Lithium coater development: single-side coating→ double-side coating

Coating process is a process based on the study of fluid properties, which involves coating one or more layers of liquid onto a substrate. The substrate is usually a flexible film or backing paper, and then the coated liquid coating is dried in an oven or cured to form a special functional film layer.

Lithium-ion power battery electrode coating process has its own characteristics:

1) Double-sided single-layer coating in turn, most of the double-sided coating machines on the market are also double-sided coating in turn

2) The slurry wet coating is thicker, generally 100 ~ 300μm

3) The slurry is a non-Newtonian high-viscosity fluid

4) Relative to the general coating products, the electrode coating accuracy requirements are high

5) The coating base material is aluminum foil or copper foil with a thickness of 4~30 μm

At present, the lithium-ion power battery industry has widely used slit extrusion coating technology to manufacture battery electrode sheets. Extrusion coating technology can obtain high precision coating, but also can be used for higher viscosity fluid coating. In the actual process, the uniformity, stability, edge and surface effects of the coating solution are affected by the rheological properties of the coating solution, which directly determines the quality of the coating. Many researchers are committed to the study of coating window by means of theoretical analysis, coating experiment technology, fluid mechanics finite element technology and other research methods. Coating window is the process operation range in which stable coating can be applied and uniform coating can be obtained, which is affected by three types of factors:

1)fluid characteristics, such as viscosity μ, surface tension σ, density ρ;

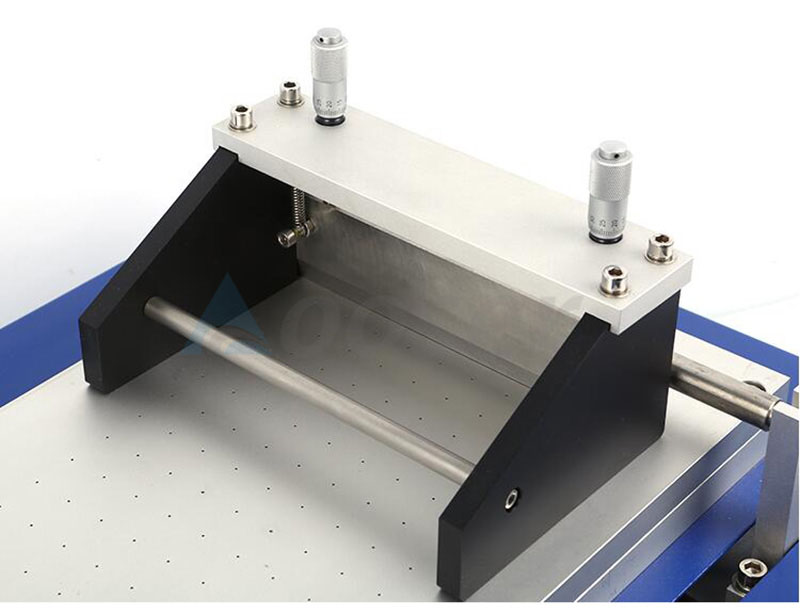

2)extrusion die geometric parameters, such as coating spacing H, die slit size w;

3)Coating process parameters, such as coating speed v, slurry feeding flow Q, etc.

In general, the coating machine uses a servo motor with a precision planetary reducer to drive the coating roller directly. The servo motor is to change the input signal into the angular displacement or angular speed output of the rotating shaft, and the steering and speed of the rotating shaft change with the voltage direction and size of the signal (pulse form). Therefore, the power supply fluctuation of the servo motor can also affect the coating accuracy, and the ordinary single-phase thyristor rectifier power supply has a very high fluctuation capacity at low speed, which will greatly reduce the coating quality.

At the same time, the battery slurry supply system will also cause instability in the coating amount, because the feed valve with low accuracy, the pneumatic diaphragm pump and the unstable air pressure of the pump will cause the slurry flow at the die head inlet and the pressure is unstable, and the slurry flow rate at the die head slit outlet will change.

In short, the main purpose of coating is to produce a uniform pole coating. Uniform and stable coating conditions must meet the following conditions:

1) The slurry property is stable, does not settle, viscosity, solid content and so on do not change;

2) The slurry feeding supply is stable, forming a uniform and stable flow state inside the die head or on the coating roll and transfer roll;

3) The coating process forms a stable flow field between the die head and the coating roller within the range of the coating window;

4) The walking foil is stable, no sliding, serious shaking and folding: tension and correction control.

Therefore, the polar sheet slurry coating equipment has become one of the key equipment for the successful development and production of lithium-ion batteries. The coating accuracy of the coating machine is inevitably related to the viscosity of the paste, the equipment and the coating process, and the quality of the coating is directly related to the quality of the battery. From the point of view of process flow, coating is the key process in the process of cell preparation, from the point of view of equipment value is the key process in the process of cell preparation (high-end series price of more than 10 million), from the point of view of nonlinear control is the key process in the process of cell preparation; Coating uniformity, consistency, alignment, baking stability, binder diffusivity, surface density stability are closely related to this. At the same time, the coating performance is directly related to the cost, pass rate and other practical indicators.

In the early days, lithium-ion battery coater is generally single-side coating, A roll of pole film twice operation, first A side coating dry after winding, and then B-side coating. Later, the equipment manufacturer developed A double-sided coating machine, mainly folding processing, coating die heads are set on both sides of the coating oven, coating side A on one side first, entering the oven to dry, and then coating side B on the other side, again entering the two-layer oven to dry, and then winding to complete the coating process on both sides.