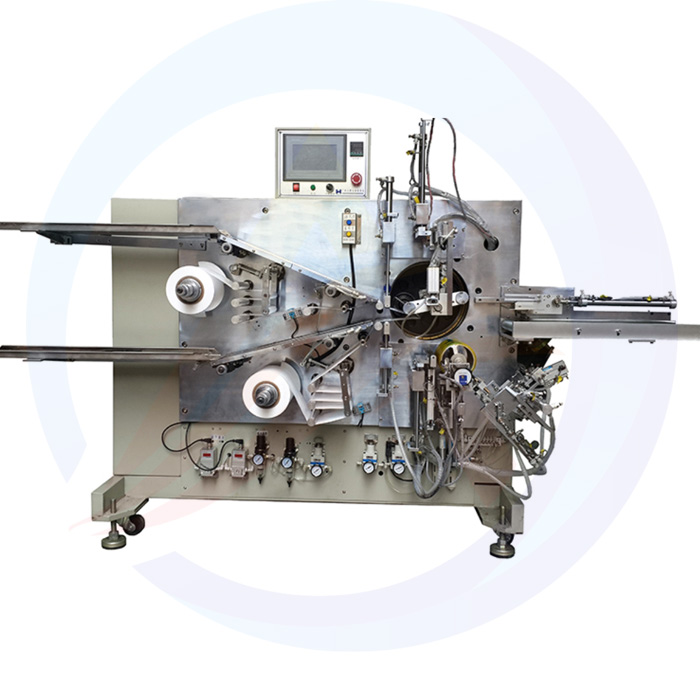

Automation Winding Machine

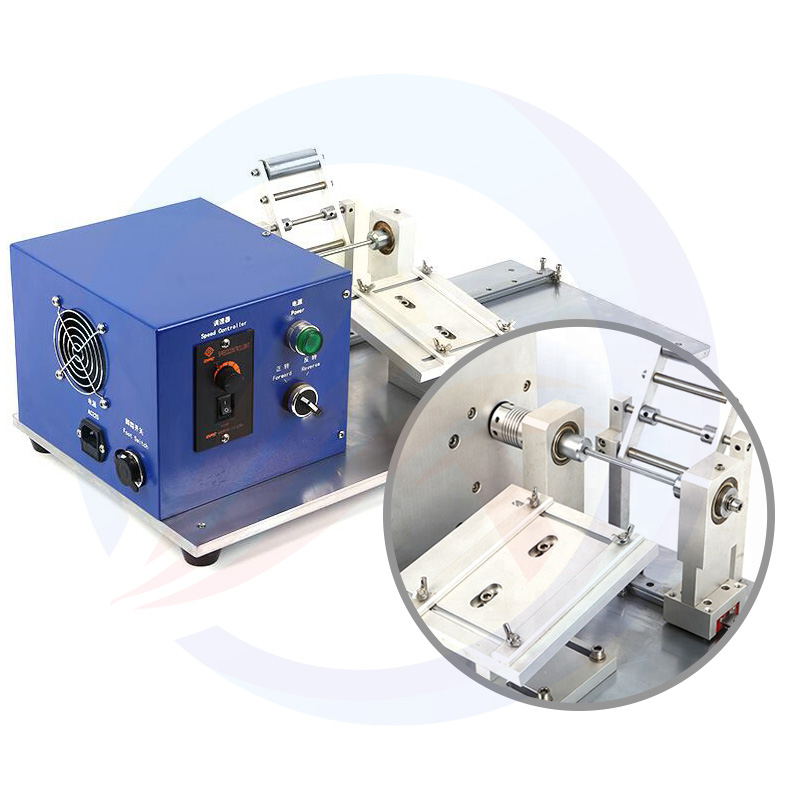

Semi-automatic Wnding Winder