China lithium coater industry

Lithium coater industry definition

Lithium coating machine is a professional for lithium ion battery electrode manufacturing core equipment, its main function is in the process of continuous operation, the paste containing active substances (such as anode electrode material, cathode electrode material), conductive agent, binder, etc., is accurately and evenly coated on the battery electrode substrate (usually copper foil or aluminum foil). A pole film coating with a certain thickness and mass distribution is formed. The quality of the coating process directly affects the core performance indicators of the final lithium-ion battery, such as energy density, charge-discharge performance, cycle life and safety.

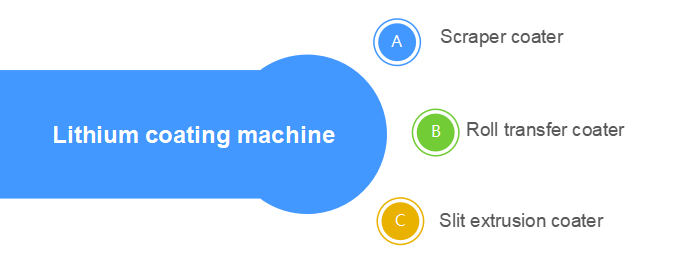

Lithium coater industry classification

The classification of lithium coater is mainly based on its unique coating method, which covers many types such as scraper type, roll coating transfer type and slit extrusion type. The scraper coater is widely used in laboratory equipment for its simple operation and low cost. It uses the scraper to evenly coat the battery paste on the substrate. However, its applicability is limited for large-scale production or coating scenarios requiring high accuracy. The roll transfer coater is suitable for the production of 3C batteries, which relies on one or more rolls to accurately transfer the paste to the substrate, achieving fast coating while ensuring a good surface quality. However, this approach may present some challenges in terms of coating thickness and uniformity. The slit extrusion coater occupies an important position in the production of power batteries with its high precision and uniformity. It extrudes the slurry directly to the substrate through a precise slit, which not only meets the needs of large-scale production, but also effectively handles high-viscosity slurry, showing its unique advantages.

Lithium coating machine industry on the middle and downstream

On the upstream side, it relies on metal material suppliers to provide high-quality alloys or stainless steel for manufacturing parts such as rolls and scrapers, requires the precision machining and manufacturing industry to participate in the production of its core mechanical parts, and electrical control system manufacturers to provide sensors and control technology to ensure the accurate operation of equipment. Software developers and algorithm experts assist in integrating advanced software systems to optimize the coating process. In the downstream application industry, lithium coater mainly serves the lithium battery manufacturing industry, and lithium batteries are widely used in electric vehicles, mobile electronic devices, energy storage systems and aerospace and military and other fields, these application areas have strict requirements for battery performance, thus promoting the development and improvement of coating technology.

China's lithium coater industry market size and growth rate

As a crucial part of the lithium battery equipment system, the market size of the lithium battery equipment accounts for 15%-18% of the overall scale, playing the role of core production equipment. In recent years, with the rapid expansion of the lithium battery industry, the growth momentum of the lithium coater market is particularly strong. According to the statistics in 2021, the total value of the global lithium coating equipment market has reached 12.7 billion yuan, with an annual growth rate of 59%; Among them, the share of the Chinese market is quite significant, reaching 72.4%, the corresponding market size of 9.2 billion yuan, the growth rate is more than double. Forecasts show that by 2025, China's lithium coating equipment market size will be further expanded, is expected to climb to a new height of 41.1 billion yuan.

In recent years, under the unremitting efforts of domestic enterprises and continuous technological innovation, the localization process of China's coating machine has achieved remarkable results. As of 2021, the overall localization rate of China's lithium-ion battery production equipment has exceeded 85%, especially in the field of coating equipment, the localization rate is more than 98%. This achievement highlights China's major breakthrough in the autonomy of lithium coating technology. At the same time, the coating equipment independently developed and produced in China has been significantly improved in a number of key technical indicators, such as coating speed, coating width, batch coating thickness control and coating accuracy, and has gradually narrowed the gap with similar products in Japan and South Korea, and has surpassed in some key technical parameters. It shows the increasingly strong competitiveness and technical strength of China's lithium coating equipment industry. This means that China's coating equipment has not only achieved a substantial increase in market share, but also reached the international leading ranks in terms of technology level.

Lithium coater industry development prospects forecast

The development prospects of the lithium coating machine industry are particularly bright in the context of today's new energy era, it is not only a key link in the lithium-ion battery manufacturing industry chain, but also closely follow the pace of global green energy transformation, with broad room for growth and sustained market demand. With the explosive growth of the electric vehicle industry, the surge in demand for renewable energy storage and the demand for higher energy density batteries in the consumer electronics field, the market potential of the lithium coater industry will continue to be released. Technological progress and changes in market demand promote the development of lithium coating machines in the direction of diversification, intelligence and green. On the one hand, in order to meet the needs of new battery materials and battery design, such as solid state batteries, high-nickel ternary material batteries, etc., coater needs to have the ability to handle a variety of different characteristics of the slurry and higher coating accuracy. On the other hand, the construction of intelligent production line requires higher integration of coating machine, with automation, information and Internet of Things technology, to achieve real-time monitoring and intelligent regulation of the whole process.

The trend of localization replacement is obvious, and the advantages of domestic lithium coater in cost-effective, after-sales service and response speed are becoming more prominent, and the market share is gradually increasing, which effectively promotes the autonomous controllability and supply chain security of the industry. However, it also means that domestic enterprises have to make continuous progress in technology research and development, process optimization and quality control to cope with the increasingly fierce domestic and foreign market competition. In summary, the development prospects of the lithium coating machine industry are optimistic, and it is expected to maintain a stable and rapid growth trend in the next few years. With the adjustment of the global energy structure and the continuous breakthrough of battery technology, the lithium coating machine industry will play an increasingly important role in the tide of global energy change, and will continue to derive new market opportunities and business forms. At the same time, the industry will also face constant technology iteration, quality upgrading and international competition and other challenges, the need for continuous innovation and optimization, in order to adapt to the changing market demand and environmental requirements.