Lithium Battery Sealing Machine Operation Guide

Introduction:

The Lithium Battery Sealing Machine is a specialized equipment designed for welding lithium batteries or large and irregularly shaped thermoplastic workpieces. It is primarily used to encapsulate the cells of lithium batteries, ensuring waterproof, dustproof, and shockproof properties. This machine boasts rapid setup, easy mold change, intuitive program control, and exceptional safety features, making it a reliable and durable plastic welding solution.

Key Features:

Efficiency: Automated encapsulation technology enables high-volume production with exceptional efficiency.

Superior Sealing: High-temperature fusion technology ensures a tight seal between the battery electrodes and the battery case.

Ease of Operation: Simple parameter adjustment allows for automatic completion of the encapsulation process.

High Safety Standards: Equipped with multiple safety protection systems, such as a bottom-up single-action safety door and automatic oil temperature detection, ensuring operator safety.

Components:

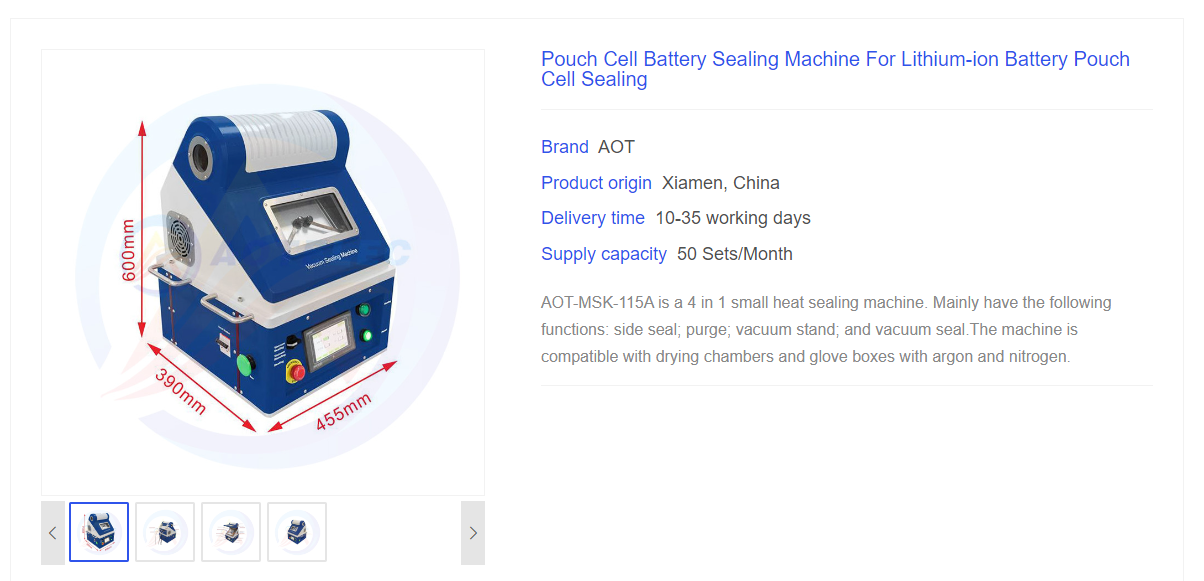

The Lithium Battery Sealing Machine typically comprises a battery clamping device, heating system, sealing mold, and control system. The battery clamping device secures the battery, the heating system heats the sealing mold, the sealing mold performs the sealing, and the control system orchestrates the entire operation.

Operation Guide:

1. Pre-Operation Checks:

Ensure the sealing machine is connected to a stable power source.

Verify that the worktable is clean and free of debris.

Prepare the battery packs and sealing materials, ensuring they meet the required length and width specifications.

2. Placing the Battery Pack:

Securely position the battery pack in the fixing clamp of the sealing machine.

Verify the correct polarity of the battery pack.

3. Setting Sealing Parameters:

Adjust the sealing parameters, including temperature, pressure, and time, based on the type of sealing material and battery pack specifications.

4. Initiating the Sealing Process:

Press the start button to initiate the sealing process. The machine will automatically heat the sealing material and apply pressure.

Wait for the sealing cycle to complete. The machine will automatically stop once the process is finished.

5. Quality Inspection:

After sealing, remove the battery pack from the machine.

Inspect the sealing line for uniformity, strength, and absence of gaps or damage.

Repeat the sealing process for any defective seals.

6. Cleaning and Maintenance:

Wipe the sealing table and accessories with a clean, soft cloth.

Regularly clean and maintain the sealing machine to ensure optimal performance and longevity.

Safety Precautions:

Always follow the manufacturer's operation manual and safety guidelines.

Wear appropriate personal protective equipment, such as gloves, safety glasses, and protective clothing.

Ensure the machine is switched off and all moving parts have stopped before performing any maintenance or cleaning tasks.

By adhering to these operation guidelines and safety precautions, you can ensure the safe and efficient operation of your Lithium Battery Sealing Machine.